Waterproof breathable film and preparation method thereof

A waterproof and breathable film technology, which is applied in the field of plastic films, can solve the problems of poor compatibility between inorganic fillers and polyethylene, inability to guarantee the waterproof and breathable ability of the film, and poor quality of micropore forming, so as to improve the waterproof and breathable performance and ensure waterproof and breathable Performance, the effect of improving binding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

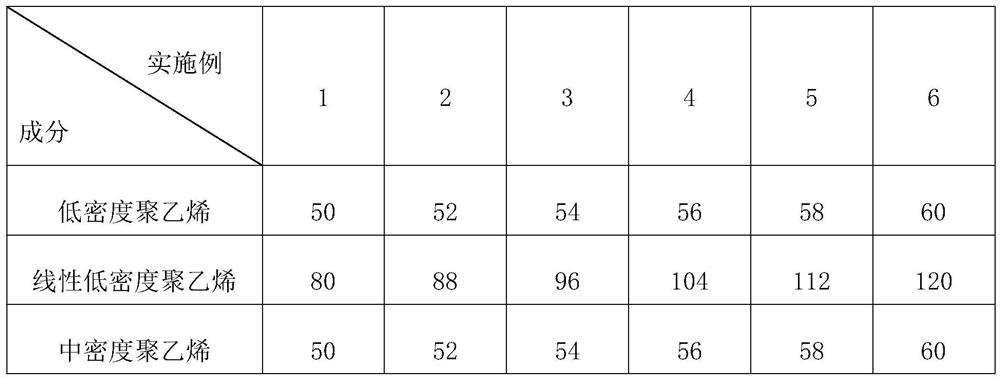

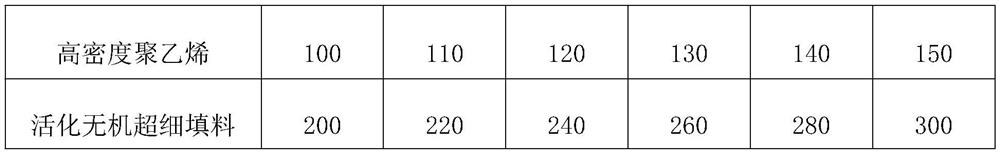

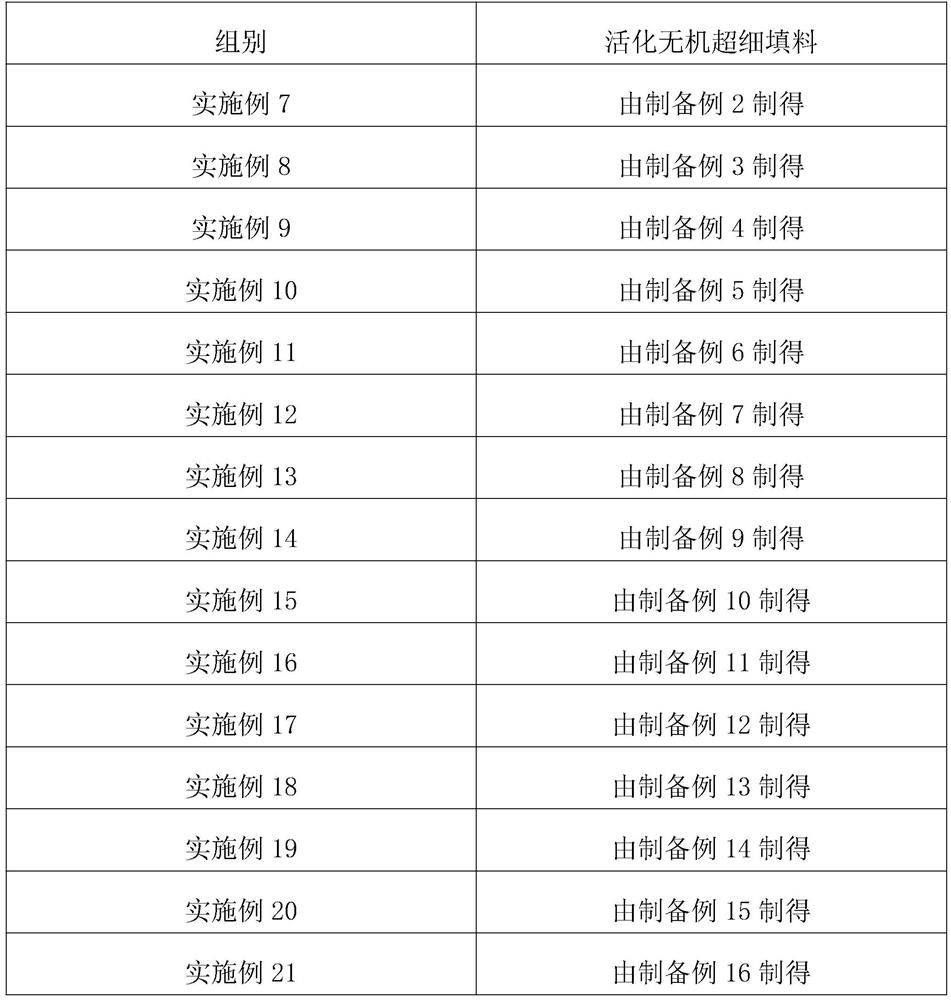

Examples

preparation example 1

[0062] An activated inorganic ultrafine filler is prepared by the following preparation steps:

[0063] a. Pretreatment: Preheat the inorganic ultrafine filler to 90°C, and vacuum stir and dry the inorganic ultrafine filler at a speed of 2000r / min. After the water content is lower than 0.3%, press 1:0.01 The weight ratio is added to the coupling agent, and the pretreatment is carried out for 6 minutes;

[0064] Wherein the coupling agent is a titanate coupling agent;

[0065] The particle size of the inorganic ultrafine filler is 1000-2000 mesh;

[0066] Inorganic superfine filler is light calcium carbonate;

[0067] b. Activation treatment: Activate the pretreated inorganic ultrafine filler and the activated sol at a weight ratio of 1:0.2 for 15 minutes at a pH of 7, a temperature of 140°C, and a rotational speed of 300r / min;

[0068] The activated sol is composed of sodium bicarbonate and amino resin in a weight ratio of 1:1.

preparation example 2

[0070] An activated inorganic ultra-fine filler, the difference from Preparation Example 1 is that the specific treatment steps of a are as follows: first preheat the inorganic ultra-fine filler to 100 ° C, and conduct the inorganic ultra-fine filler at a speed of 3000r / min Vacuum stirring and drying, after the water content is lower than 0.3%, then add coupling agent according to the weight ratio of 1:0.02, and carry out pretreatment for 8 minutes.

preparation example 3

[0072] An activated inorganic ultra-fine filler, the difference from Preparation Example 1 is that the specific treatment steps of a are as follows: first preheat the inorganic ultra-fine filler to 110 ° C, and conduct the inorganic ultra-fine filler at a speed of 4000r / min Vacuum stirring and drying, after the water content is lower than 0.3%, then add coupling agent according to the weight ratio of 1:0.025, and carry out pretreatment for 9 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| hydrostatic pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com