Functional film for preventing ammonia gas from escaping in composting process and preparation method of functional film

A functional film and composting technology, applied in botany equipment and methods, organic fertilizer equipment, chemical instruments and methods, etc., can solve the problems of limited barrier effect and no secondary barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

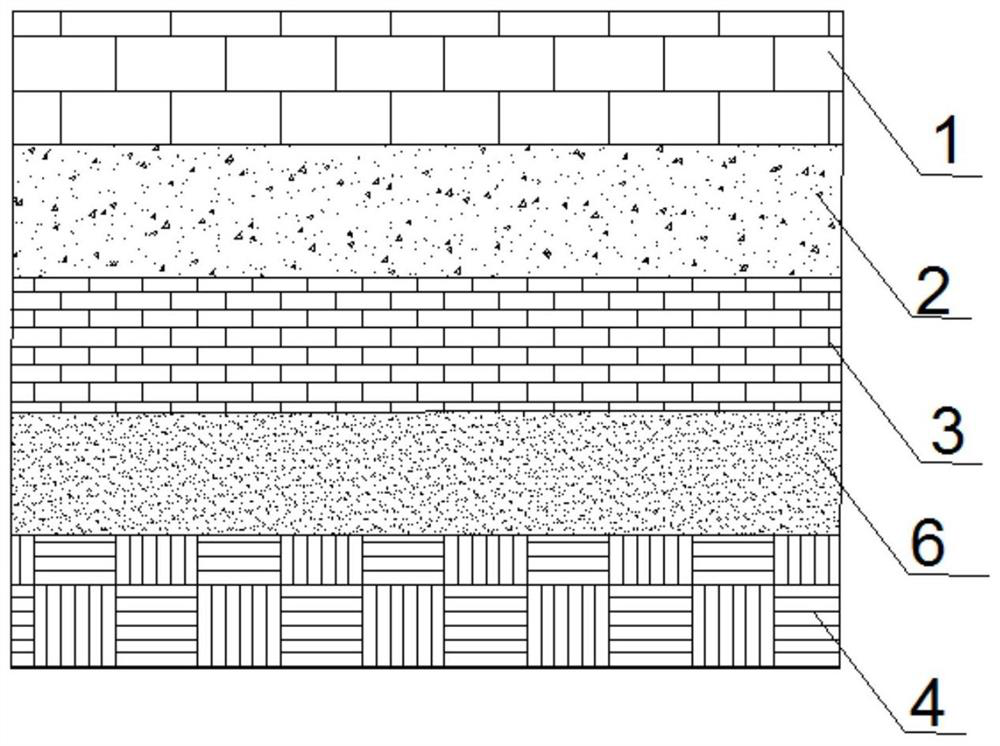

[0029] Example 1, such as figure 1 Shown:

[0030] A method for preparing a functional film that blocks ammonia gas escape during composting, using a hot-melt device to melt polyester fiber Oxford cloth 1, polyurethane hot-melt adhesive 2, expanded polytetrafluoroethylene film 3, and polyvinyl alcohol environmental protection adhesive 6 and activated carbon non-woven fabric 4 are compounded and molded at 130 degrees Celsius through a gluing and hot-pressing composite process, matured and cured, and then packaged to obtain a finished product.

[0031] The polyurethane hot-melt adhesive 2 and the polyvinyl alcohol environmental protection adhesive 10 in the above-mentioned specific embodiment 1 adopt the method of integral cloth surface coating.

Embodiment 2

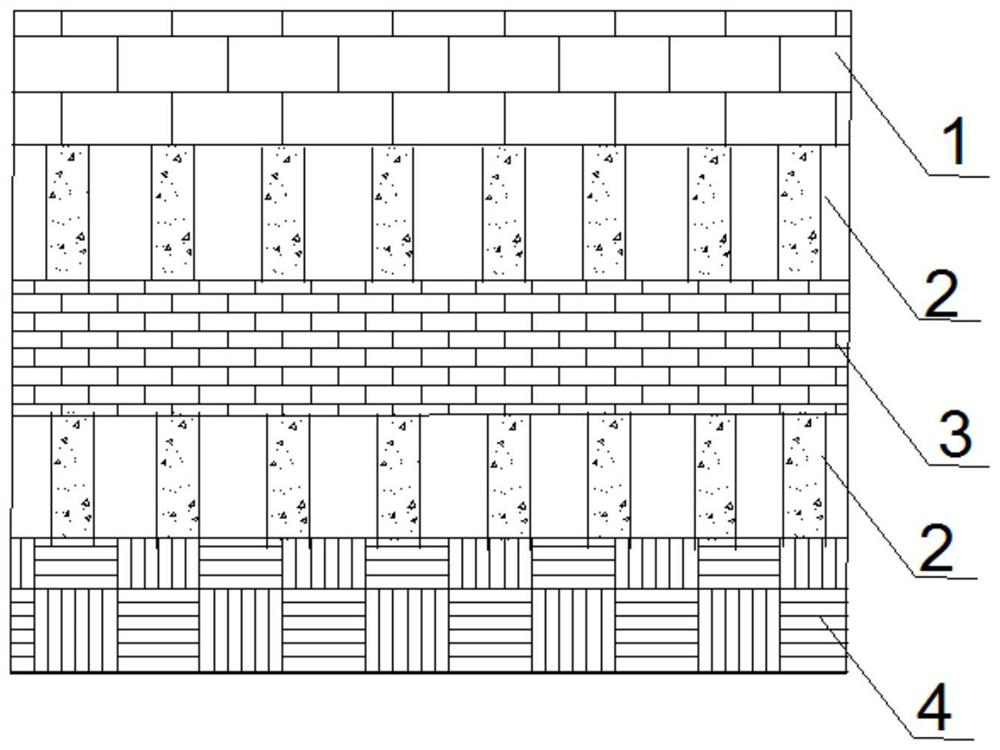

[0032] Example 2, such as figure 2 Shown:

[0033] A preparation method of a functional film for blocking the escape of ammonia gas in the composting process, using a hot-melt device to mix polyester fiber Oxford cloth 1, polyurethane hot-melt adhesive 2, expanded polytetrafluoroethylene film 3, polyurethane hot-melt adhesive 2 and Activated carbon non-woven fabric 4 is compounded and formed at 140 degrees Celsius through a gluing and hot-pressing composite process, matured and cured, and packaged to obtain a finished product.

[0034] The polyurethane hot-melt adhesive 2 in the above-mentioned specific embodiment 2 adopts the method of dispensing at equal intervals.

Embodiment 3

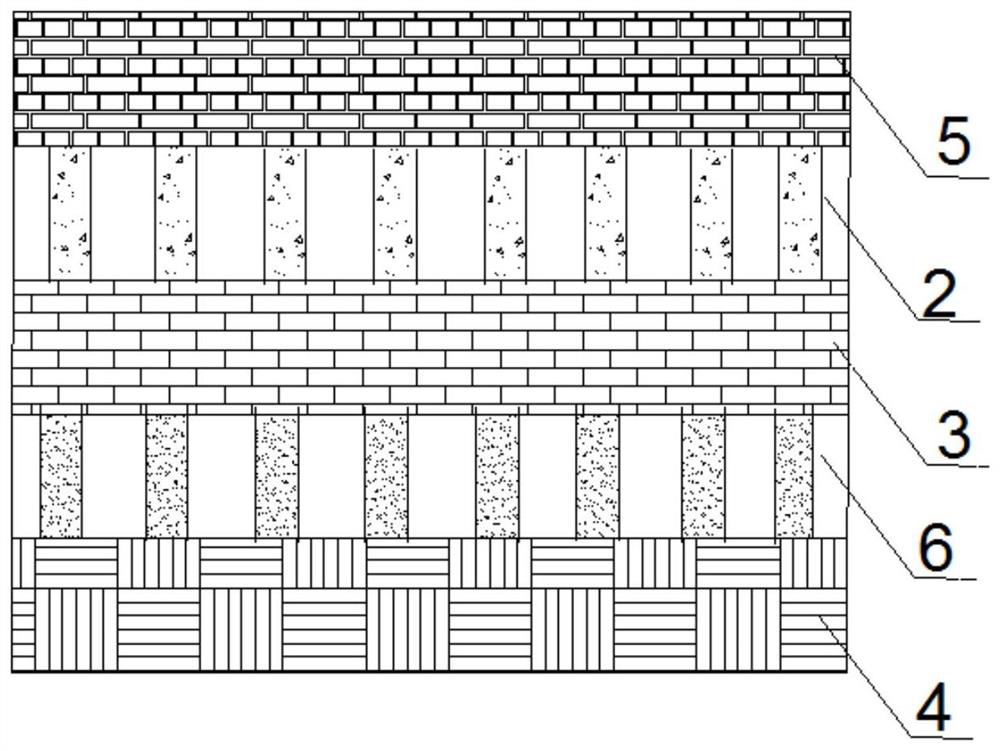

[0035] Example 3, such as image 3 Shown:

[0036] A method for preparing a functional film that blocks the escape of ammonia gas during the composting process, using a hot-melt device to combine non-woven fabric 5, polyurethane hot-melt adhesive 2, expanded polytetrafluoroethylene film 3, polyvinyl alcohol environmental protection adhesive 6 and activated carbon The non-woven fabric 4 is compounded and molded at 130 degrees Celsius through the gluing and hot-pressing composite process, matured and cured, and packaged to obtain a finished product.

[0037] The polyurethane hot-melt adhesive 2 and the polyvinyl alcohol environmental protection adhesive 10 in the above-mentioned specific embodiment 3 adopt the method of dispensing at intervals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com