Organosilicon weatherproof batch scraped natural stone-like paint and preparation method thereof

A technology of weather-resistant scratch-resistant and real stone paint, which is applied in the field of silicone weather-resistant scratch-resistant natural stone paint and its preparation, can solve the problems of relatively large impact on stain resistance, easy serious dust accumulation, rough paint film, etc., to achieve Better appearance, energy saving, larger contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

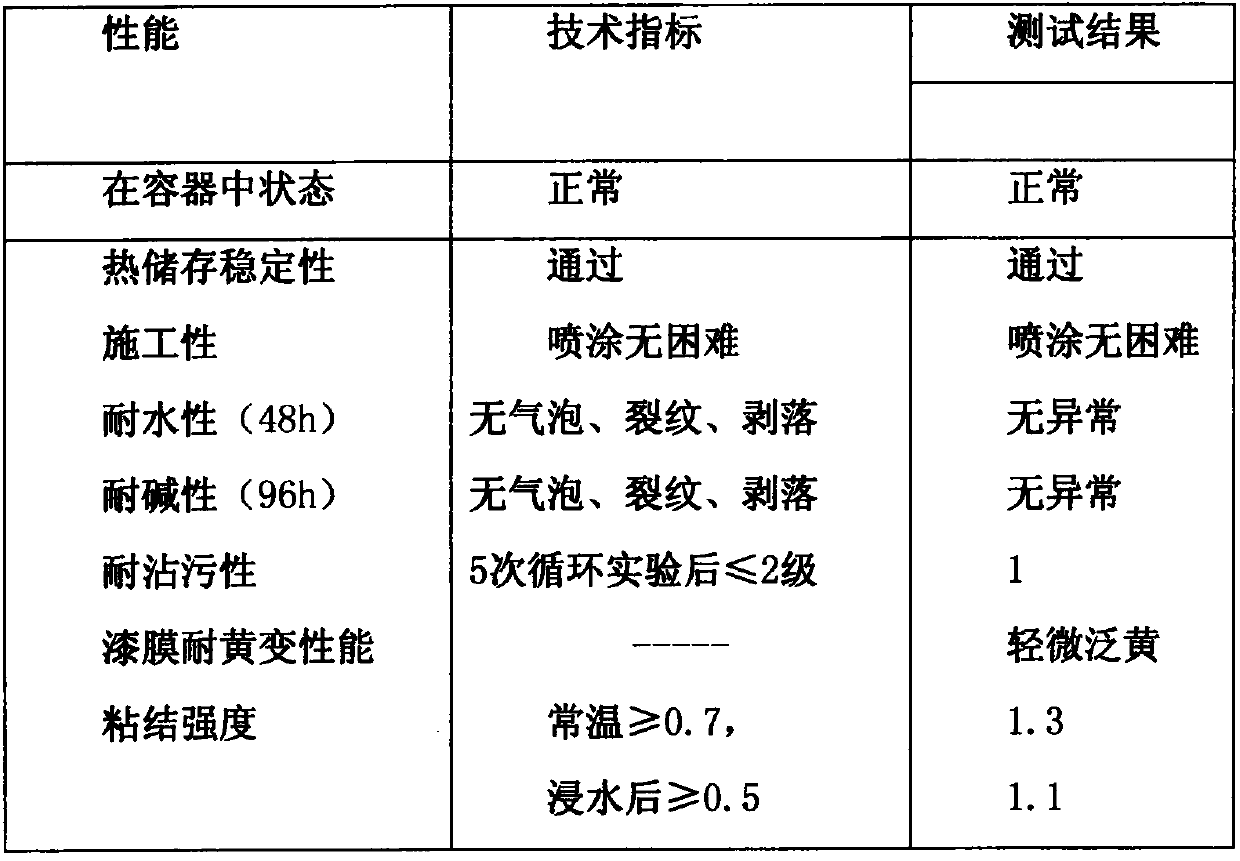

Embodiment 1

[0037] A silicone weather-resistant scratch-off natural stone paint is prepared from 25 wt% of component A, 3 wt% of component B and 72 wt% of component C.

[0038] Taking component A as 100wt%, said component A consists of 37.45wt% water, 1wt% hydroxyethyl cellulose ether (Clariant YP30000), 0.15 wt%, film former organosiloxane modified acrylic emulsion (Shenuo 8861) 10wt%, film former silicon emulsion (Badfu 996AD) 45wt%, film forming aid alcohol ester twelve 2.5wt%, film forming aid Auxiliary ethylene glycol 3wt%, silicone defoamer (San Danuoxiang 1340) 0.2wt%, bactericide isothiazolinone mixture (Dow 631) 0.4wt%, and polyurethane type thickener (Tao His ASE60) 0.3wt% composition.

[0039] Based on 100wt% of component B, said component B consists of 97.6wt% of water, 2wt% of organically modified thickener (Suzhou Sinoma ZC06Z) and 0.4wt of fungicide isothiazolinone mixture (Dow 631) %composition.

[0040] The C component is composed of natural colored sand.

[0041] The...

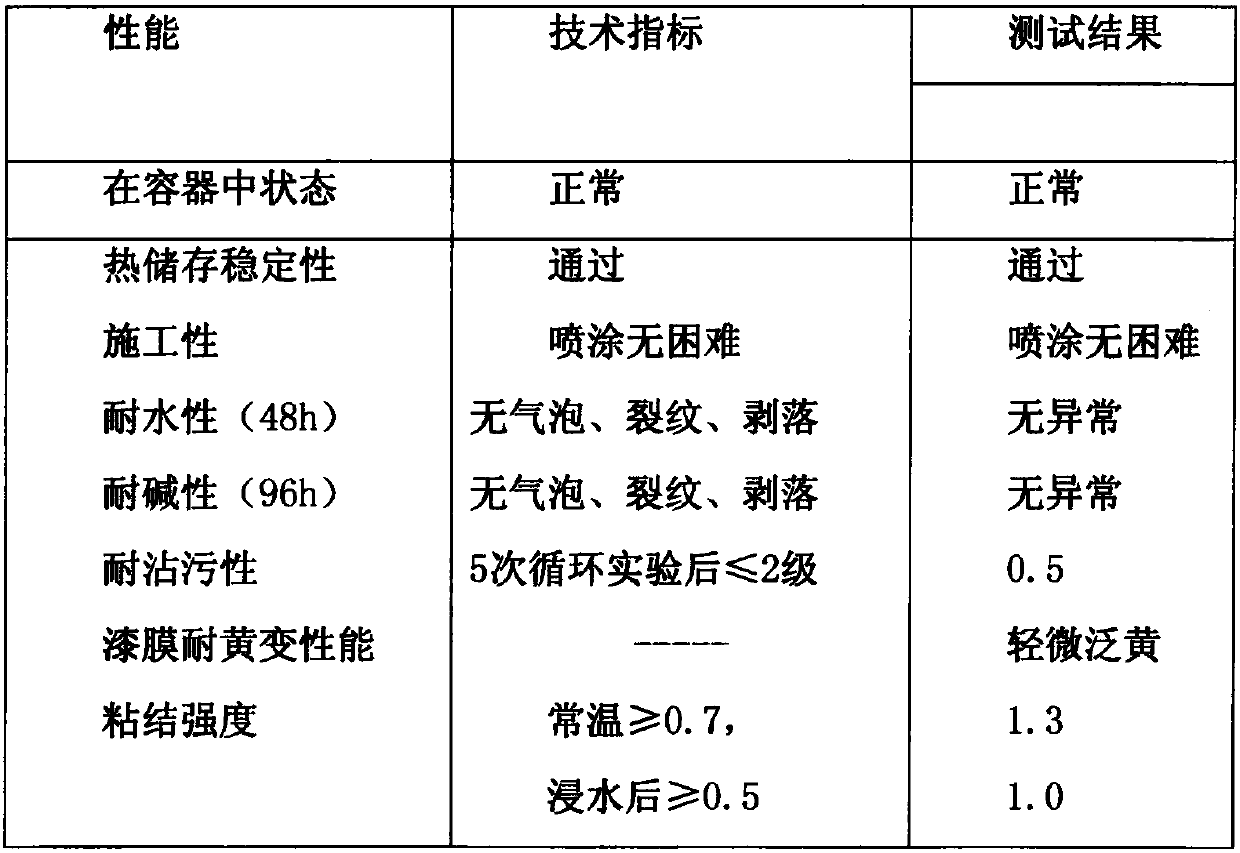

Embodiment 2

[0049] A silicone weather-resistant scratch-off natural stone paint is prepared from 25 wt% of component A, 4 wt% of component B and 71 wt% of component C.

[0050] Based on 100 wt% of component A, the component A consists of 32.3 wt% of water, 0.9 wt% of hydroxyethyl cellulose ether (Clariant YP30000), a pH regulator (35% aqueous sodium hydroxide solution) 0.2wt%, film former organosiloxane modified acrylic emulsion (Shenuo 8861) 14wt%, film former silicon emulsion (Badfu 996AD) 45wt%, film forming aid alcohol ester twelve 3wt%, film forming aid Auxiliary ethylene glycol 3.5wt%, siloxane defoamer (San Danuoxiang 1340) 0.25wt%, bactericide isothiazolinone mixture (Dow 631) 0.5wt%, and polyurethane thickener ( Dow ASE60) 0.35wt% composition.

[0051] Based on 100wt% of component B, said component B consists of 97.6wt% of water, 2wt% of organically modified thickener (Suzhou Sinoma ZC06Z) and 0.4wt of fungicide isothiazolinone mixture (Dow 631) %composition.

[0052] The C co...

Embodiment 3

[0061] A silicone weather-resistant batch scratch type natural stone paint is prepared from 25 wt% of component A, 5 wt% of component B and 70 wt% of component C.

[0062] Based on 100 wt% of component A, the component A consists of 27.2 wt% of water, 0.8 wt% of hydroxyethyl cellulose ether (Clariant YP30000), a pH regulator (35% aqueous sodium hydroxide solution) 0.2wt%, film former organosiloxane modified acrylic emulsion (Shenuo 8861) 18wt%, film former silicon emulsion (Badfu 996AD) 45wt%, film forming aid alcohol ester twelve 3.5wt%, auxiliary Membrane aid ethylene glycol 4wt%, siloxane defoamer (San Danuoxiang 1340) 0.3wt%, bactericide isothiazolinone mixture (Dow 631) 0.6wt%, and polyurethane thickener ( Dow ASE60) 0.4wt% composition.

[0063] Based on 100wt% of component B, said component B consists of 97.6wt% of water, 2wt% of organically modified thickener (Suzhou Sinoma ZC06Z) and 0.4wt of fungicide isothiazolinone mixture (Dow 631) %composition.

[0064] The C c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com