Method for manufacturing 50A high-current fast recovery diode

A technology for recovering diodes and manufacturing methods, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., and can solve poor environmental adaptability such as poor PN junction passivation effect, temperature shock resistance, and large reverse recovery time and other problems, to achieve the effect of improving high temperature working stability, high long-term working reliability, and increasing the reverse voltage range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

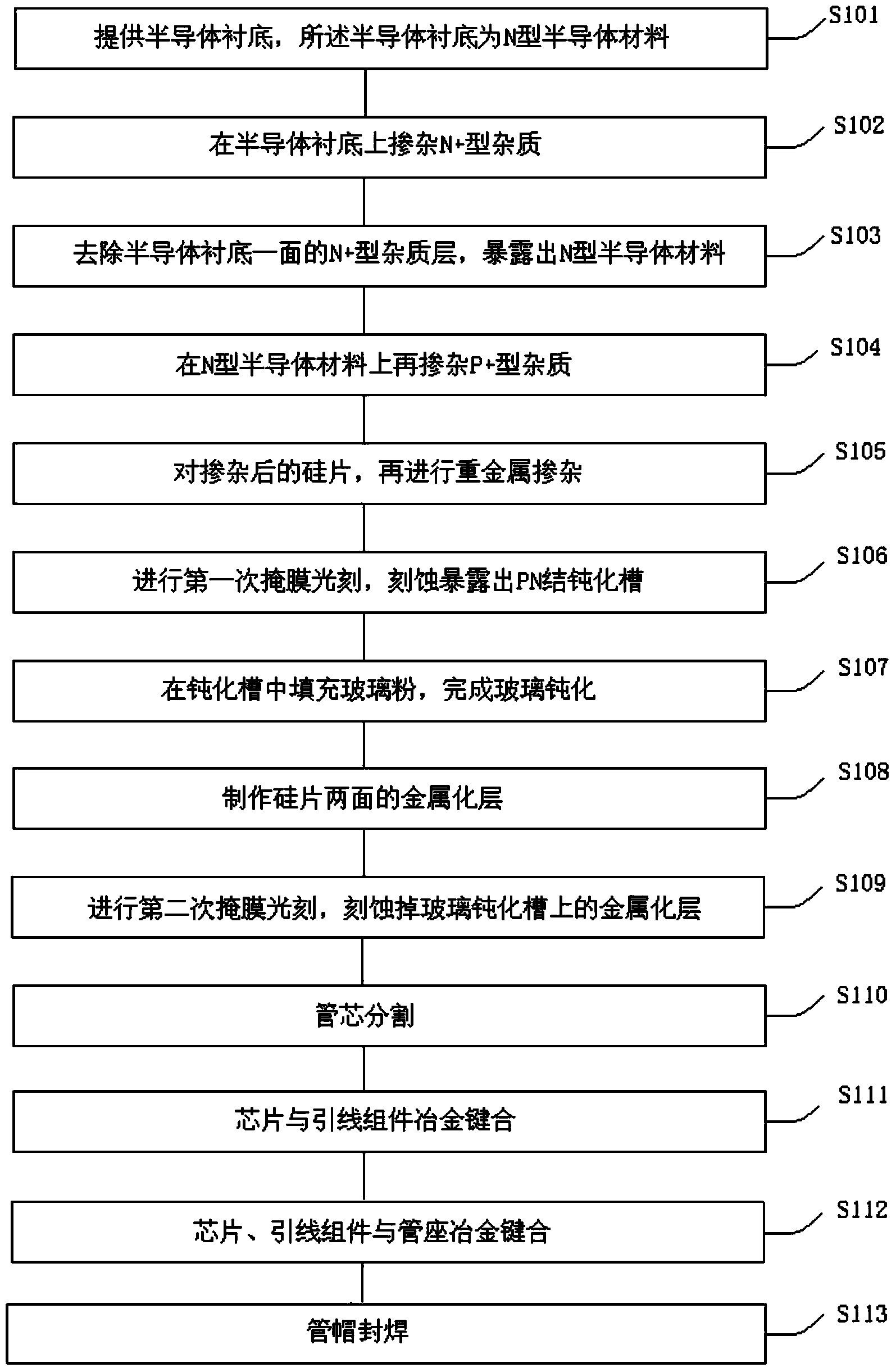

[0056] combine figure 1 The flow chart of the present invention illustrates the method step of the present invention:

[0057] A manufacturing method of a 50A high-current fast recovery diode, comprising the steps of:

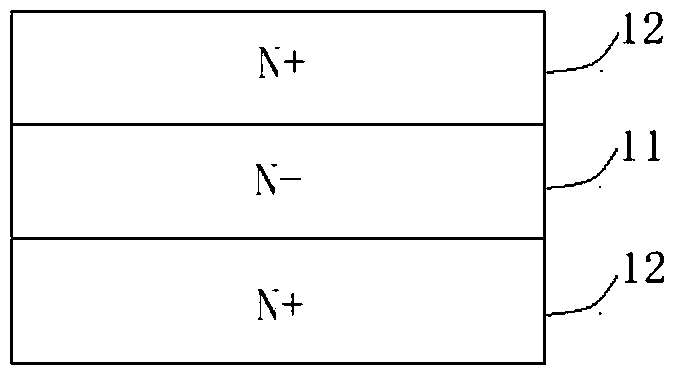

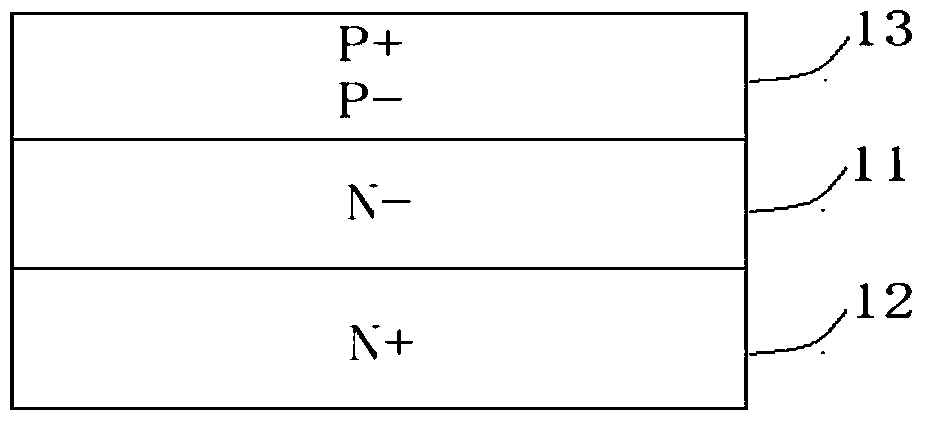

[0058] Step S101, providing a semiconductor substrate, the semiconductor substrate is an N-type semiconductor silicon material, and different material resistivities can be selected according to different reverse voltages; see figure 2 N-type silicon material layer 11.

[0059] Step S102, doping N on the N-type semiconductor substrate + Type impurities (compounds of phosphorus, such as P 2 o 5 or phosphine), which is generally achieved by high-temperature diffusion, and the diffusion temperature is between 1000°C a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com