Dust free chalk and preparation process thereof

A chalk and talc technology, applied in pencil leads, household appliances, applications, etc., can solve the problems of dust pollution, unhealthy users, easy powder falling when writing and wiping, and achieve the effect of not easy powder falling and good bonding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiment adopts optimal proportioning (weight ratio) to be:

[0015] Titanium dioxide 15%

[0016] Talc 35%

[0017] Water-soluble wax 15%

[0018] Glycerin 5%

[0019] water 30%

[0020] Process description:

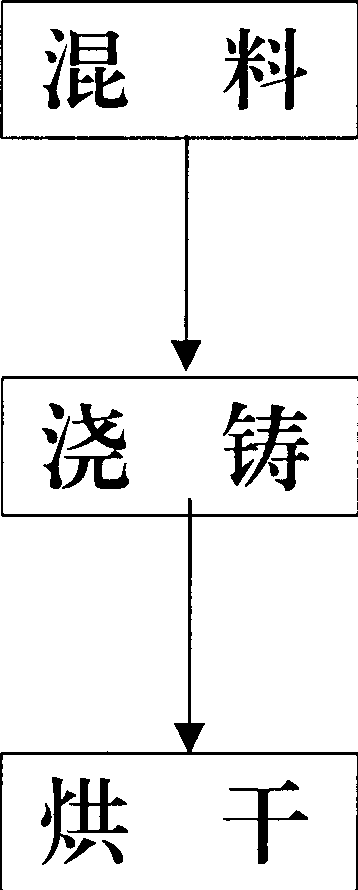

[0021] 1. Mixing: Mix titanium dioxide and talcum powder, add water-soluble wax, glycerin, and water and stir well to make a paste.

[0022] 2. Casting: Fill the paste into the mold, take it out after compaction, and fully dry it.

[0023] 3. Drying: Put the semi-finished product in the oven after drying, bake at 120°C for 1-2 hours, take it out and cool it naturally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com