Polyurethane self-adhesive film waterproof roll as well as preparation method and application thereof

A self-adhesive film, waterproof membrane technology, applied in the direction of adhesives, film/sheet release liners, modified epoxy resin adhesives, etc. The problems of poor permeability, mechanical properties and fatigue resistance can improve heat resistance, crosslink density, and high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

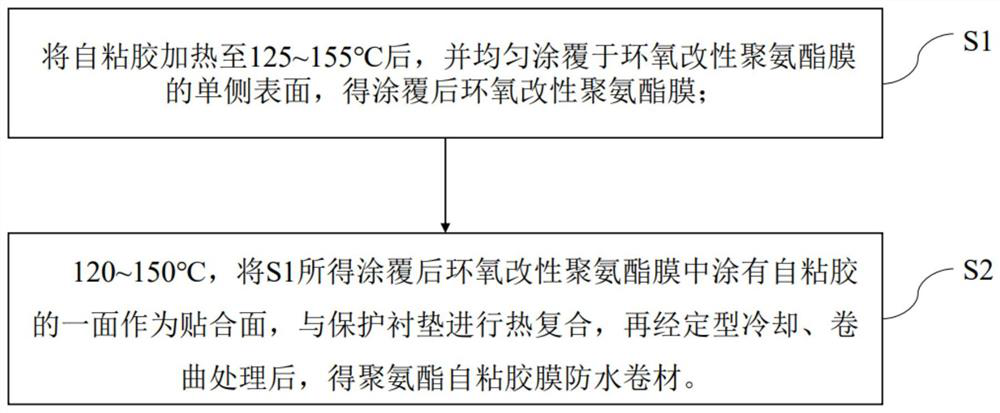

[0032] The preparation method of the polyurethane self-adhesive film waterproof coiled material of this embodiment, comprises the following steps:

[0033] S1: Heat the self-adhesive to 125-155°C, and evenly coat the surface of one side of the epoxy-modified polyurethane film to obtain the coated epoxy-modified polyurethane film;

[0034] S2: 120~150℃, use the self-adhesive-coated side of the coated epoxy-modified polyurethane film obtained in S1 as the bonding surface, thermally compound it with the protective liner, and then undergo shaping cooling and curling treatment to obtain Polyurethane self-adhesive membrane waterproofing membrane.

[0035] The application of the polyurethane self-adhesive film waterproof coiled material of this embodiment in underground waterproofing projects.

Embodiment 1

[0037] S1: Disperse 10 parts of hydroxymethylphenylphosphinic acid in 20 parts of tetrahydrofuran in parts by mass, and mix with 40 parts of polyether polyurethane prepolymer, 15 parts of epoxy acrylate, and 5 parts of fluorinated epoxy resin After uniformity, heat to 50°C for pre-reaction for 0.5h, then raise the temperature to 70°C, add 1 part of bis-dimethylaminoethyl ether, heat and stir for 3h, then pour into the mold, heat and press at 90°C for 1h, and then heat up to Continue to heat and press at 130°C for 0.5h to make an epoxy-modified polyurethane film with a thickness of 0.2mm;

[0038] S2: Weigh 20 parts of epoxy acrylate resin, 8 parts of EVA resin, 6 parts of thermoplastic elastomer SBS, and 3 parts of styrene-butadiene rubber in order by mass parts, and then mix them uniformly to obtain self-adhesive glue;

[0039] S3: Heat the self-adhesive to 125°C, and evenly coat the surface of one side of the epoxy-modified polyurethane film with a coating thickness of 0.1 m...

Embodiment 2

[0042] S1: Disperse 12.5 parts of bis(4-carboxyphenyl)phenylphosphine oxide in 25 parts of tetrahydrofuran by mass parts, and then mix with 50 parts of polyether polyurethane prepolymer, 17.5 parts of epoxy acrylate, 7.5 parts of fluorinated After the epoxy resin is mixed evenly, heat it to 50°C for pre-reaction for 1 hour, then raise the temperature to 75°C, add 1.5 parts of bis-dimethylaminoethyl ether, keep warm and stir for 5 hours, then pour it into the mold, and heat and press at 100°C for 1.5 hours , and then heated up to 140°C to continue hot-press curing for 1 hour to make an epoxy-modified polyurethane film with a thickness of 0.4mm;

[0043] S2: Weigh 25 parts of epoxy acrylate resin, 10 parts of EVA resin, 8 parts of thermoplastic elastomer SBS, and 4 parts of styrene-butadiene rubber in order by mass parts, and then mix them uniformly to obtain self-adhesive glue;

[0044] S3: Heat the self-adhesive to 140°C, and evenly coat the surface of one side of the epoxy-mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com