High strength rubber with radiation resistance and thermal aging resistance and preparation method thereof

A technology of heat aging resistance and radiation resistance, which is applied in the fields of new rubber and its preparation, high-strength rubber and its preparation, and can solve the problems of inability to improve radiation resistance, decline in rubber mechanical properties, and limited radiation resistance. Achieve good social and economic benefits, good mechanical properties, excellent radiation resistance and heat aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

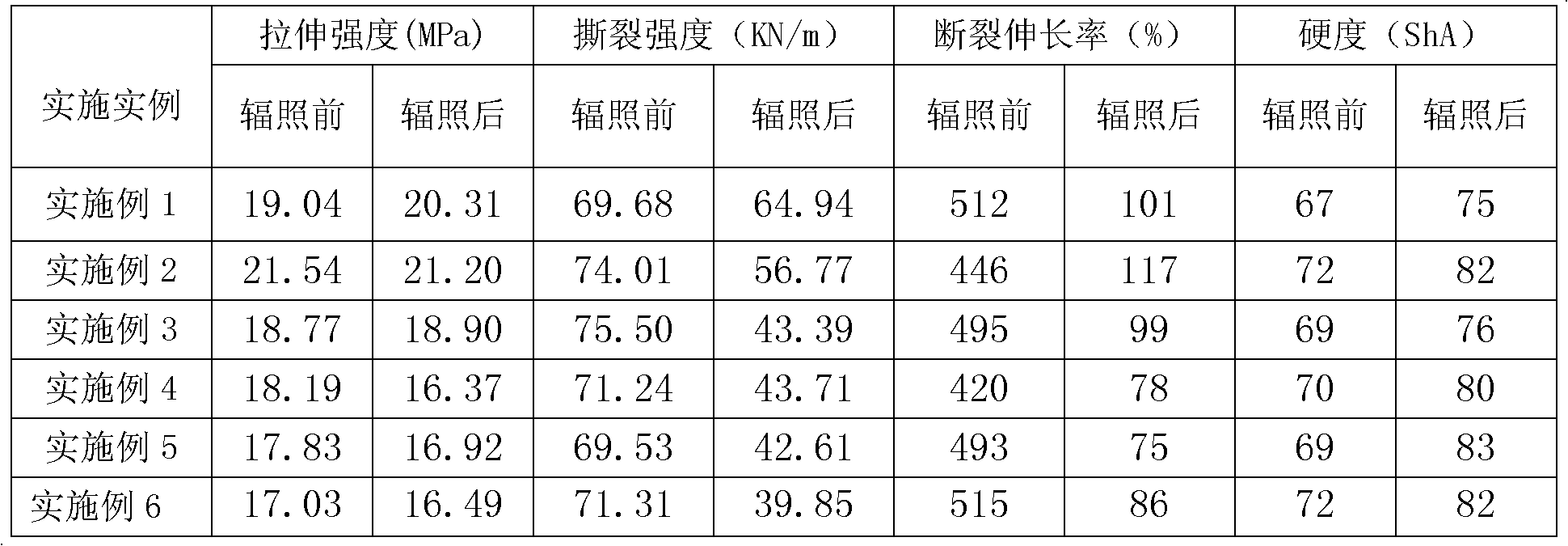

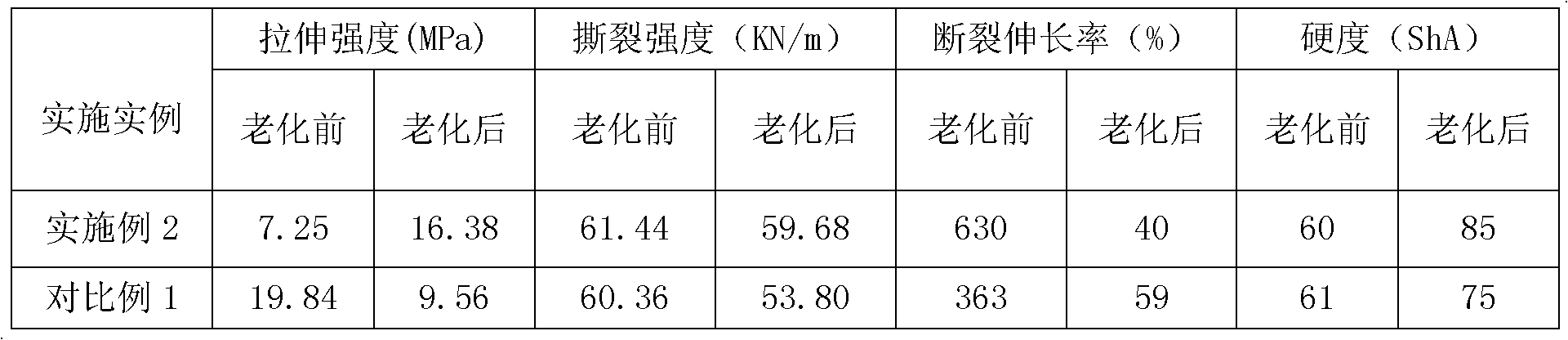

Examples

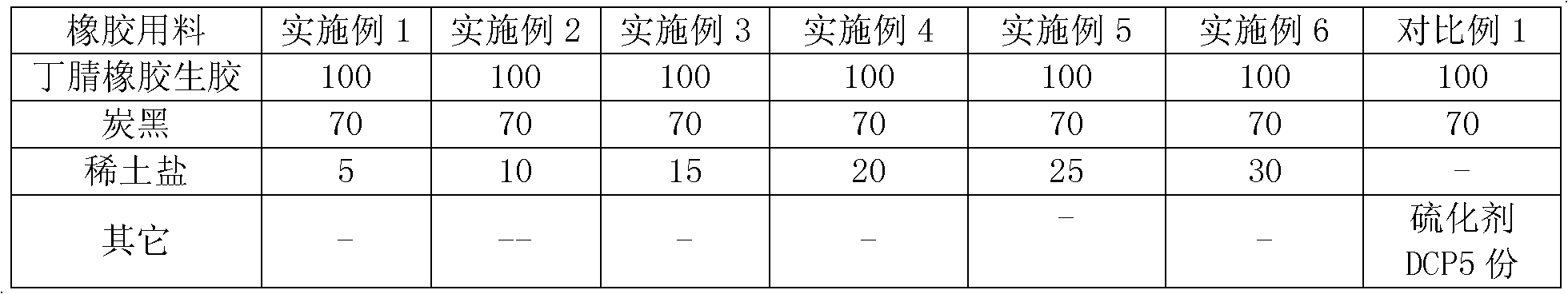

Embodiment 1

[0025] Take the following components in parts by weight (kg): 100 parts of nitrile rubber raw rubber (nitrile rubber raw rubber, its acrylonitrile mass fraction is 41%), 5 parts of rare earth salts (gadolinium chloride), 70 parts of strengthening agent (carbon black, N220 produced by American Cabot Company).

[0026] First, add the raw nitrile rubber, carbon black, and rare earth salts of the component amount to the mixer in sequence, and knead at room temperature for 30 minutes, then heat-treat the kneaded material at 190°C for 1 hour, and knead again. Evenly, the rubber base material with radiation resistance can be obtained, and the rubber product with radiation resistance can be obtained by molding and vulcanizing the base material.

Embodiment 2

[0028] The specific operation method is the same as that of Example 1, except that the component amount of gadolinium chloride is changed to 10 parts in the ratio of the rare earth salt component.

Embodiment 3

[0030] The specific operation method is the same as that of Example 1, except that the component amount of gadolinium chloride is changed to 15 parts in the proportion of rare earth salt components.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com