High-frequency induction heating brazing method of molybdenum-rhenium alloy foil

A high-frequency induction heating, molybdenum-rhenium alloy technology, applied in the field of high-frequency induction heating brazing, welding of refractory metals, can solve the problems of low joint strength, low welding production efficiency, burn-through or fracture, etc., to meet the quality requirements and use strength requirements, the joint quality is stable, and the welding speed is fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

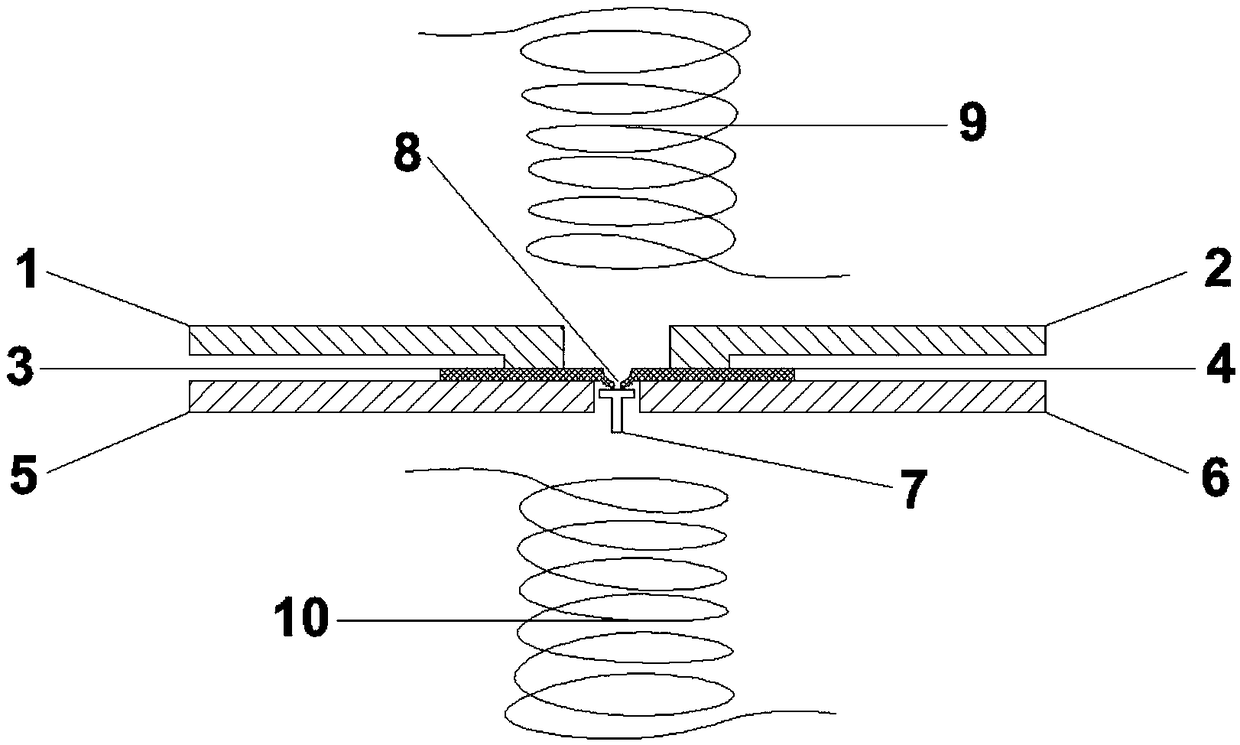

[0024] In this embodiment, the Mo50-Re50 alloy foil is used as the workpiece to be welded, and the size of the foil is 20mm×80mm, and the thickness is 0.18mm.

[0025] The specific high-frequency induction heating brazing process steps of Mo50-Re50 alloy foil are as follows:

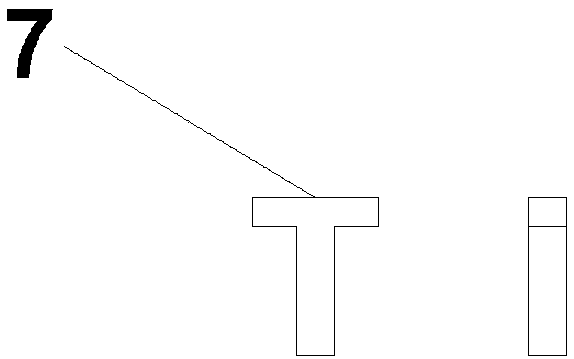

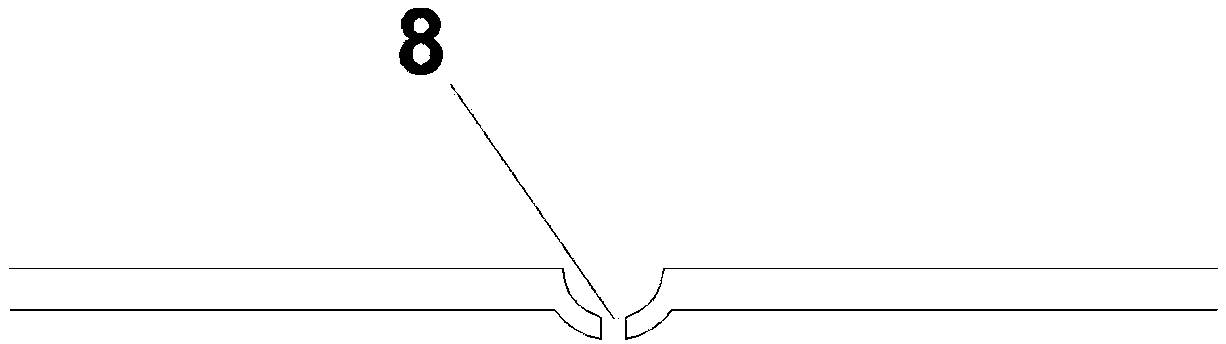

[0026] (1) Grind the downward bending direct welding area 8 of Mo50-Re50 alloy foils 3 and 4 and the surrounding upper and lower surfaces with sandpaper, and the non-welding area should also be polished to make the surface leak metallic luster, and use an ultrasonic cleaner to clean the welder parts for cleaning. The specific method is as follows: use 1200# sandpaper to polish the surface areas of both sides of the lower bending area of the molybdenum-rhenium alloy foil, and use 800# sandpaper to polish the non-welding area of 3~6mm around the edge, making it leak metallic luster; Put the sample into a glass container with acetone, perform ultrasonic cleaning at 40°C for 20 minutes, and then perform...

Embodiment 2

[0034] In this embodiment, the Mo50-Re50 alloy foil is used as the workpiece to be welded, and the size of the foil is 20mm×80mm, and the thickness is 0.18mm.

[0035] The specific high-frequency induction heating brazing process steps of Mo50-Re50 alloy foil are as follows:

[0036] (1) Grind the downward bending direct welding area 8 of Mo50-Re50 alloy foils 3 and 4 and the surrounding upper and lower surfaces with sandpaper, and the non-welding area should also be polished to make the surface leak metallic luster, and use an ultrasonic cleaner to clean the welder parts for cleaning. The specific method is as follows: use 1200# sandpaper to polish the surface areas of both sides of the lower bending area of the molybdenum-rhenium alloy foil, and use 800# sandpaper to polish the non-welding area of 3~6mm around the edge, making it leak metallic luster; Put the sample into a glass container with acetone, perform ultrasonic cleaning at 40°C for 20 minutes, and then perform...

Embodiment 3

[0044] In this embodiment, the Mo50-Re50 alloy foil is used as the workpiece to be welded, and the size of the foil is 20mm×80mm, and the thickness is 0.18mm.

[0045] The specific high-frequency induction heating brazing process steps of Mo50-Re50 alloy foil are as follows:

[0046] (1) Grind the downward bending direct welding area 8 of Mo50-Re50 alloy foils 3 and 4 and the surrounding upper and lower surfaces with sandpaper, and the non-welding area should also be polished to make the surface leak metallic luster, and use an ultrasonic cleaner to clean the welder parts for cleaning. The specific method is as follows: use 1200# sandpaper to polish the surface areas of both sides of the lower bending area of the molybdenum-rhenium alloy foil, and use 800# sandpaper to polish the non-welding area of 3~6mm around the edge, making it leak metallic luster; Put the sample into a glass container with acetone, perform ultrasonic cleaning at 40°C for 20 minutes, and then perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com