Antibacterial anti-mite sponge and preparation method thereof

A sponge and anti-mite technology, applied in the field of sponges, can solve the problem that sponge products are easy to breed bacteria and mites, and achieve the effects of inhibiting the growth of bacteria, blocking the food chain of mites, and having a soft feel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

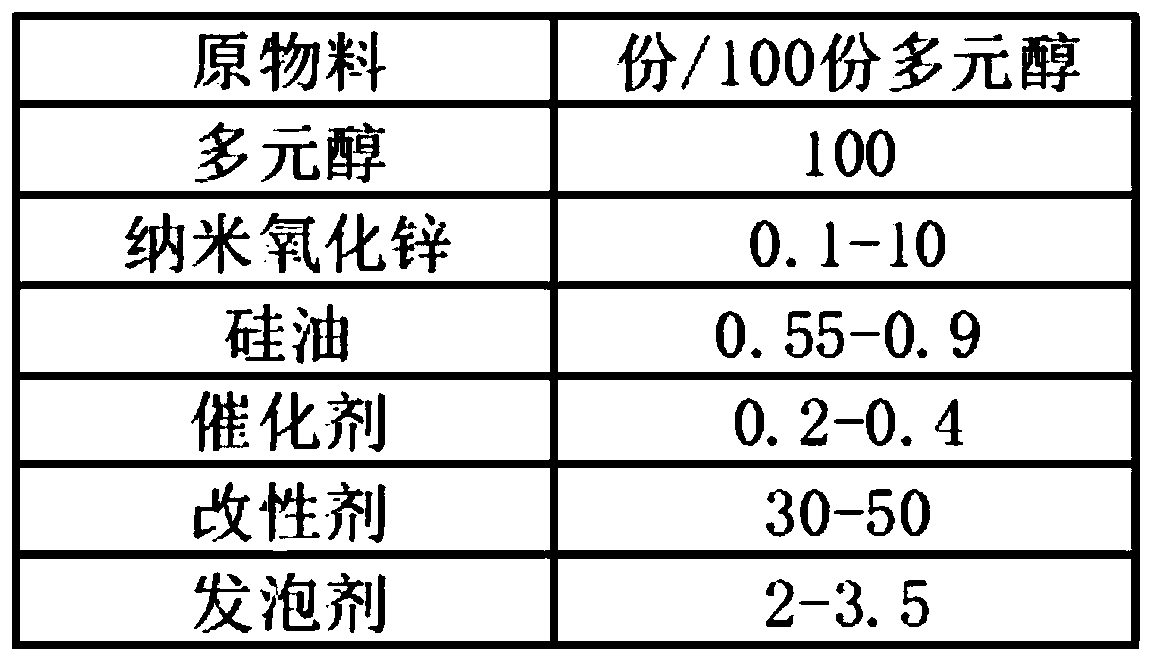

[0029] An antibacterial and anti-mite sponge is produced by foaming the mixture of the following parts by mass:

[0030] Nano-zinc oxide: 0.5 parts, which is nano-silver oxide with a particle size between 1 and 100 nanometers;

[0031] Polyol: including 90 parts of PPG and 10 parts of POP, its hydroxyl value is 57mgKOH / g;

[0032] Silicone oil: including 0.27 parts of epoxy-modified silicone oil and 0.38 parts of amino-modified silicone oil;

[0033] Catalyst: including 0.23 parts of polyurethane gel catalyst A33 and 0.12 parts of polyurethane organotin catalyst T-9;

[0034] Foaming agent: 2.5 parts of water;

[0035] Modifier: 34.1 parts of TDI80.

Embodiment 2

[0037] An antibacterial and anti-mite sponge is produced by foaming the mixture of the following parts by mass:

[0038] Nano-zinc oxide: 1.5 parts, which is nano-silver oxide with a particle size between 1 and 100 nanometers;

[0039] Polyol: 100 parts of 330N, its hydroxyl value is 59mgKOH / g;

[0040] Silicone oil: including 0.47 parts of epoxy-modified silicone oil and 0.33 parts of amino-modified silicone oil;

[0041] Catalyst: 0.3 parts polyurethane gel catalyst A33;

[0042] Surfactant: 0.06 parts of cationic surfactant A1;

[0043] Foaming agent: 3 parts of water;

[0044] Modifier: 48 parts of modified MDI.

Embodiment 3

[0046] An antibacterial and anti-mite sponge is produced by foaming the mixture of the following parts by mass:

[0047] Nano-zinc oxide: 1.8 parts, which is nano-silver oxide with a particle size between 1 and 100 nanometers;

[0048] Polyol: including 87 parts of 330N and 13 parts of POP, its hydroxyl value is 61mgKOH / g;

[0049] Silicone oil: including 0.43 parts of epoxy-modified silicone oil and 0.43 parts of amino-modified silicone oil;

[0050] Catalyst: 0.33 parts of polyurethane gel catalyst A33;

[0051] Foaming agent: 2.6 parts of water;

[0052] Modifier: 37.2 parts of TDI80.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com