Gallium oxide based hybrid PiN Schottky diode and preparation method thereof

A Schottky diode, gallium oxide technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of low breakdown voltage, inapplicability, poor temperature characteristics of Schottky barrier diodes, etc. The effect of good pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

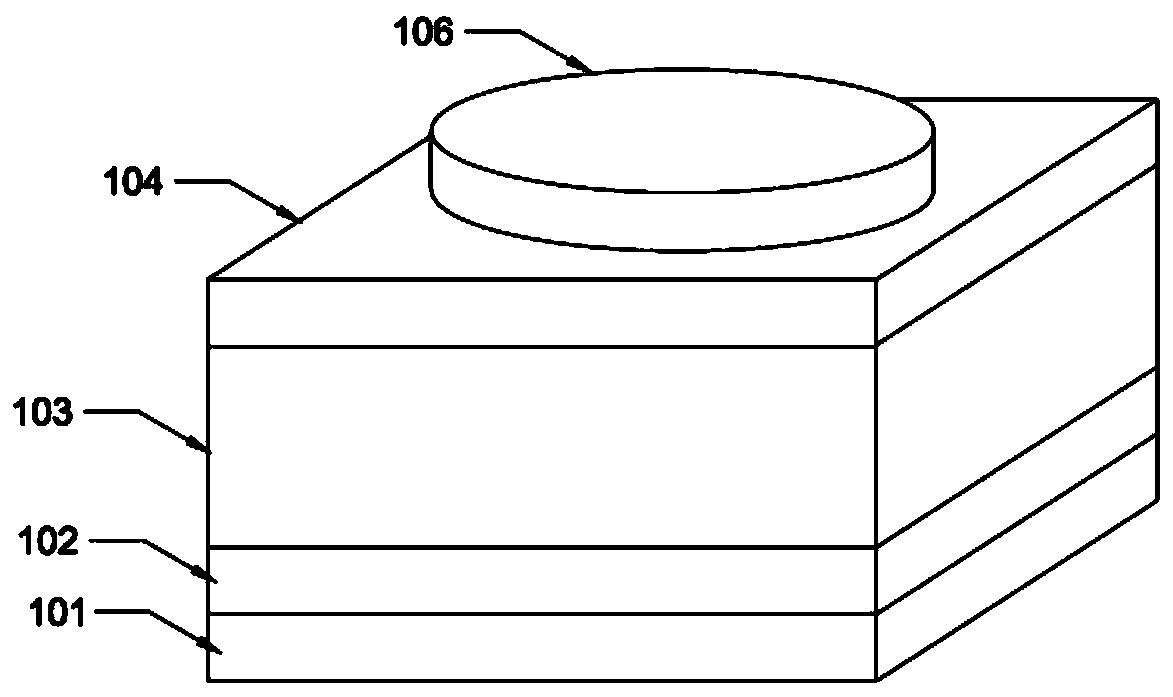

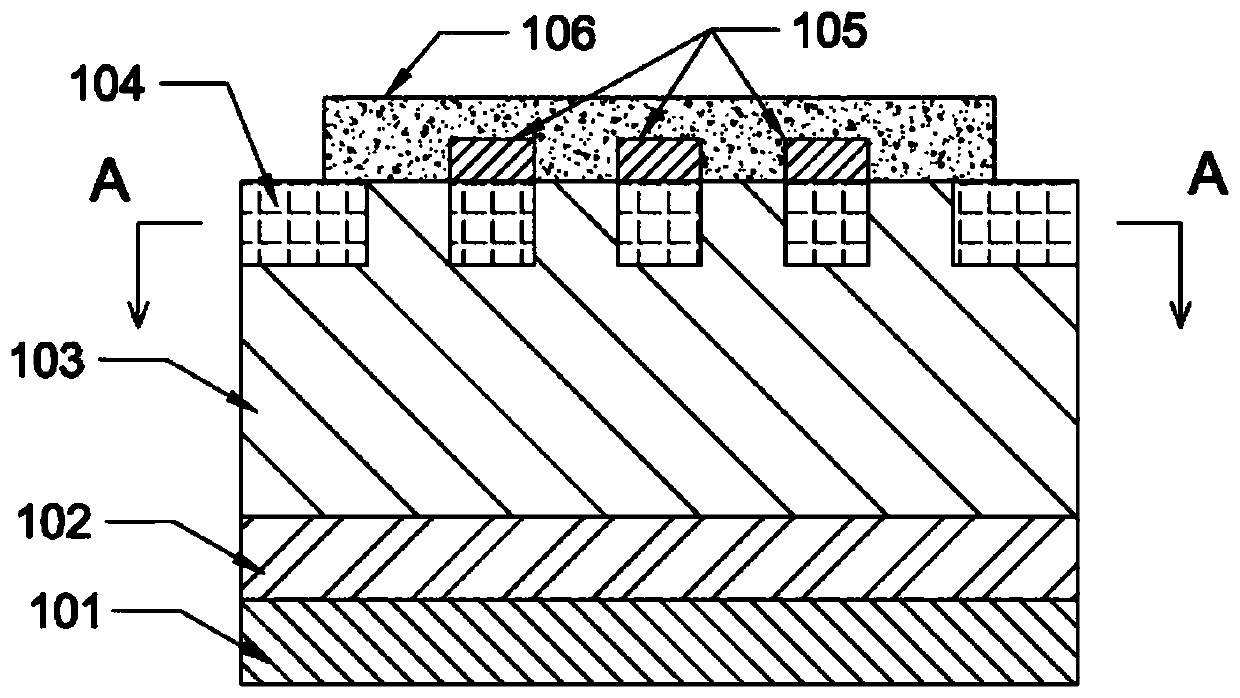

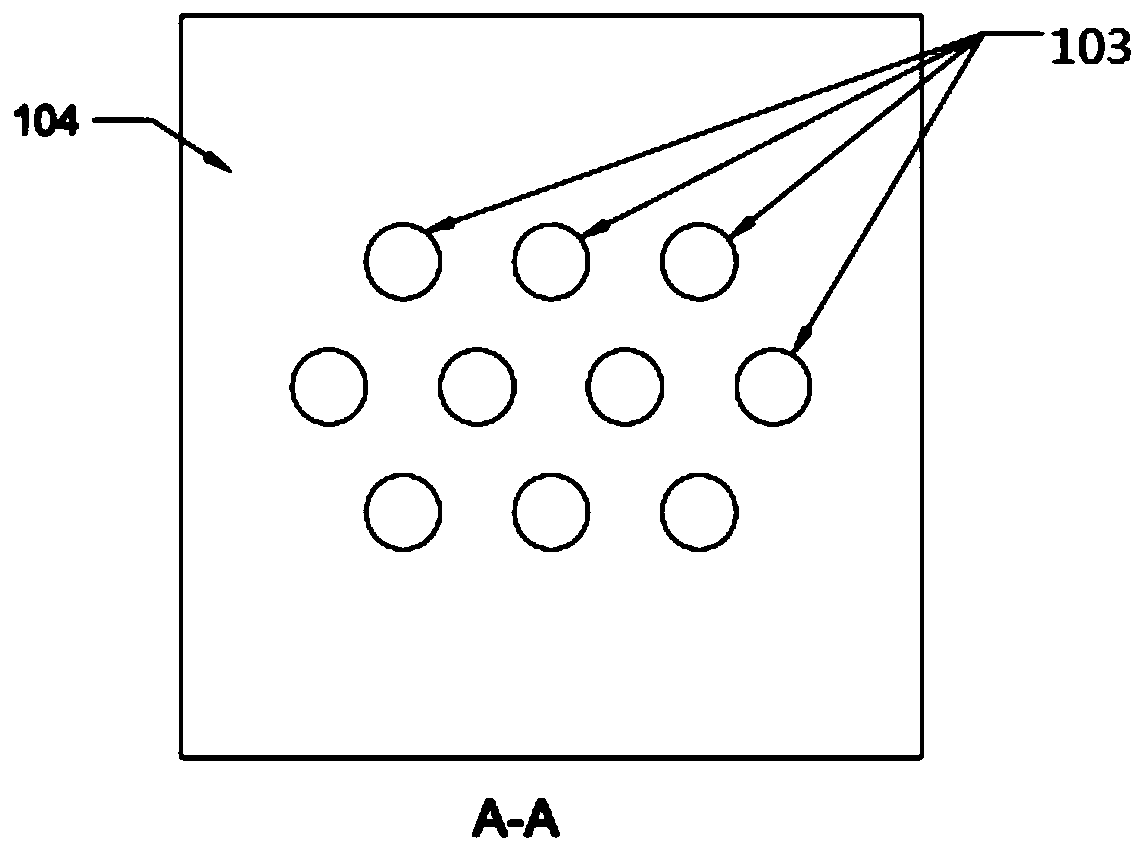

[0022] Such as Figure 1-3 As shown, a cathode electrode 101, an n-type doped gallium oxide substrate 102, a gallium oxide withstand voltage layer 103, and a p-type oxide semiconductor layer are sequentially stacked in a gallium oxide-based mixed PiN Schottky diode according to the present invention. 104 and the anode layer, the side of the gallium oxide withstand voltage layer 103 close to the p-type oxide semiconductor layer 104 is provided with a number of steps extending through the p-type oxide semiconductor layer 104, and the steps penetrate the p-type oxide semiconductor layer Layer 104 is then in contact with the anode layer; the step between the anode layer and the gallium oxide withstand voltage layer 103 is a Schottky contact; the anode layer and the p-type oxide semiconductor layer 104 are Schottky or ohmic touch. The n-type doped gallium oxide substrate 102 and the cathode electrode 101 are in ohmic contact. The anode layer includes a first anode electrode 105 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com