Processing technology of vacuum forming box of new energy automobile

A technology of new energy vehicles and processing technology, which is applied in the field of processing technology of new energy vehicle blister boxes, can solve the problems of uneven thickness of blister boxes, affecting the quality of blister boxes, and lack of radiation resistance, etc., achieving simple structure, The effect of high yield and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A processing technology for a new energy automobile blister box, comprising the following steps:

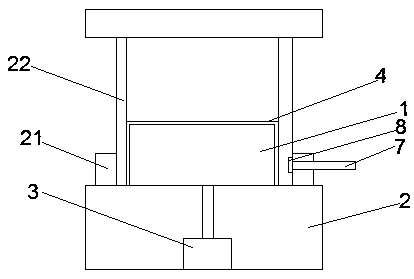

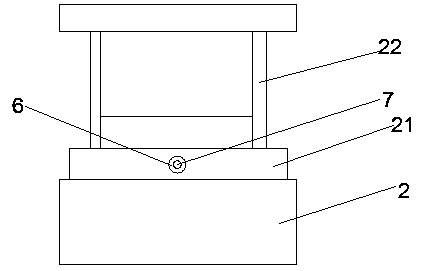

[0027] (1) Make a mold: Make a mold 1 according to the required shape, and place it under the blister machine 2 for standby, and the mold 1 can move up and down driven by the driving device 3;

[0028] (2) Production materials: mix PVC resin, silicone oil, titanium dioxide and alumina and put them in an extruder to obtain the base sheet 4;

[0029] (3) Blister forming: place the base sheet 4 in the fixed frame 21 of the blister machine 2 for fixing, after heating, the mold 1 moves up under the drive of the driving device 3, and lifts the base sheet 4, the The upper two sides of the blister machine have a lower pressing block 22 used in conjunction with the mold 1, and the lower pressing block 22 is pressed down to obtain a blister box 5;

[0030] (4) Surface treatment: spray a layer of surface protection liquid on the surface of the blister box 5, and place the sprayed bl...

Embodiment 2

[0037] A processing technology for a new energy automobile blister box, comprising the following steps:

[0038] (1) Make a mold: Make a mold 1 according to the required shape, and place it under the blister machine 2 for standby, and the mold 1 can move up and down driven by the driving device 3;

[0039] (2) Production materials: mix PVC resin, silicone oil, titanium dioxide and alumina and put them in an extruder to obtain the base sheet 4;

[0040] (3) Blister forming: place the base sheet 4 in the fixed frame 21 of the blister machine 2 for fixing, after heating, the mold 1 moves up under the drive of the driving device 3, and lifts the base sheet 4, the The upper two sides of the blister machine have a lower pressing block 22 used in conjunction with the mold 1, and the lower pressing block 22 is pressed down to obtain a blister box 5;

[0041] (4) Surface treatment: spray a layer of surface protection liquid on the surface of the blister box 5, and place the sprayed bl...

Embodiment 3

[0047] A processing technology for a new energy automobile blister box, comprising the following steps:

[0048] (1) Make a mold: Make a mold 1 according to the required shape, and place it under the blister machine 2 for standby, and the mold 1 can move up and down driven by the driving device 3;

[0049] (2) Production materials: mix PVC resin, silicone oil, titanium dioxide and alumina and put them in an extruder to obtain the base sheet 4;

[0050] (3) Blister forming: place the base sheet 4 in the fixed frame 21 of the blister machine 2 for fixing, after heating, the mold 1 moves up under the drive of the driving device 3, and lifts the base sheet 4, the The upper two sides of the blister machine have a lower pressing block 22 used in conjunction with the mold 1, and the lower pressing block 22 is pressed down to obtain a blister box 5;

[0051] (4) Surface treatment: spray a layer of surface protection liquid on the surface of the blister box 5, and place the sprayed bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com