Flame-retardant environment-protection artificial leather and making method thereof

A technology of artificial leather and manufacturing method, applied in textiles and papermaking, etc., can solve the problems of chlorine compound toxicity, large environmental protection cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

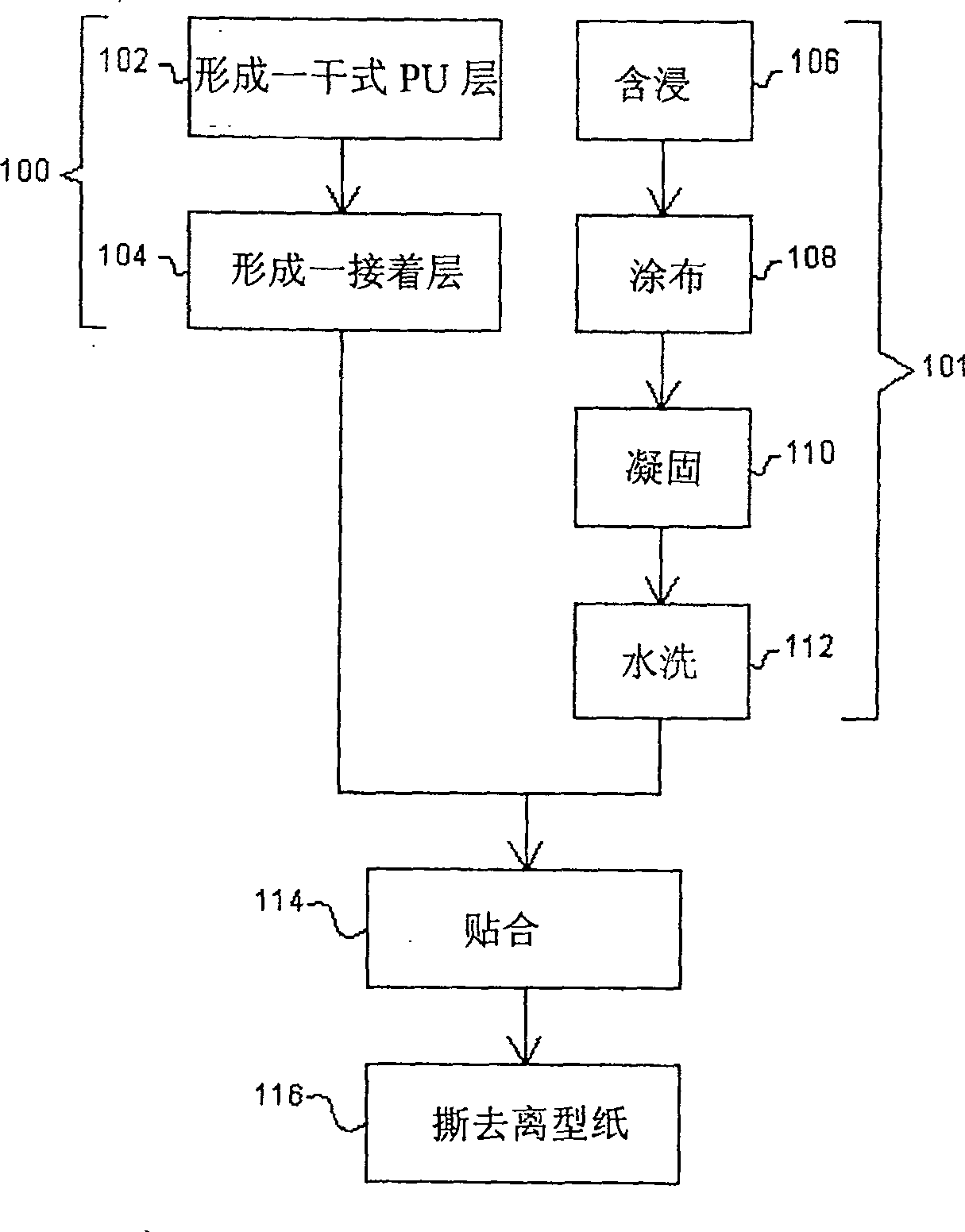

Method used

Image

Examples

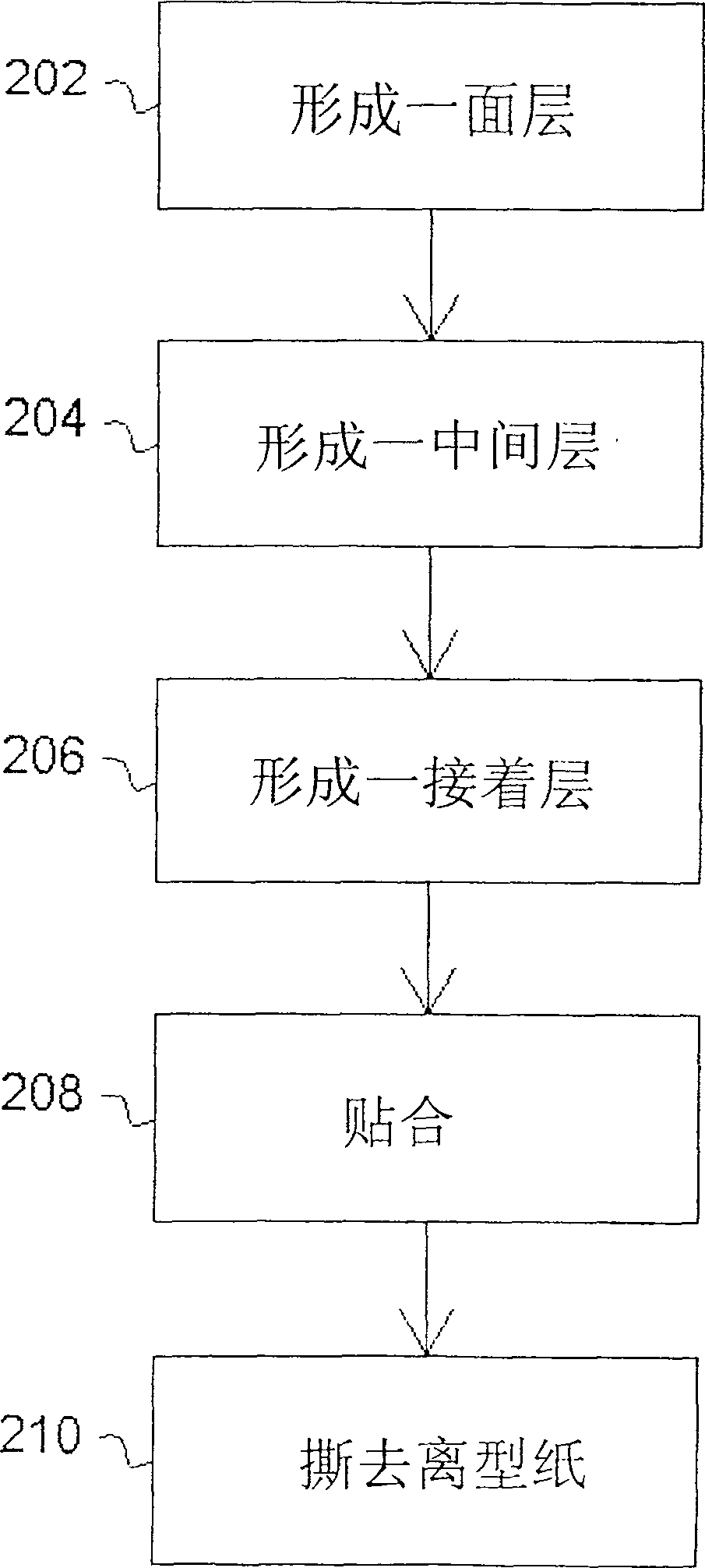

Embodiment 1

[0043] A layer of polyurethane resin coating with 12.5% solid content (containing 87.5% solvent) is coated on a release paper, wherein the viscosity of the resin coating is controlled at 1300cps / 30°C. The polyurethane resin coating was dried in an oven at 110° C. to form a one-sided layer.

[0044] A polyurethane resin coating with a high solid content is coated on the dry surface layer, wherein the coating is made of 67% by weight polyurethane resin (solid content 93%), 20% phosphorus flame retardant and antimony oxide (Sb 2 o 3 ) (the weight ratio of phosphorus flame retardant and antimony oxide is 2:1), 1% interface agent, 4% hardener, 6% filler and 2% colorant, and its viscosity is controlled at 25000cps / 30℃. The polyurethane resin coating with high solid content was baked and hardened by an oven at 160° C. to form an intermediate layer.

[0045] On the hardened intermediate layer, coat a polyurethane resin coating with a solid content of 35% to form an adhesive layer...

Embodiment 2

[0050] A layer of foamable polyurethane resin coating with a solid content of 12.5% is coated on the release paper, wherein the viscosity of the resin coating is controlled at 1300cps / 30°C. The polyurethane resin coating was dried in an oven at 110° C. to form a one-sided layer.

[0051] A polyurethane resin coating with a high solid content is coated on the dry surface layer, wherein the coating is made of 40% by weight polyurethane resin (solid content 93%), 12% phosphorus flame retardant and antimony oxide (Sb 2 o 3 ) (the weight ratio of phosphorus flame retardant and antimony oxide is 2:1), 0.5% interface agent, 7% hardener, 38.5% filler and 2% colorant, and its viscosity is controlled at 25000cps / 30℃ . The polyurethane resin coating with high solid content was baked and hardened by an oven at 130° C. to form an intermediate layer.

[0052]On the hardened intermediate layer, coat a polyurethane resin coating with a solid content of 35% to form an adhesive layer. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com