Cross composite membrane with TPU membrane and manufacturing method of cross composite membrane

A manufacturing method and composite film technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of poor impact resistance of TPU composite films, reduced scope of application, and difficulty in guaranteeing strength. Improve waterproof and breathable performance, improve convenience of use, and good waterproof and breathable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

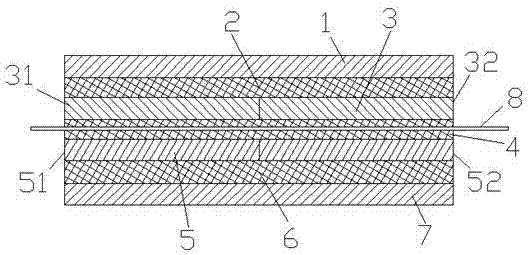

[0031] A kind of manufacture method of the cross composite film with TPU film, comprises the following steps:

[0032] 1) Preparation of bottom material: use film blowing equipment to manufacture breathable TPU film, PE film and PP film in sequence;

[0033] 2) One-time lamination: The breathable TPU film, PU adhesive, PP film and PE film are combined in the compound machine, and the PP film and the PE film are arranged on the upper or lower surface of the TPU film at intervals to make a three-layer one-time Composite film, the primary composite film is slit by a rotary slitter, 45︒ angle helical slitting, winding;

[0034] 3) Secondary lamination: take two rolls of the primary composite film and put them into the compound machine after aligning them. Lay transparent nylon mesh in the middle, and ensure that the breathable TPU film of the primary composite film is on the outside, and the two sides of the transparent nylon mesh extend to the outside of the primary composite fil...

Embodiment 2

[0037] A kind of manufacture method of the cross composite film with TPU film, comprises the following steps:

[0038] 1) Preparation of bottom material: use film blowing equipment to manufacture breathable TPU film, PE film and PP film in sequence;

[0039] 2) One-time lamination: The breathable TPU film, PU adhesive and PE film are compounded in the compound machine to form a three-layer primary compound film. Two PE films are arranged on the upper or lower surface of the TPU film at intervals. The primary composite film is slit by a rotary slitter at a 45︒ angle spiral, and wound up;

[0040] 3) Secondary bonding: align the primary composite film and two PP films and put them into the compound machine, lay transparent nylon mesh in the middle, and place the two PP films on the surfaces of the two PE films respectively, and ensure the breathable TPU of the primary composite film The film is on the outside, and the two sides of the transparent nylon mesh extend to the outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com