Large vacuum furnace for processing arsenic-containing gold ore or arsenic concentrate and continuous operation method thereof

A vacuum furnace and gold mine technology, applied in the field of large-scale vacuum furnace and its continuous operation, can solve the problems of not being popularized widely and the lack of large-scale chemical industry production equipment, etc., and achieve the effect of low operating cost, fewer operators and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

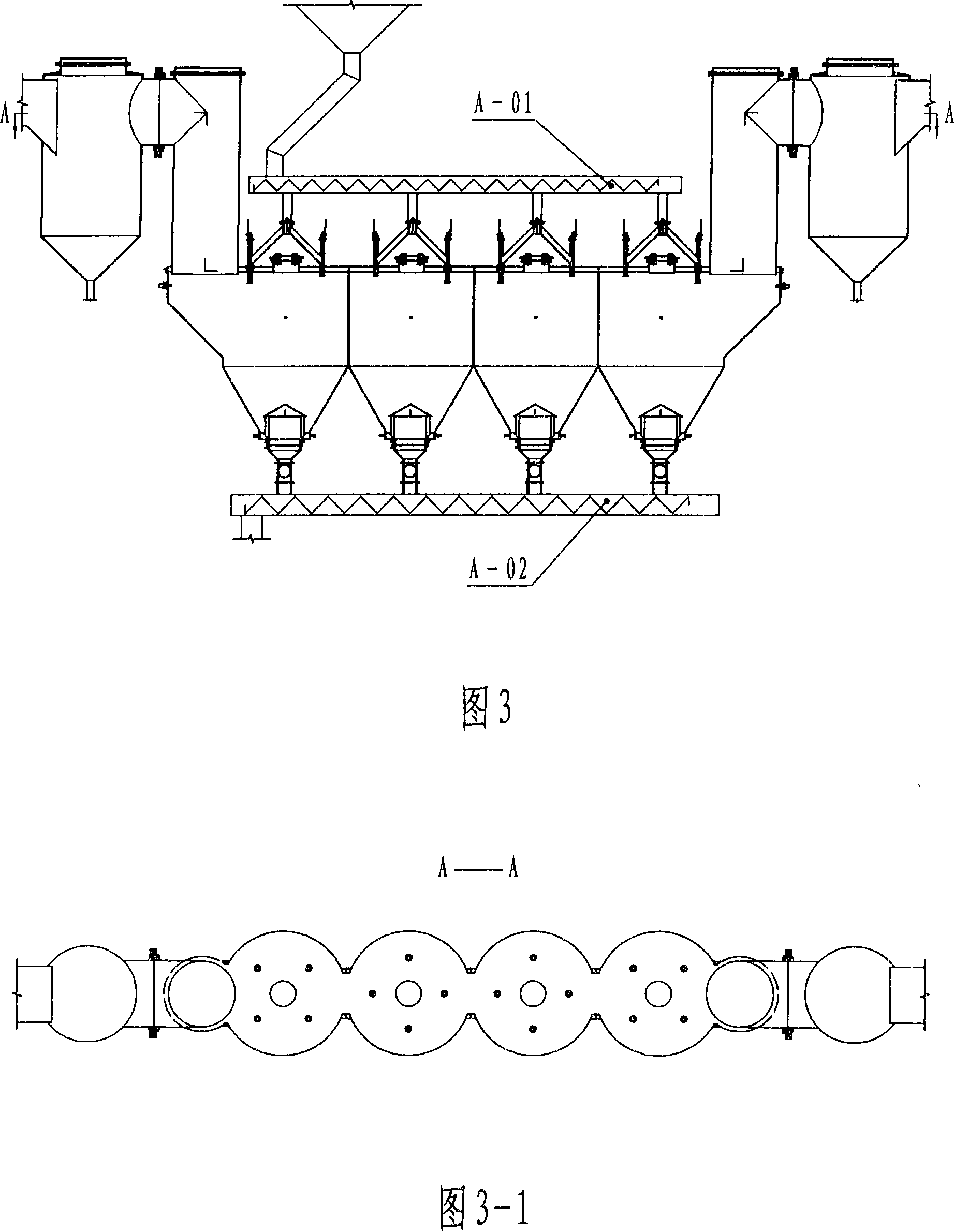

[0062] The test design of this embodiment is a fully automatic continuous operation vacuum furnace with a diameter of 3.2 meters, which can process 600 tons of arsenic-containing gold ore per day.

[0063] The process and operating conditions of the fully automatic continuous operation vacuum furnace for processing arsenic-containing gold ore are as follows:

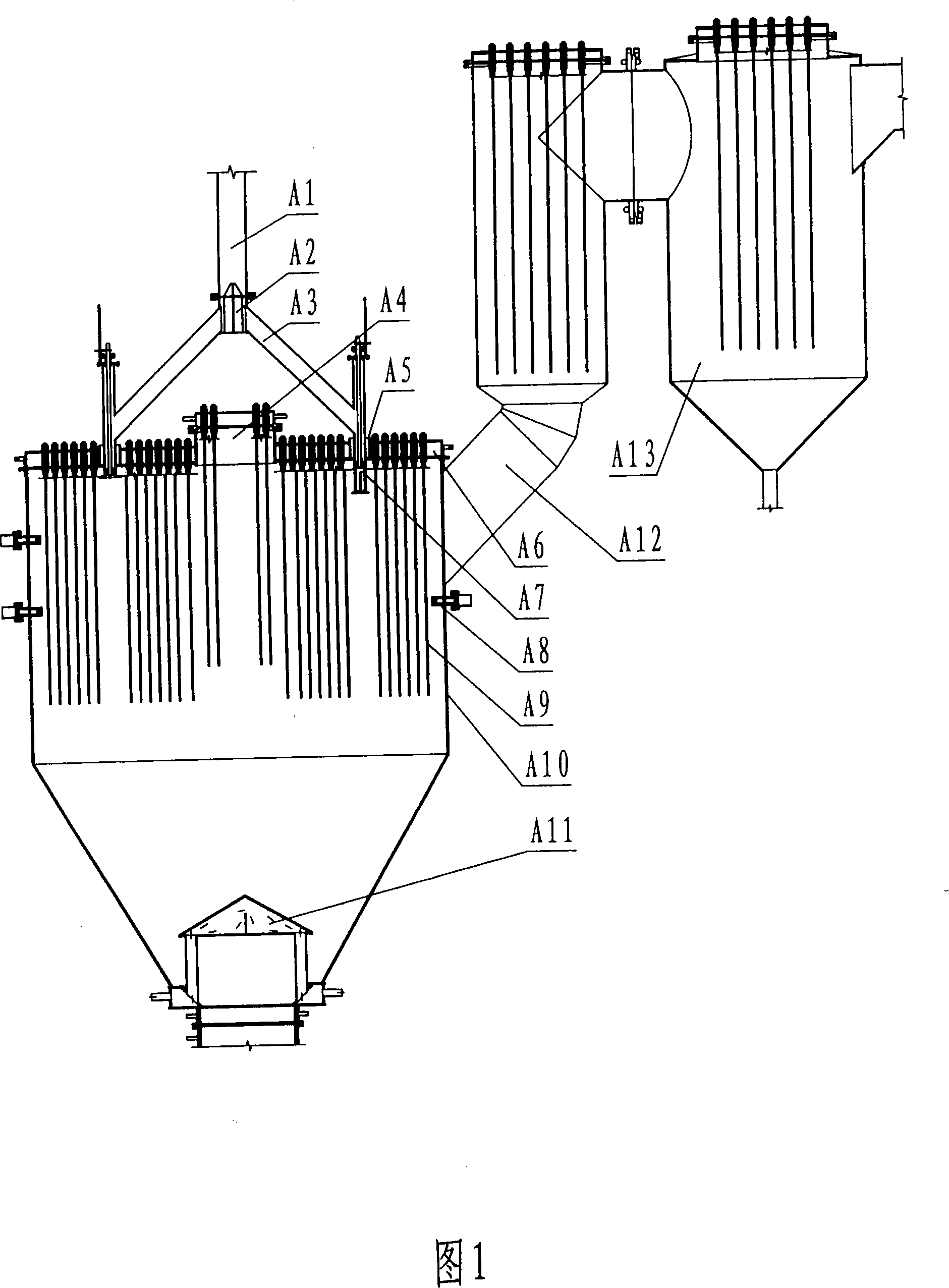

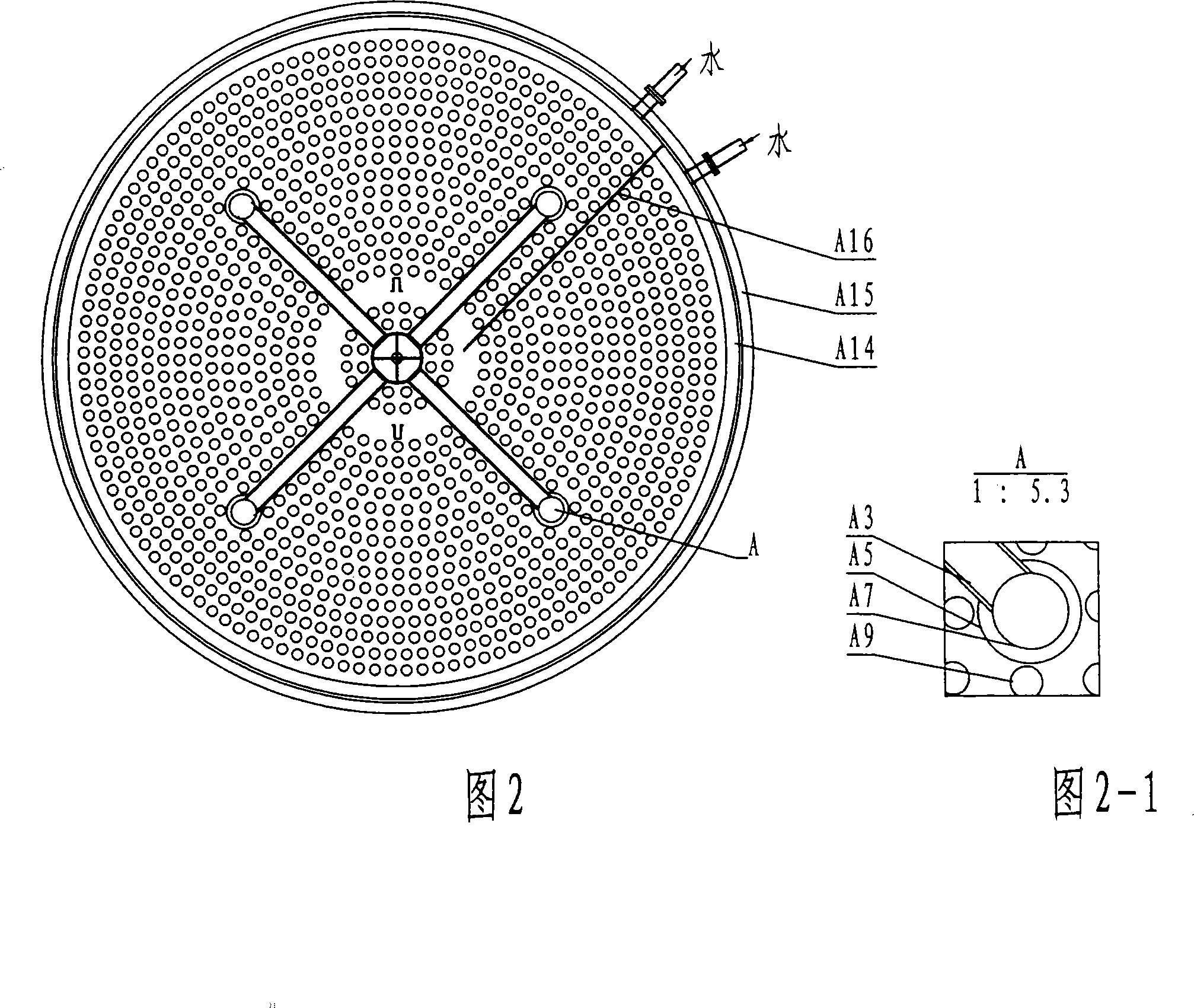

[0064] Referring to Fig. 11, a general device diagram of a large-scale vacuum furnace for processing arsenic-containing gold ore or arsenic concentrate and its fully automatic continuous operation method according to the present invention. Divided by the dotted line, there are six major areas: area A of the vacuum furnace body, area B of the automatic control device for concentrate conveying, area C of the material level photoelectric controller, area D of the water-cooled spiral slag discharger, area E of the product collection device, and area F of the tail gas treatment system. It is composed of parts, taking the area...

Embodiment 2

[0074] A fully automatic continuous operation vacuum furnace with a diameter of 1.2 meters was designed for the test, with a daily processing capacity of 50 tons of arsenic concentrate.

[0075] The equipment used in this embodiment and the process conditions for processing the arsenic concentrate are the same as in Embodiment 1.

Embodiment 3

[0077] In this embodiment, a vacuum furnace with a diameter of 2.1 meters is designed for discontinuous operation for processing arsenic concentrate, and each furnace is loaded with 8 to 15 tons of ore. The anti-corrosion measures, sealing structure and installation method of the electric heating tube used, the water-cooled screw machine, and the method for collecting products by the condensing drum are all the same as in Embodiment 1, the difference is that it is intermittent operation and there is no automatic control system. The vacuum smelting process conditions of this embodiment are: the vacuum distillation temperature is 700-850° C., the residual pressure of the vacuum system is 13.332 Pa-93324 Pa, and the distillation time can be stopped when the residue contains less than 0.5% arsenic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com