Method for purifying granular slag steel

A purification method and technology of slag steel, applied in the field of purification, can solve the problems of large particle size difference of slag steel, large floor space, increased energy consumption, etc., and achieve the effect of no dust flying, small floor space and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

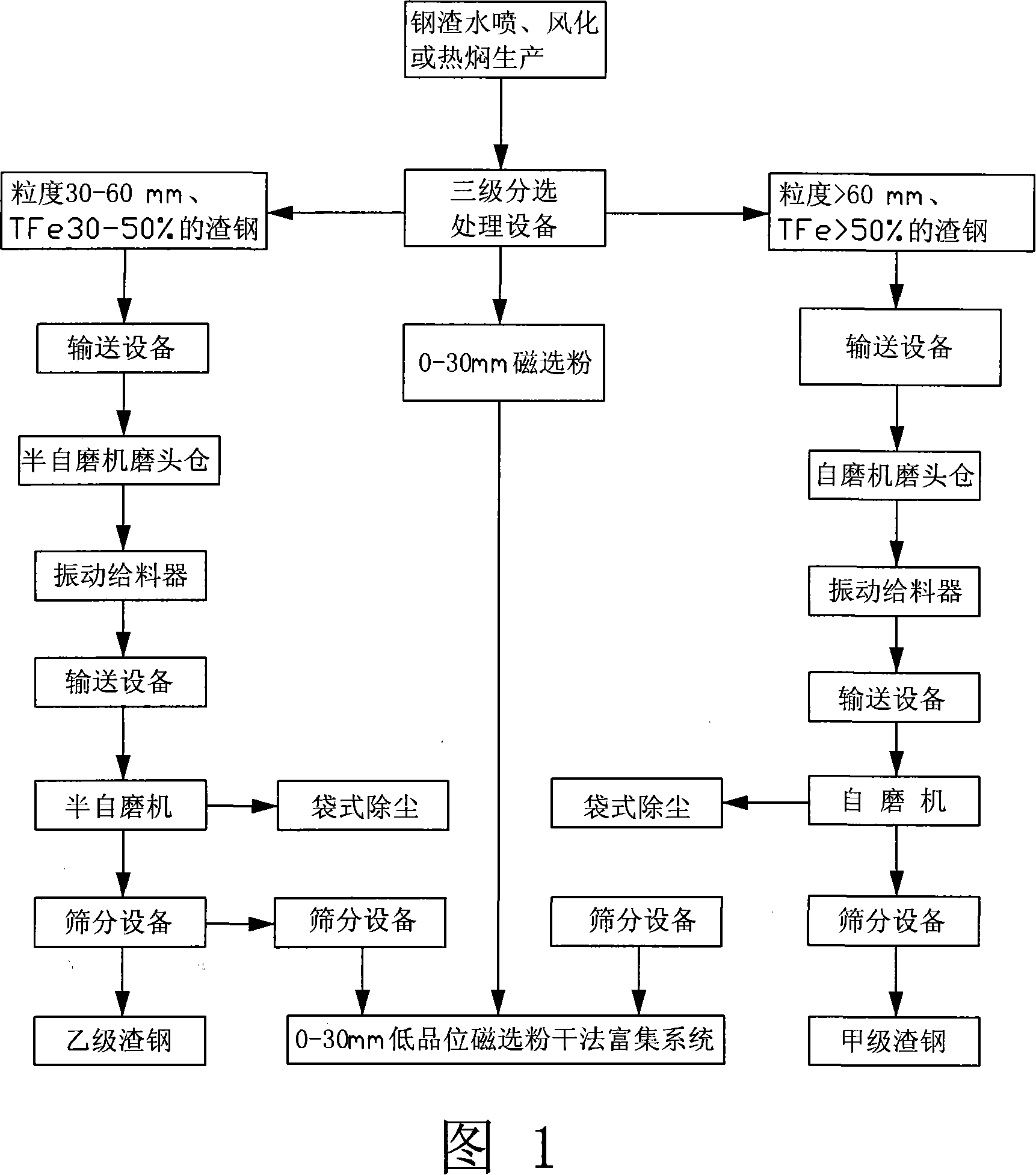

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0019] See Fig. 1, a method for purifying granular slag steel. After weathering and thermal braising, larger granular steel slag with a particle size of 30-60mm and TFe of 30-50% and large granular slag with a particle size of > 60mm and TFe > 50% Steel raw materials are sent to the grinding head warehouse of the semi-autogenous mill and the grinding head warehouse of the autogenous mill with belt conveyors, plate conveyors and other conveying equipment; the large-grained slag steel with a particle size > 60mm and TFe > 50% is passed through rods. The sieve, vibrating feeder, and transportation equipment are evenly and stably fed into the autogenous mill for continuous grinding. During the grinding process, the coarse particles collide and rub against each other, and the non-magnetic slag and small-grain steel attached to the surface are separated from t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com