Polyurethane pu synthetic leather semi-finished product line

A synthetic leather and polyurethane technology, applied in textiles and papermaking, etc., can solve the problems of troublesome waste water treatment, a large amount of acid waste water, and high treatment costs, and achieve the effect of reducing treatment costs, avoiding acid waste water, and reducing process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

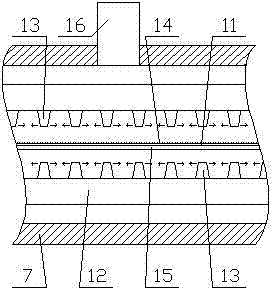

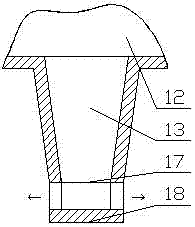

[0042] combine figure 2 and image 3 As shown, the top and the bottom in the oven 7 are respectively fixed with a hot air pipe 12, and the side of the hot air pipe 12 facing the cloth 11 is respectively provided with an air outlet pipe 13, and the air outlet 17 of the air outlet pipe 13 The wind direction of the hot blast that blows out is horizontal direction; Described air outlet 17 is located at an end of air outlet pipe 13 facing cloth 11, is provided with windshield 18 between the air outlet 17 of described air outlet pipe 13 and beep 11; The two side edge portions of above-mentioned wind deflector 18 are horizontal.

Embodiment 2

[0044] combine figure 2 and Figure 4 As shown, the top and the bottom in the oven 7 are respectively fixed with a hot air pipe 12, and the side of the hot air pipe 12 facing the cloth 11 is respectively provided with an air outlet pipe 13, and the air outlet 17 of the air outlet pipe 13 The hot air that blows out is blown to the side away from cloth 11; Described air outlet 17 is arranged on the end of air outlet pipe 13 facing cloth 11, is provided with windshield 18 between the air outlet 17 of described air outlet pipe 13 and cloth 11 ; The two sides of the windshield 18 are inclined to the side away from the cloth 11 .

Embodiment 3

[0046] combine figure 2 and Figure 5 As shown, the top and the bottom in the oven 7 are respectively fixed with a hot air pipe 12, and the side of the hot air pipe 12 facing the cloth 11 is respectively provided with an air outlet pipe 13, and the air outlet 17 of the air outlet pipe 13 The wind direction of the blown hot air is horizontal; the air outlet 17 is arranged on the side wall of the air outlet pipe 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com