Gallium oxide-based heterogeneous PN junction diode and preparation method thereof

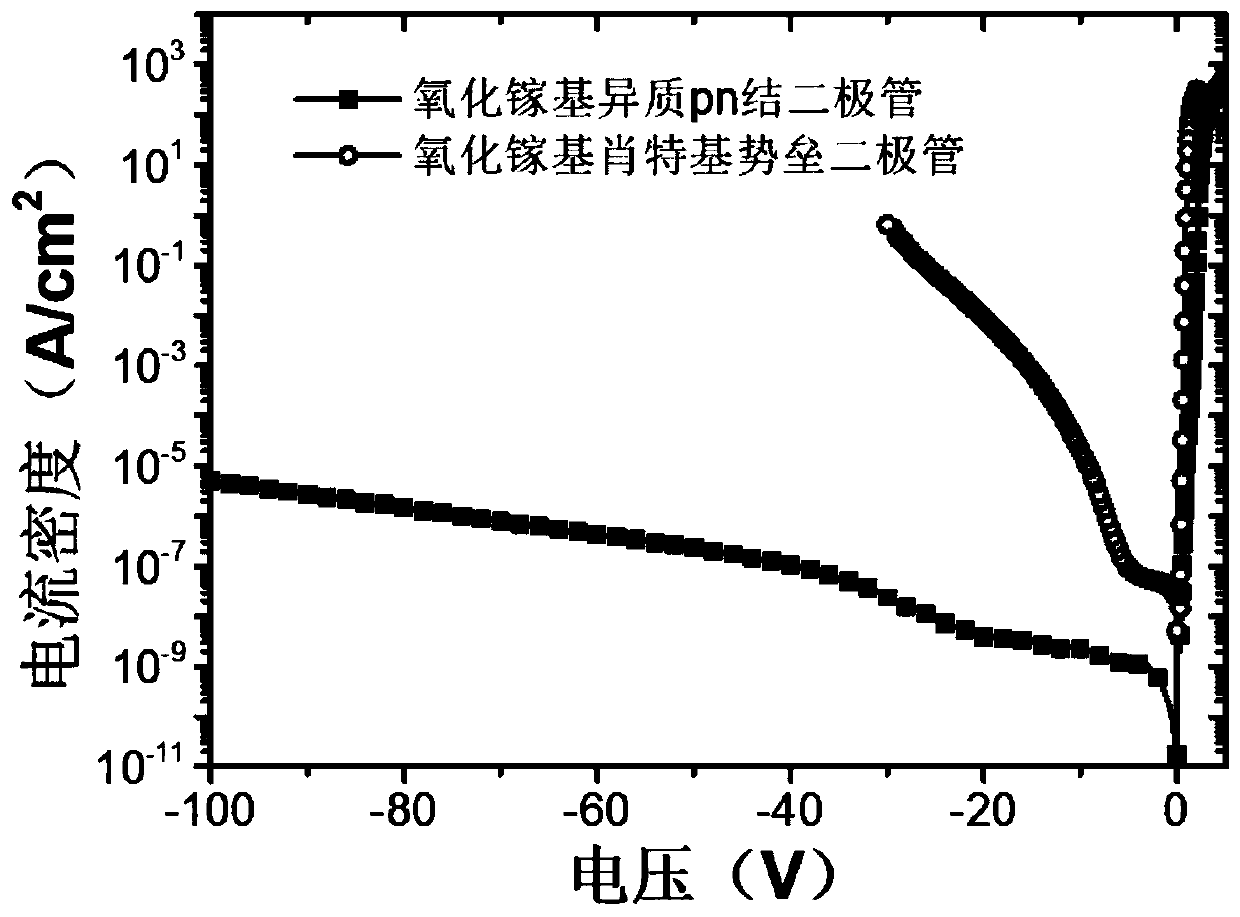

A PN junction diode, gallium oxide-based technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of large reverse leakage current of unipolar Schottky barrier diodes, inability to prepare power devices, shock Low breakdown voltage and other problems, to achieve the effect of low reverse leakage current, stable performance and high withstand voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

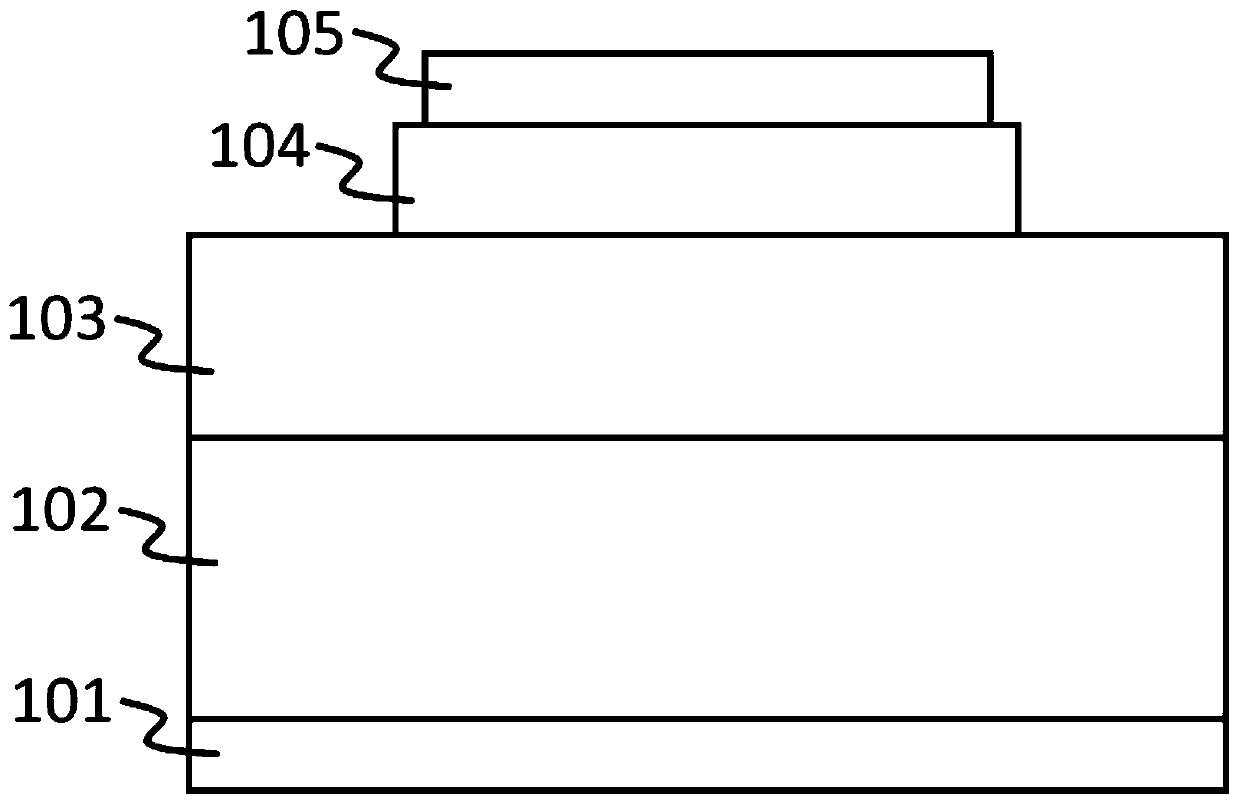

[0018] Such as figure 1 As shown, a gallium oxide-based heterogeneous PN junction diode described in the present invention includes a cathode electrode 101, an n-type doped gallium oxide substrate 102, and an n-type doped gallium oxide withstand voltage layer 103, which are sequentially stacked and connected, and also includes Anode electrode 105, p-type oxide semiconductor layer 104. One side of the p-type oxide semiconductor layer 104 is stacked and connected to the n-type doped gallium oxide withstand voltage layer 103, and the other side is stacked and connected to the anode electrode 105. The p-type oxide semiconductor layer 104 and the n-type doped The heterogallium oxide withstand voltage layer 103 forms a PN junction. The p-type oxide semiconductor layer 104 is an amorphous or polycrystalline structure with a hole concentration of 1×10 17 / cm 3 ~1×10 20 / cm 3 . The n-type doped gallium oxide withstand voltage layer 103 has a single crystal structure, and the dopi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com