Nuclear power cable insulating material of metal hydroxide-boron nitride hybridized filler/blended rubber and preparation method thereof

A hydroxide and cable insulation technology, applied in the field of cables, can solve problems such as poor compatibility, poor dispersion, and great influence on the mechanical properties of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

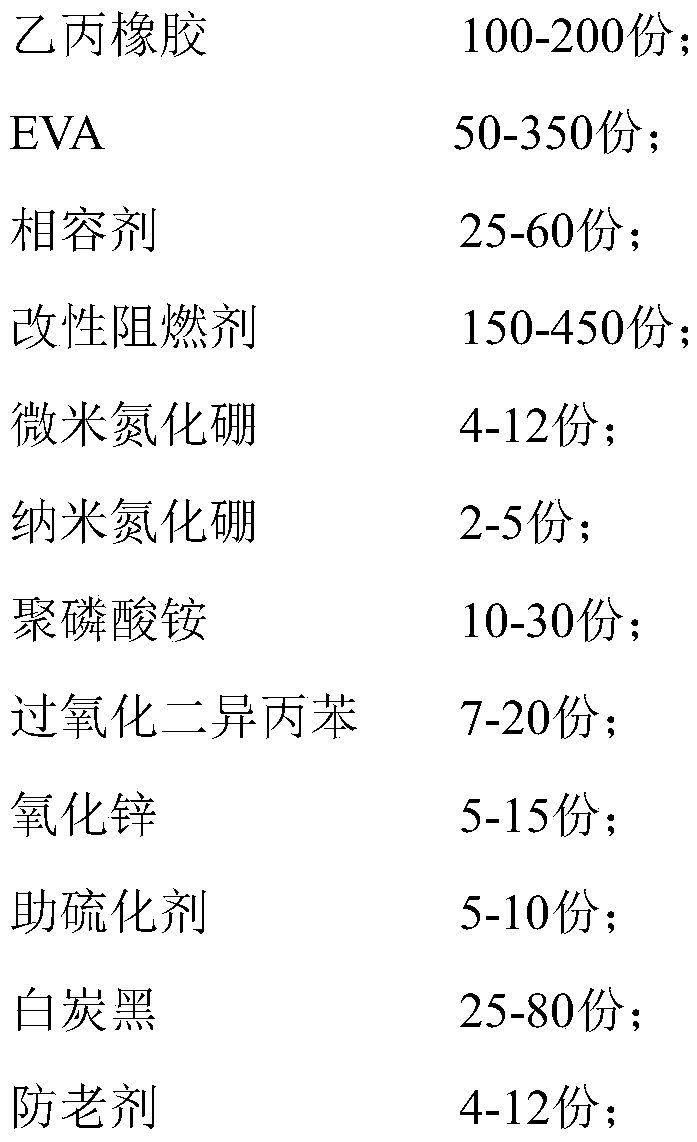

[0032] The components of the nuclear power cable insulation material in this embodiment are calculated by mass fraction as:

[0033]

[0034] The preparation method of the insulating material for nuclear power cables in this embodiment is as follows: first, the metal hydroxide grafted with methyl methacrylate and ionic liquid copolymer, micron boron nitride, nano boron nitride, ammonium polyphosphate, white carbon black and Put the anti-aging agent into the mixer, stir mechanically for 15-30 minutes until the mixture is uniform, and obtain the mixed filler; then masticate the ethylene-propylene rubber, EVA and compatibilizer in the open mill for 1-3 minutes, add the mixed filler, and ℃ for 10 minutes, then add dicumyl peroxide, zinc oxide, co-vulcanizing agent, and knead to obtain the insulation material for nuclear power cables. The performance tests of its hot press vulcanized products are shown in Attached Table 1.

Embodiment 2

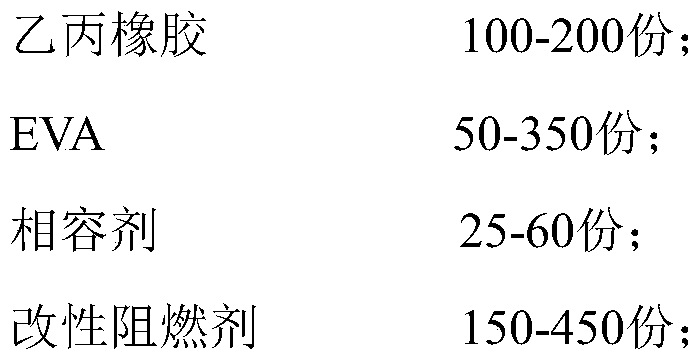

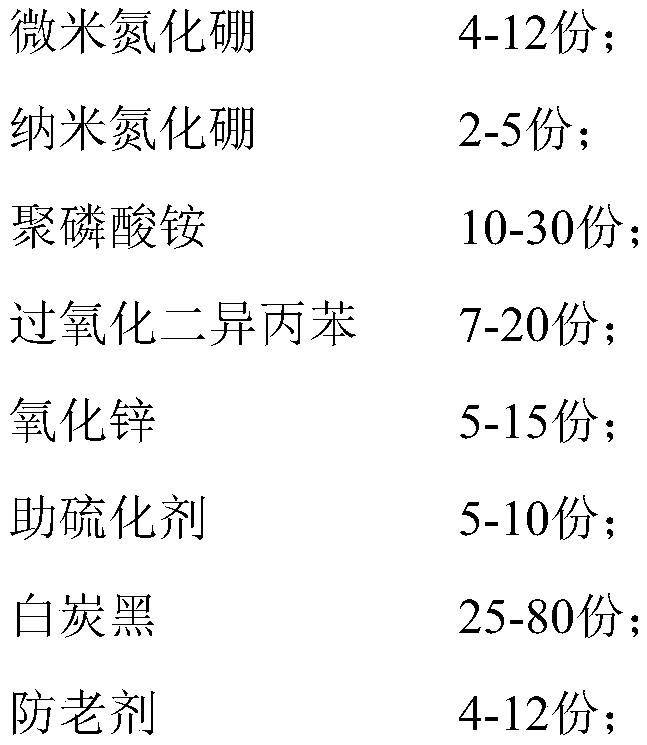

[0036] The components of the nuclear power cable insulation material in this embodiment are calculated by mass fraction as:

[0037]

[0038]

[0039] The preparation method of the insulating material for nuclear power cables in this embodiment is as follows: first, the metal hydroxide grafted with methyl methacrylate and ionic liquid copolymer, micron boron nitride, nano boron nitride, ammonium polyphosphate, white carbon black and Put the anti-aging agent into the mixer, stir mechanically for 15-30 minutes until the mixture is uniform, and obtain the mixed filler; then masticate the ethylene-propylene rubber, EVA and compatibilizer in the open mill for 1-3 minutes, add the mixed filler, and ℃ for 10 minutes, then add dicumyl peroxide, zinc oxide, co-vulcanizing agent, and knead to obtain the insulation material for nuclear power cables. The performance tests of its hot press vulcanized products are shown in Attached Table 1.

Embodiment 3

[0041] The components of the nuclear power cable insulation material in this embodiment are calculated by mass fraction as:

[0042]

[0043] The preparation method of the insulating material for nuclear power cables in this embodiment is as follows: first, the metal hydroxide grafted with methyl methacrylate and ionic liquid copolymer, micron boron nitride, nano boron nitride, ammonium polyphosphate, white carbon black and Put the anti-aging agent into the mixer, stir mechanically for 15-30 minutes until the mixture is uniform, and obtain the mixed filler; then masticate the ethylene-propylene rubber, EVA and compatibilizer in the open mill for 1-3 minutes, add the mixed filler, and ℃ for 10 minutes, then add dicumyl peroxide, zinc oxide, co-vulcanizing agent, and knead to obtain the insulation material for nuclear power cables. The performance tests of its hot press vulcanized products are shown in Attached Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com