Metal surface scratch detection method and device

A metal surface and detection method technology, applied in the field of image processing, can solve the problems of not being able to find in time, unable to meet the requirements of industrial scratch defect detection, prone to misjudgment, etc., to achieve intelligent automatic control, simplify machine vision algorithms, The effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

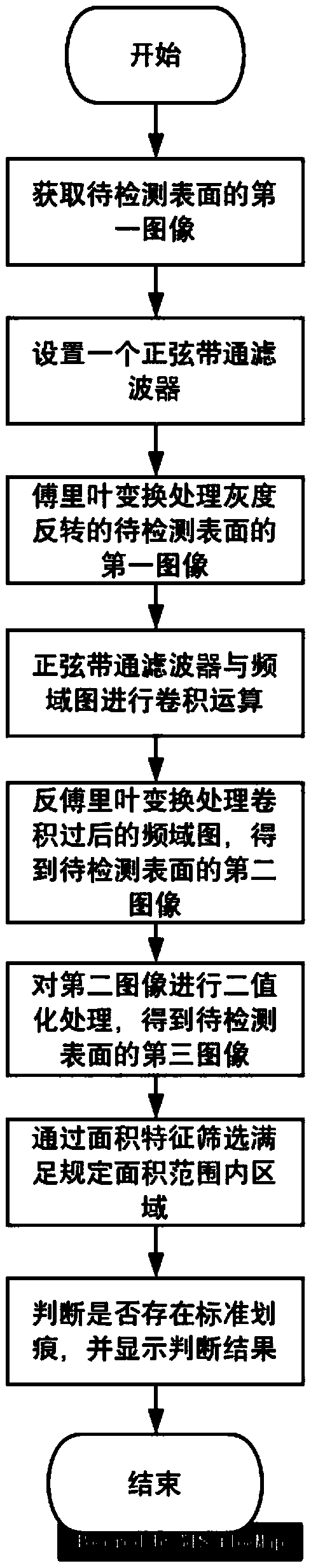

[0014] Example: such as figure 1 Shown, a kind of metal surface scratch detection method comprises the following steps:

[0015] Step 101: Acquiring a first image of the surface to be detected;

[0016] The terminal can call the camera software interface to take pictures of the object to be inspected with a preset resolution and preset gray level, and obtain the first image of the surface to be inspected. Among them, the object to be detected can be a general steel surface, or a steel surface with a certain texture;

[0017] Among them, the terminal can preset its resolution and gray level according to the model of the camera, the type of light source, the size of the field of view, and the size of the recognition accuracy. When the camera captures the first image of the surface of the object to be detected with a preset resolution and gray level, the terminal can further process the received digital signal.

[0018] Step 102: setting a sinusoidal bandpass filter;

[0019]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com