Method for producing double-sided ultrafine supersoft floss fabric

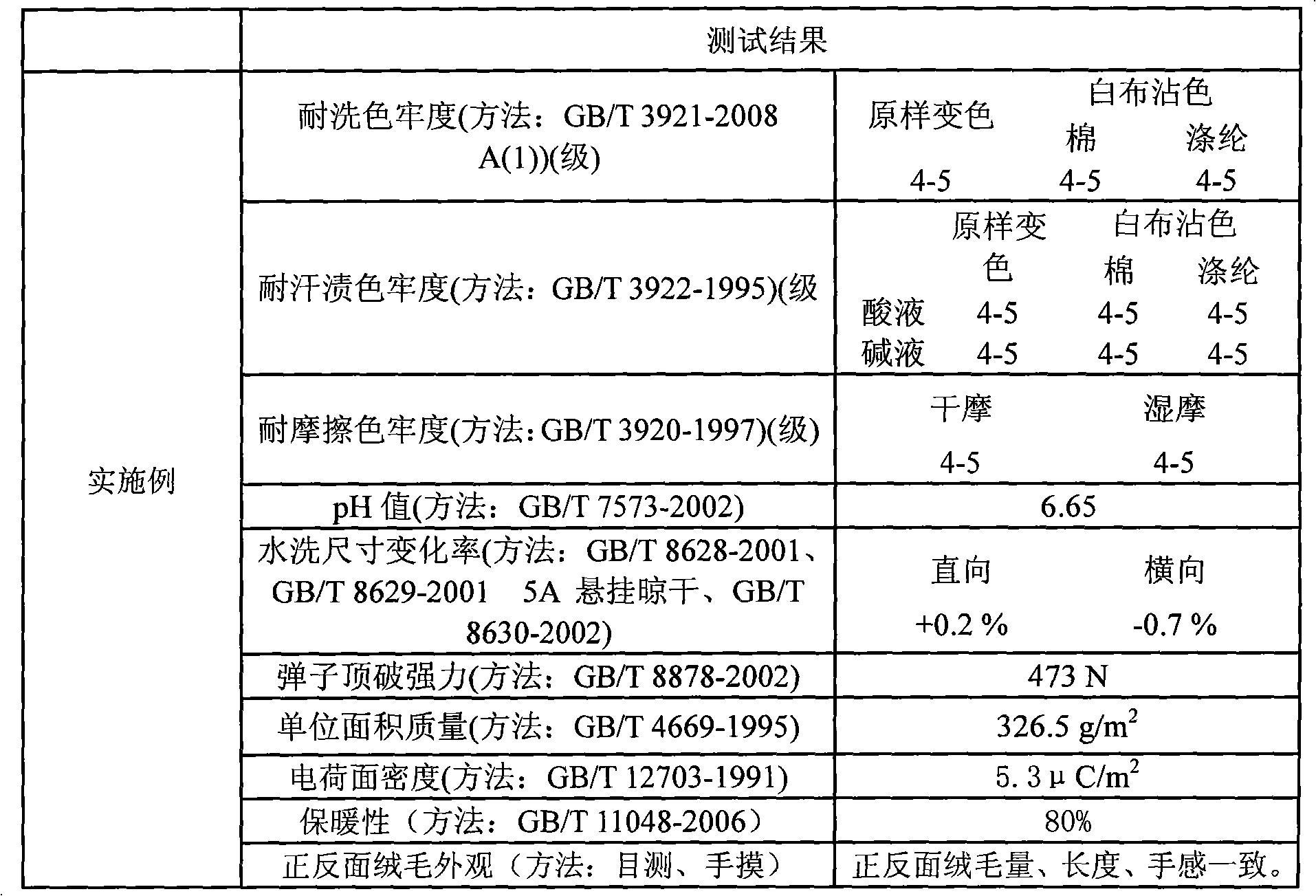

A production method and technology of double-faced fleece, which is applied in home textiles and clothing fields, can solve problems such as poor hand feeling, affecting performance, and scarce fluff, and achieve the effects of excellent color fastness, expanded use occasions, and strong anti-static machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

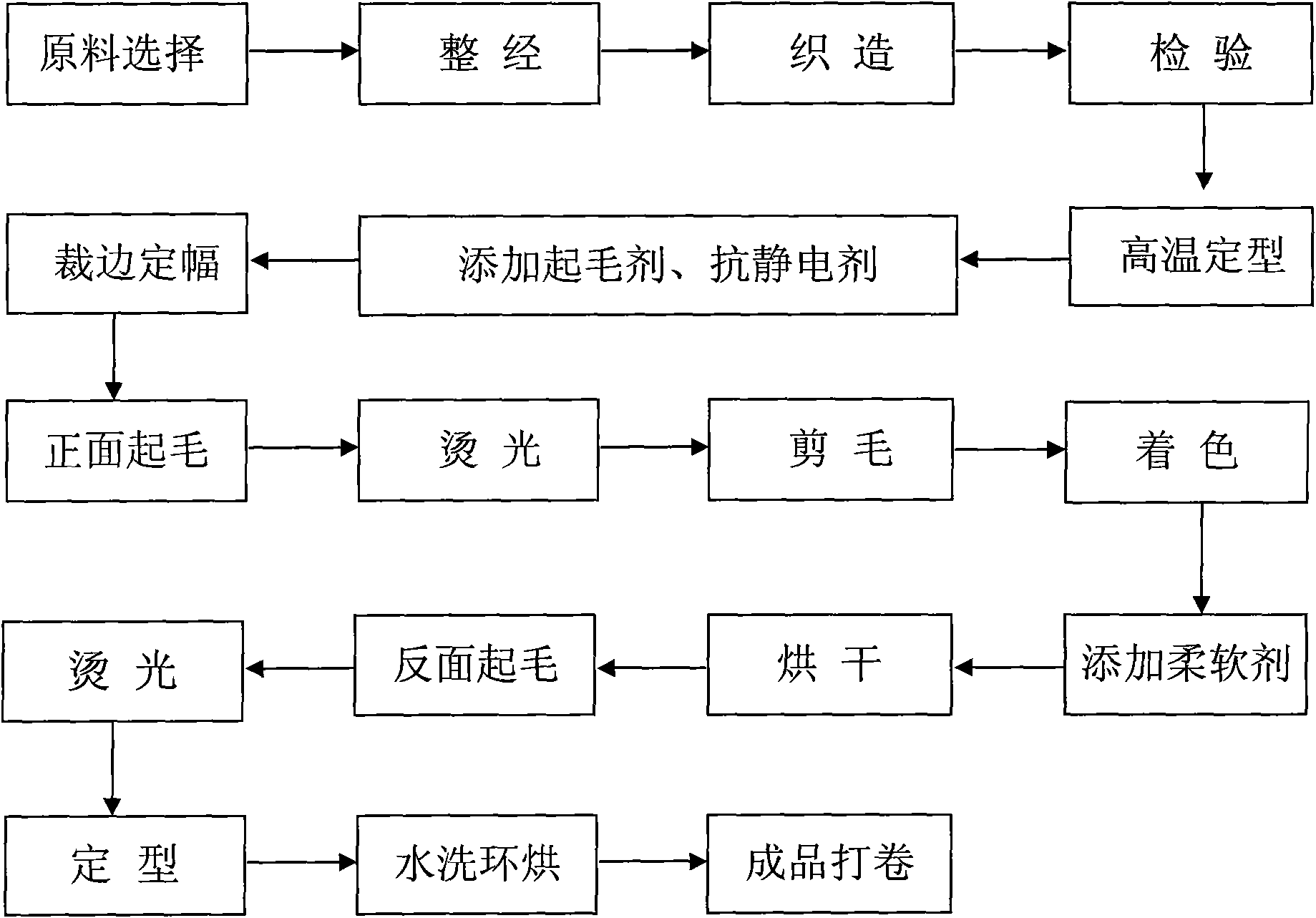

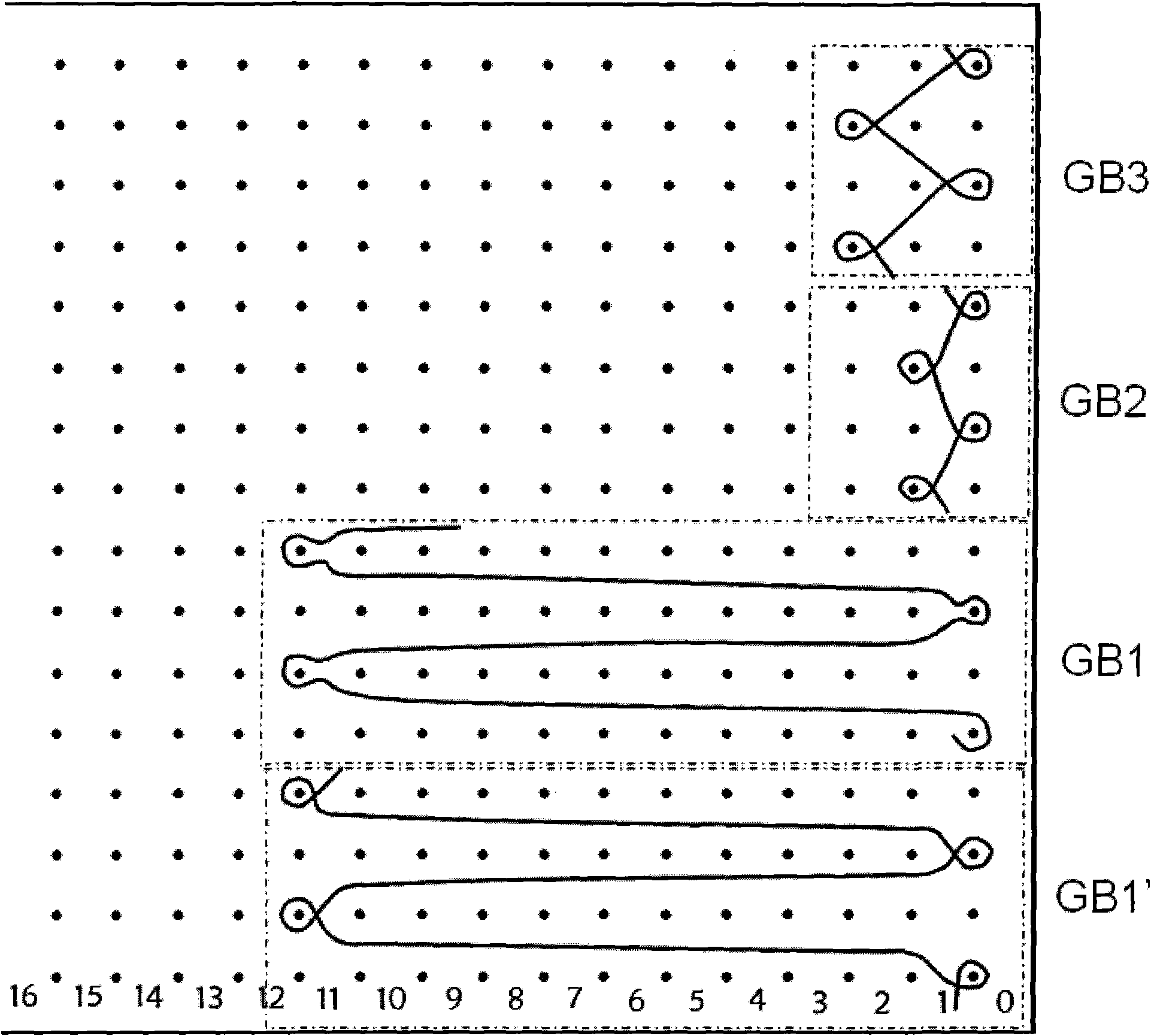

[0018] refer to figure 1 , the production method of this superfine supersoft double-faced fleece fabric, the steps are as follows: (1) raw material selection, 2) warping, (3) weaving, (4) inspection, (5) high temperature setting, (6) adding fluff agent, antistatic agent, (7) drying, (8) front fluffing, (9) scalding, (10) shearing, (11) coloring, (12) adding softener, (13) drying, (14) Raising the reverse side, (15) scalding, (16) high-temperature setting, (17) washing and ring drying, so that the product has the same effect as the front and back suede; (18) the finished product is rolled; the weaving process is K / S warp knitting three-bar weaving process, the organizational structure adopted is 23 / 10 for GB3, 10 / 12 for GB2, and 16, 15 / 01, 15, 14 / 01, 14, 13 / 01, 13, 12 for GB1 / 01, 12, 11 / 01, 11, 10 / 01, 10, 9 / 01, 9, 8 / 01, 8, 7 / 01, 7, 6 / 01, 6, 5 / 01, 5, 4 / 01 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com