Preparation process of 3D pattern anti-leakage high-breathability film

A preparation process, high-permeability technology, applied in flat products, applications, household appliances, etc., can solve the problems of insufficiently obvious calendered pattern of breathable film, lack of three-dimensional sense of pattern, lack of vividness of pattern, etc., to increase stiffness and strengthen 3D Effect, clear embossing pattern, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

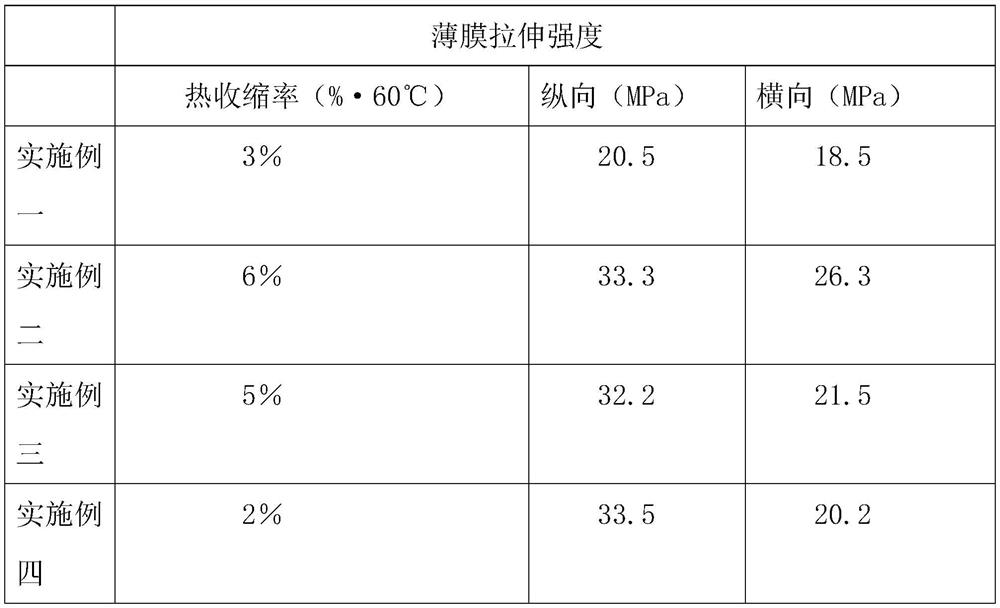

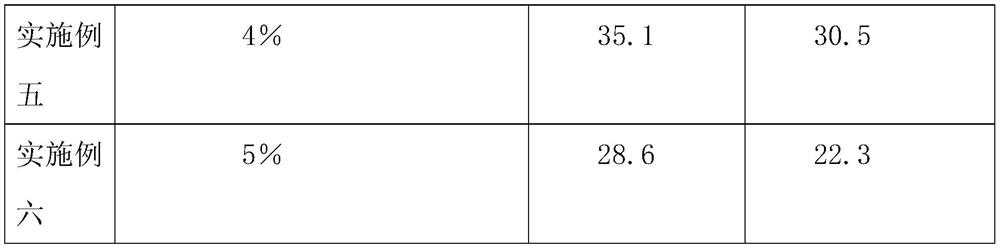

Embodiment 1

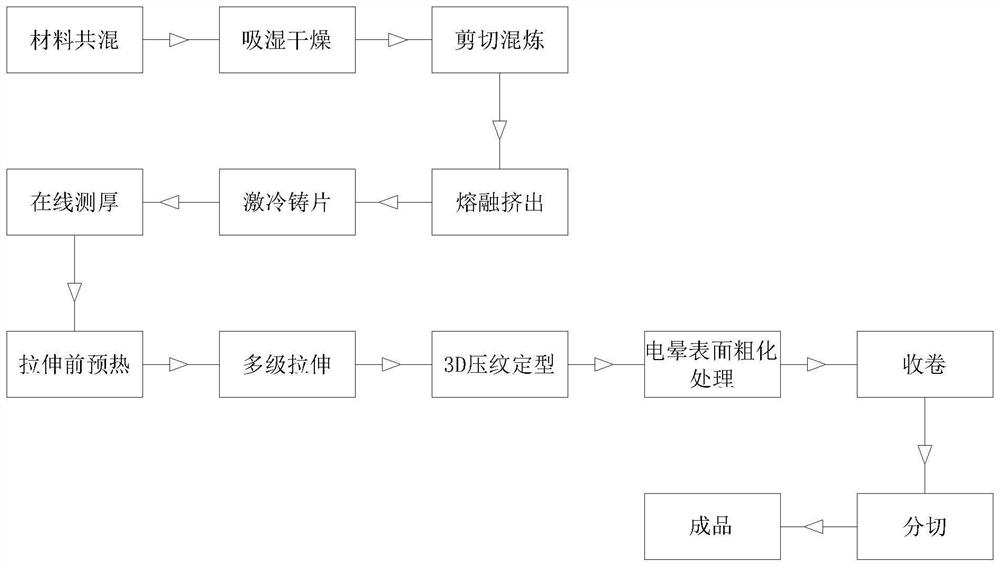

[0032] The invention provides a technical solution: a preparation process of a 3D pattern anti-leakage and high air permeability membrane, the preparation process includes the following steps:

[0033] S1: Material selection: Weigh the raw material components according to the following parts by weight: 20% of air-permeable particles with constant deformation performance, 15% of air-permeable particles with good tensile properties, 20% of high-strength polyethylene, 30% of polyimide resin, 30% epoxy resin, 5% high-strength nano calcium carbonate, 10% puncture-resistant breathable particles and 8% antistatic particles.

[0034] S2: Material blending: Add the selected materials into the vertical mixer and mix them. The rotation speed of the vertical mixer is 310r / min, so that the materials can be fully dissolved and mixed.

[0035] S3: Hygroscopic drying: the blended material is placed inside a vertical dryer for drying.

[0036] S4: Shearing and kneading: After the raw material...

Embodiment 2

[0046] The invention provides a technical solution: a preparation process of a 3D pattern anti-leakage and high air permeability membrane, the preparation process includes the following steps:

[0047] S1: Material selection: Weigh the raw material components according to the following parts by weight: 21% of air-permeable particles with constant deformation performance, 20% of air-permeable particles with good tensile properties, 20% of high-strength polyethylene, 35% of polyimide resin, 35% epoxy resin, 6% high-strength nano calcium carbonate, 13% puncture-resistant air-permeable particles and 10% antistatic particles.

[0048] S2: Material blending: Add the selected materials into the vertical mixer and stir and mix. The rotation speed of the vertical mixer is 315r / min, so that the materials can be fully dissolved and mixed.

[0049] S3: Hygroscopic drying: the blended material is placed inside a vertical dryer for drying.

[0050] S4: Shearing and kneading: After the raw ...

Embodiment 3

[0060] The invention provides a technical solution: a preparation process of a 3D pattern anti-leakage and high air permeability membrane, the preparation process includes the following steps:

[0061] S1: Material selection: Weigh the raw material components according to the following parts by weight: 23% of air-permeable particles with constant deformation performance, 20% of air-permeable particles with good tensile properties, 37% of high-strength polyethylene, 37% of polyimide resin, 32% epoxy resin, 8% high-strength nano calcium carbonate, 13% puncture-resistant air-permeable particles and 10% antistatic particles.

[0062] S2: Material blending: Add the selected materials into the vertical mixer and mix them. The rotation speed of the vertical mixer is 320r / min, so that the materials can be fully dissolved and mixed.

[0063] S3: Hygroscopic drying: the blended material is placed inside a vertical dryer for drying.

[0064] S4: Shearing and kneading: After the raw mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com