Knitting machine

A knitting machine and frame technology, applied in knitting, warp knitting, flat warp knitting machines, etc., can solve the problems of single fabric patterns, reduce factory or enterprise benefits, and reduce consumers, so as to meet different needs, The effect of improving the overall quality and reducing looseness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

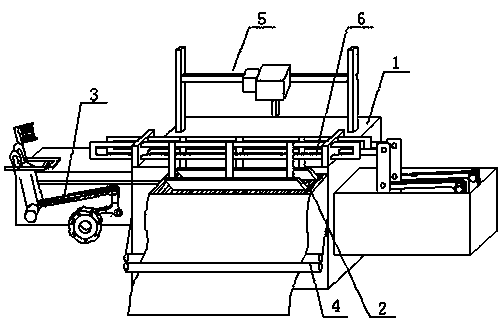

[0042] refer to figure 1 , as shown in the legend, a knitting machine for knitting various styles of fabrics, including a frame 1, a needle bed 2, a warp thread feeding device (not shown in the figure), a bar traverse mechanism 3, a pulling roll The take-up mechanism 4 and the transmission mechanism (not shown in the figure), the knitting machine also includes: the weft yarn feeding device 5, which is arranged on the frame 1, and provides weft yarn during the weaving process of the knitting machine; the pattern knitting device 6, which is arranged on the frame 1 above, a pattern for weaving fabrics.

[0043] The working principle of the present invention is introduced below: during the weaving process of the knitting machine, the weft yarn feeding device 5 provides the weft yarn for weaving, and when the warp yarn is looped, it is woven into the body together with the warp yarn; During the process, it interacts with the transmission mechanism to weave different patterns on th...

Embodiment 2

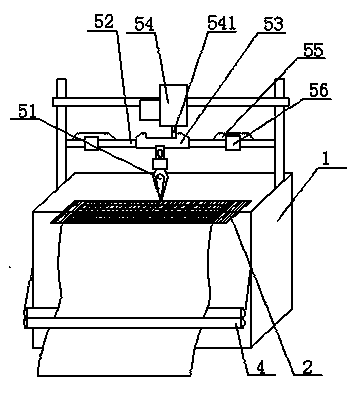

[0045] refer to figure 1 , figure 2 , as shown in the legend, the rest are the same as in Embodiment 2, the difference is that the weft yarn feeding device 5 includes: a yarn feeder 51, which is used to provide the weft yarn required in the weaving process; guide rail 52, which is arranged on the frame 1; The croissant device 53 is movably connected to the guide rail 52 and connected to the yarn feeder 51 ; the driving device 54 is arranged on the frame 1 for driving the croissant device 53 to move back and forth along the guide rail 52 . Start the knitting machine, the knitting machine runs, the computer controls the driving device 54, and the driving device 54 begins to move. When moving to a certain position, it drives the claw device 53 to move synchronously. Move with the claw device 53 . While the warp yarn is being looped, the yarn feeder 51 (into the thread through the side spring device) will move back and forth along with the weft yarn, and at the same time be wov...

Embodiment 3

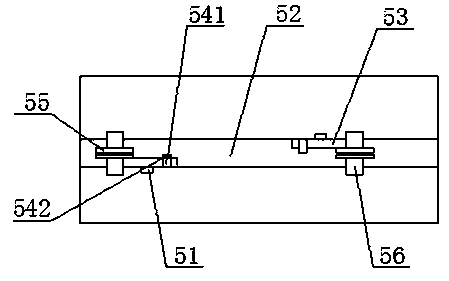

[0047] refer to figure 2 , as shown in the legend, the rest are the same as in Embodiment 2, the difference is that the guide rail 52 is provided with a release 55, and the driving device 54 is provided with a telescopic driving rod 541 (the driving rod 541 is provided with a return spring device, The elongation and reset are realized by the electromagnet), the driving rod 541 pushes the horn device 53 to move back and forth along the guide rail 52, the tripper 55 is used to separate the driving rod 541 from the horn device 53, the driving rod 541 is provided with a tripping part 542, When the tripping part 542 is in contact with the tripper 55, due to the setting of the spring return device, the driving rod 541 resets and disengages from the tripper 55; a limit block 56 is also arranged on the guide rail 52 to limit the working stroke of the horn device 53 . The trippers 55 are arranged in pairs on the guide rails 52 and are respectively located on both sides of the claw de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com