Peony stiff twig cut flower production method

A production method and technology of peony, applied in the field of plant cultivation, can solve the problems of manpower and material resources, cut flower harvesting, inconvenient preservation and use, and not being brought into play, so as to extend the length of cut flower branches, good cold storage effect and water absorption capacity strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 method of the present invention produces peony cut flower

[0042] From 2010 to 2012, robust adult plants of the 'Oolong Pengsheng' peony (P.suffruticosa Zhongyuan Group 'Wu Long Peng Sheng') planted in the open field were selected as test materials to implement the scheme of the present invention.

[0043] peony plant preparation

[0044] Plant peony seedlings in the autumn of 2009. Before planting, select the land according to the ecological habits of peony, apply sufficient base fertilizer, and carefully prepare the site; when planting, dig planting holes according to the row spacing of 80cm×80cm, the hole opening is 20cm×20cm, and the depth is 40-45cm. Put the seedlings or grafted seedlings in the hole, make the root system evenly distributed, fill the soil and compact it. Seedlings were raised for one year, and 30 robust peony plants were selected in the autumn of 2010, and 15 plants were used as a group to start the experiment.

[0045] (1) Cut flow...

Embodiment 2

[0065] The comparison of embodiment 2 hard branches cut flowers of the present invention and traditional soft branches cut flowers

[0066] The cut peony flowers harvested in this embodiment are the cut peony flowers harvested in the spring flowering period of 2012 in the first group and the second group of 30 peony plants in Example 1.

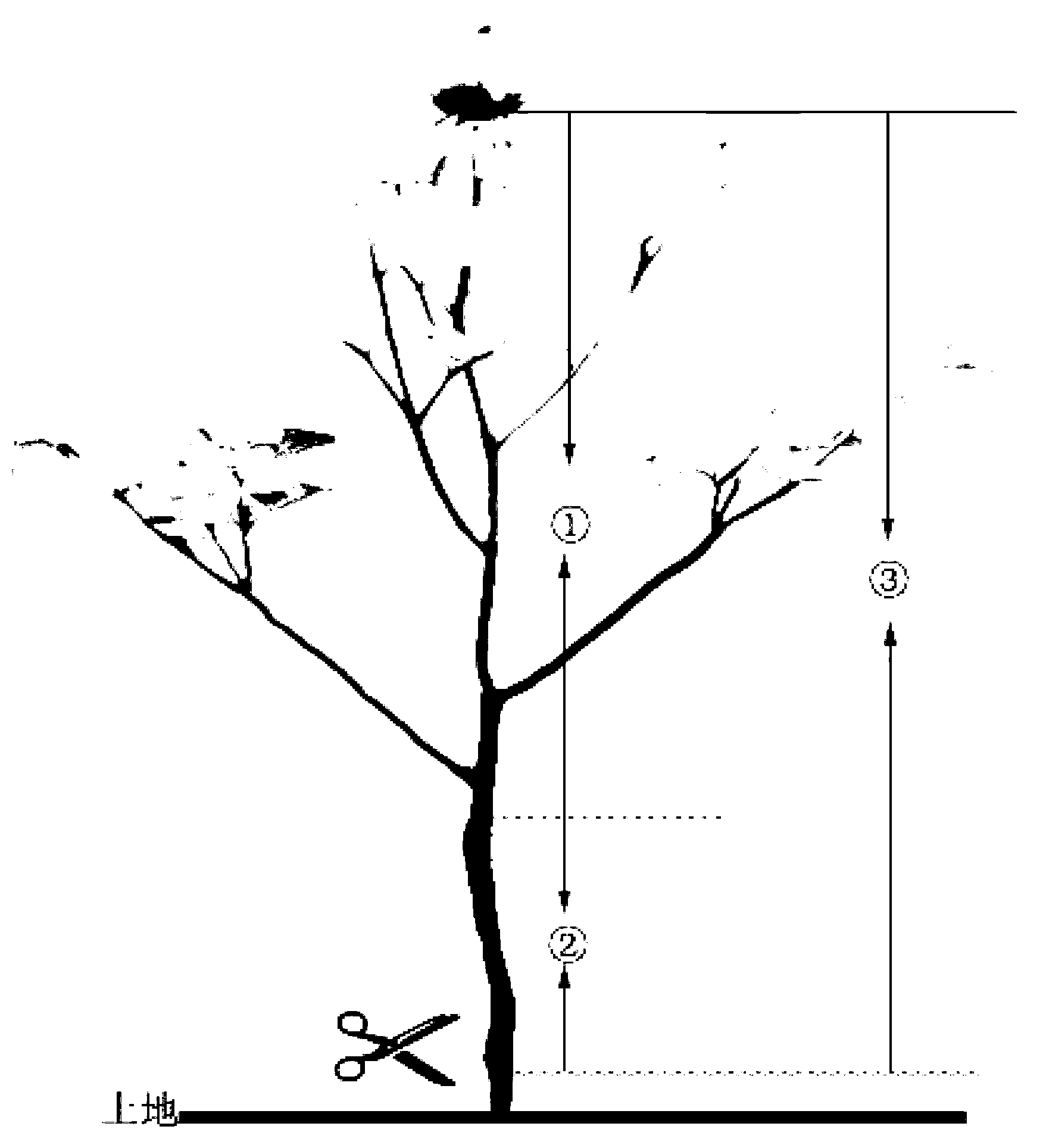

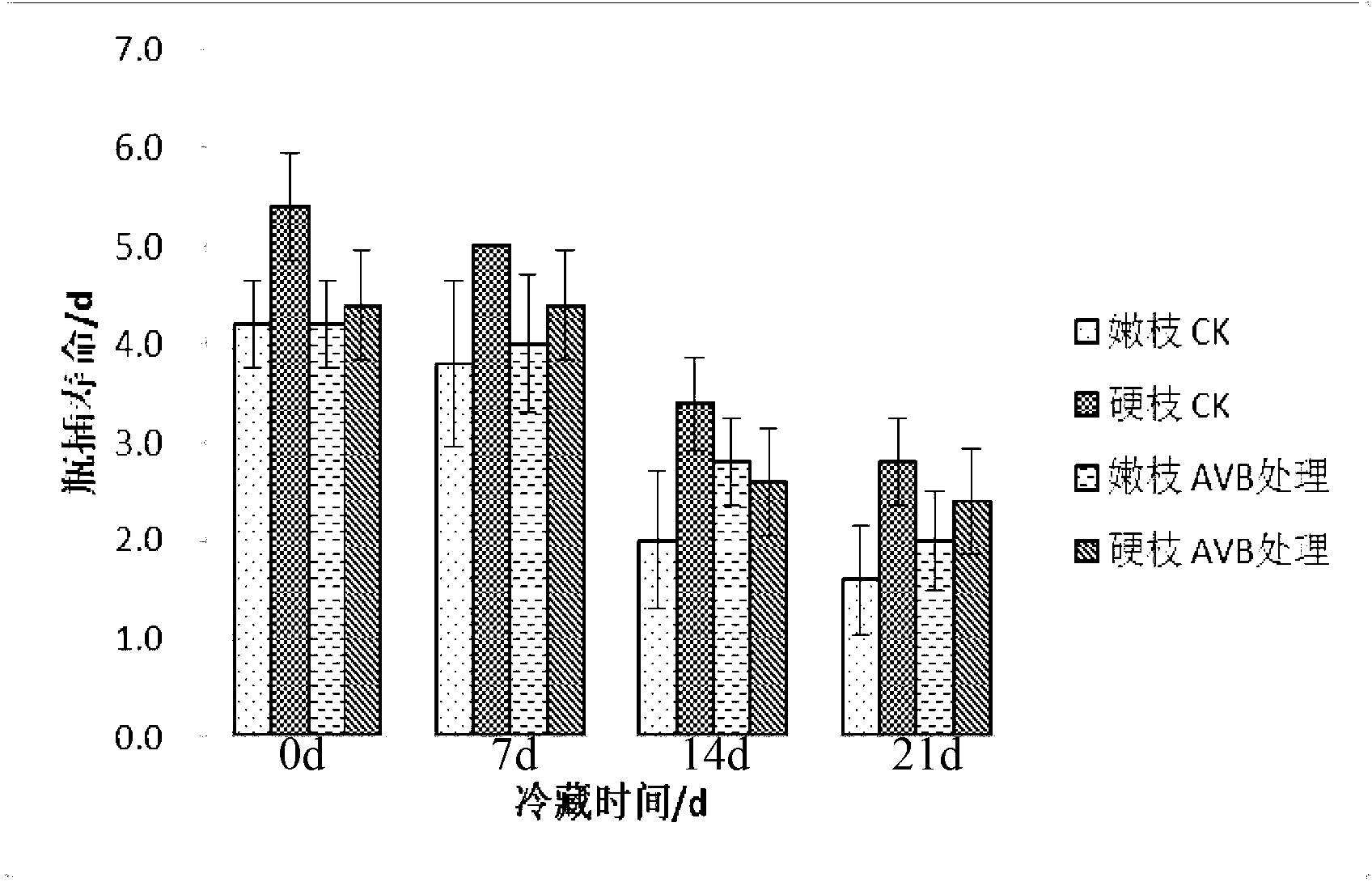

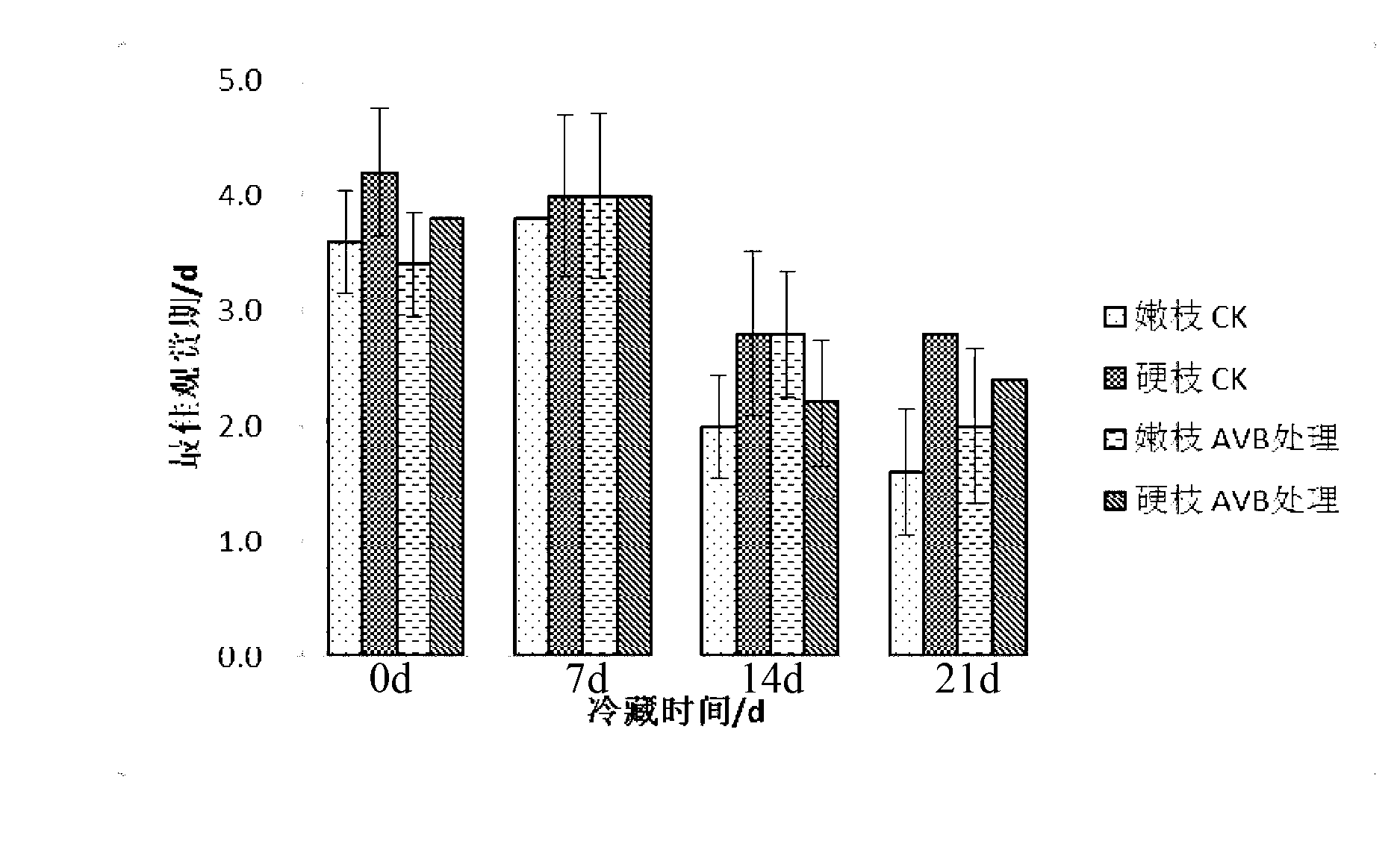

[0067] The specific method of harvesting flower branches is to select flower branches with a diameter of >30cm and consistent growth during the flower bud dew stage (the sepals are split, the outer petals are exposed, the sepals move to the middle and lower parts of the flower buds, and the top of the flower buds become loose and soft). receive. The hard branch cut flowers of the present invention (including the annual branch part and the biennial branch part) are harvested as shown in the cutting position figure 1 As shown in ③, the standard is the length > 45cm; the cutting position of traditional twig cut flowers refers to figure 1 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com