Preparing method of fluororubber/nanofiller composite material

A nano-filler and composite material technology is applied in the preparation of fluororubber/nano-filler composite materials and the field of fluororubber. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

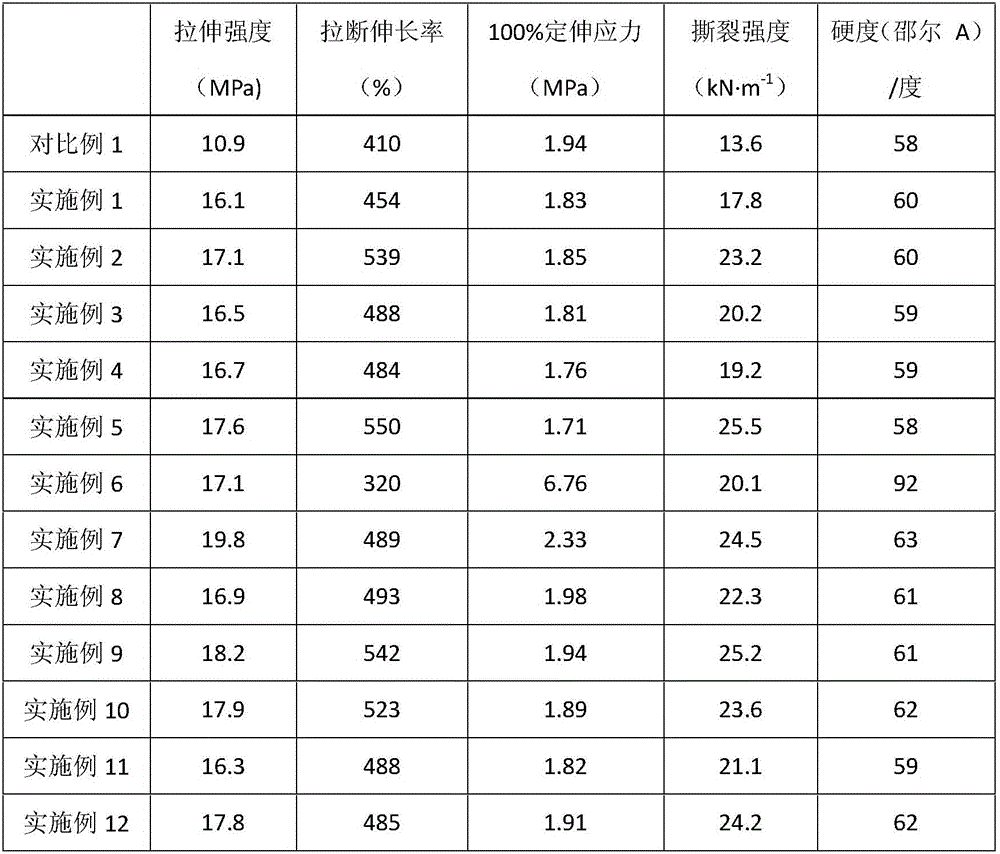

Examples

Embodiment 1

[0034] In terms of mass percentage, the consumption of each raw material is as follows:

[0035] Viton 95%

[0036] Montmorillonite 2% (montmorillonite: deionized water = 1:20)

[0038] Triallyl Isocyanurate 1%

[0039] Dicumyl peroxide 1%

[0040] First add montmorillonite to deionized water (the mass ratio of montmorillonite to deionized water is 1:20), mechanically stir for 60min, and the speed is 3000r min -1 , ultrasonic dispersion for 30min, power 1500w, to obtain montmorillonite hydrosol.

[0041] The fluororubber raw rubber was masticated with a rubber internal mixer at a temperature of 50 °C and a rotor speed of 40 r min -1 , masticating for 3min, set the temperature of the rubber internal mixer to 120°C, and the rotor speed to 40r·min -1 , slowly drop the montmorillonite hydrosol for 15 minutes. During this process, a large amount of water vapor appears at the top bolt. After the montmorillonite hydrosol is added, lower the top bolt and con...

Embodiment 2

[0044] In terms of mass percentage, the consumption of each raw material is as follows:

[0045] Viton 88%

[0046] Montmorillonite 2% (montmorillonite: deionized water = 1:20)

[0047] Sodium dodecylbenzenesulfonate (SDBS) 1%

[0049] Triallyl isocyanurate 3%

[0050] Dicumyl peroxide 1%

[0051] First add montmorillonite to deionized water (the mass ratio of montmorillonite to deionized water is 1:20), then add surfactant sodium dodecylbenzene sulfonate (SDBS), stir mechanically for 60min, and rotate at a speed of 3000r min -1 , ultrasonic dispersion for 30min, power 1500w, to obtain montmorillonite pre-dispersion.

[0052] The fluororubber raw rubber was masticated with a rubber mixer at a temperature of 50 °C and a rotor speed of 40 r min -1 , masticating for 3min, set the temperature of the rubber internal mixer to 120°C, and the rotor speed to 40r·min -1 , slowly drop the montmorillonite pre-dispersion solution for 15 minutes. At this time, ...

Embodiment 3

[0055] In terms of mass percentage, the consumption of each raw material is as follows:

[0056] Viton 88%

[0057] Montmorillonite 2% (montmorillonite: deionized water = 1:20)

[0058] Cetyltrimethylammonium bromide (CTAB) 1%

[0060] Triallyl isocyanurate 3%

[0061] Dicumyl peroxide 1%

[0062] First add montmorillonite to deionized water (the mass ratio of montmorillonite to deionized water is 1:20), then add surfactant cetyltrimethylammonium bromide (CTAB), mechanically stir for 60min, 3000r·min -1 , ultrasonic dispersion for 30min, power 1500w, to obtain montmorillonite pre-dispersion.

[0063] The fluororubber raw rubber was masticated with a rubber mixer at a temperature of 50 °C and a rotor speed of 40 r min -1 , masticating for 3min, set the temperature of the rubber internal mixer to 120°C, and the rotor speed to 40r·min -1 , slowly drop the montmorillonite pre-dispersion, the dropping time is 15min, a large amount of water vapor appea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com