Slitting striping method of PS aluminum base belt-material

A technology of slitting strips and strips, which is applied in the field of aluminum alloy manufacturing, can solve the problems of waste of equipment capacity, low yield rate, and low production efficiency, and achieve improved production efficiency, improved yield rate and production efficiency, and significant economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

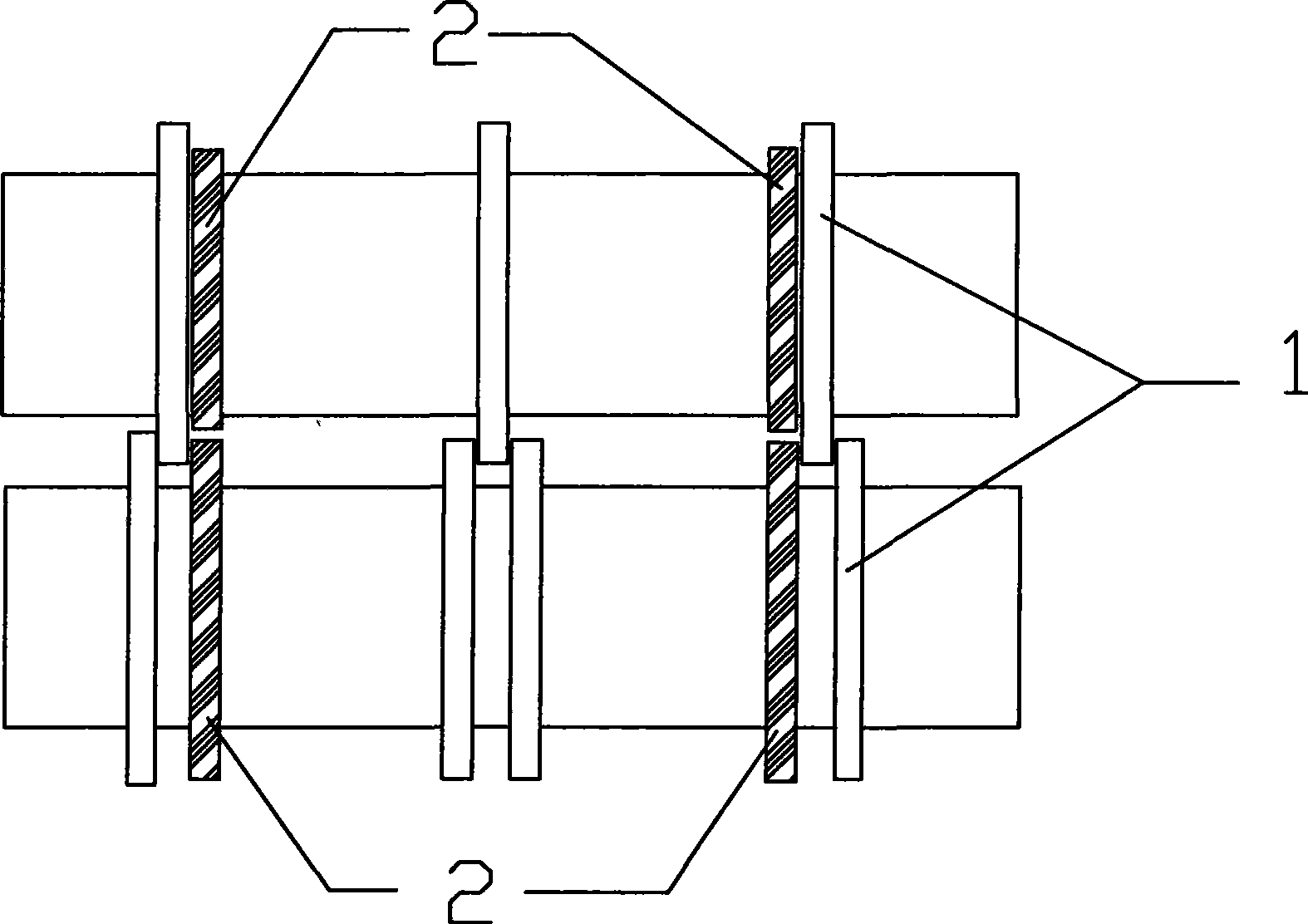

[0022] The upper part of the circular knife assembly rack of the slitting machine row is provided with three slitting circular blades, and the lower part is provided with four slitting circular knives; the two sides of the lower part are respectively provided with a slitting circular blade which is close to the slitting circular blades on both sides of the upper part. In the middle of the lower part, there are two circular blades that are arranged close to the left and right sides of the circular blade in the middle of the upper part.

[0023] The PS plate-based aluminum coil that has been rolled to the finished thickness is first straightened and cleaned by the stretch bending straightening machine. After the strip is straightened, the flatness is less than 10I and the wave height cannot exceed 3mm.

[0024] The straightened aluminum coil is slit on both sides by the slitting machine row, and the slitting circular blades on both sides of the circular knife assembly frame are p...

Embodiment 2

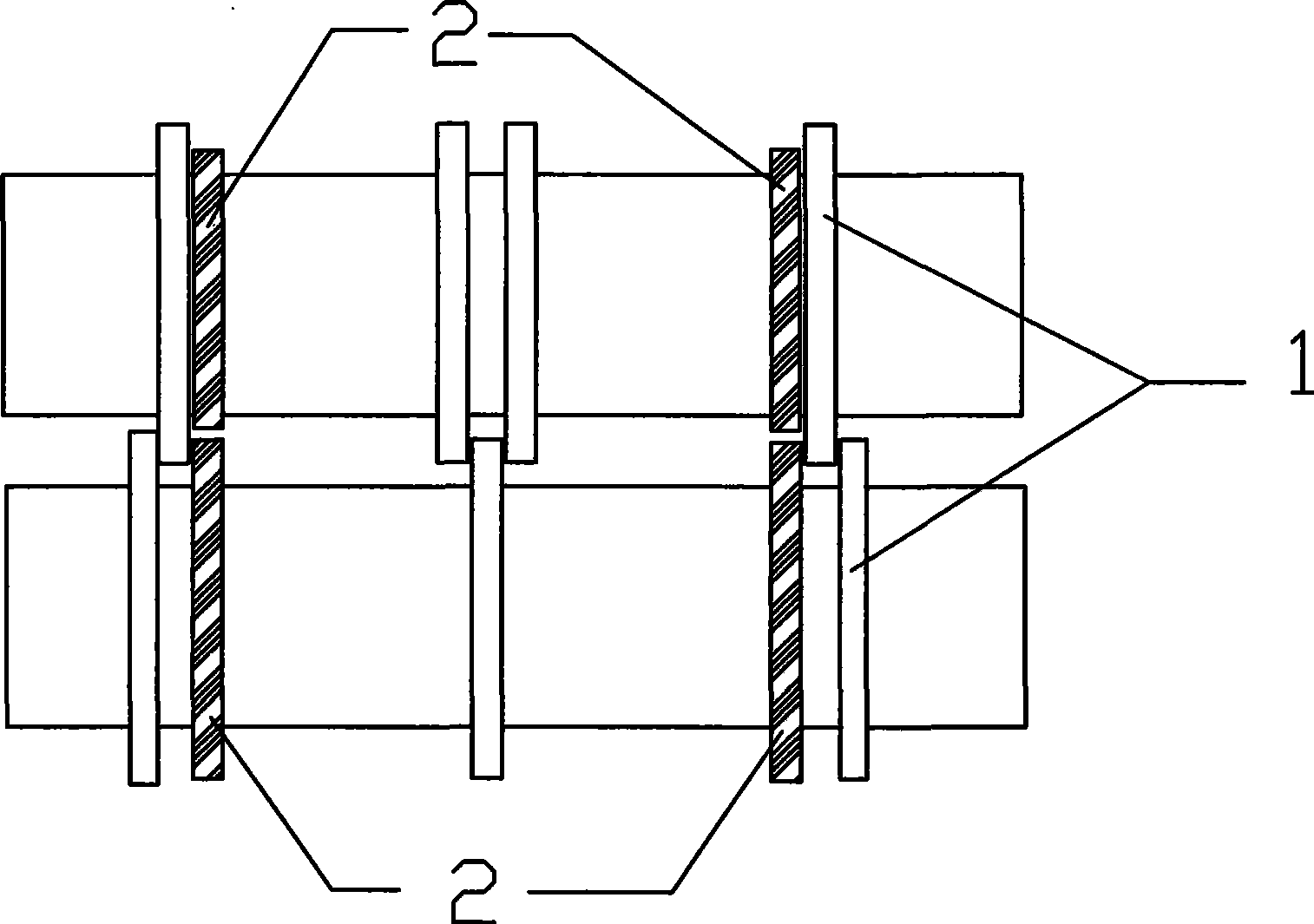

[0030] The lower part of the circular knife assembly frame of the slitting machine row is provided with three slitting circular blades, and the upper part is provided with four slitting circular knives; the two sides of the upper part are respectively provided with a corresponding slitting circular blade which is closely arranged with the slitting circular blades on both sides of the lower part, In the middle of the upper part, there are two round blades that are arranged close to the left and right sides of the round blade in the middle of the bottom.

[0031] The PS plate-based aluminum coil that has been rolled to the finished thickness is first straightened and cleaned by the stretch bending straightening machine. After the strip is straightened, the flatness is less than 10I and the wave height cannot exceed 3mm.

[0032] The straightened aluminum coil is slit on both sides by the slitting machine row, and the slitting circular blades on both sides of the circular knife as...

Embodiment 3

[0038] The upper part of the circular knife assembly rack of the slitting machine row is provided with three slitting circular blades, and the lower part is provided with four slitting circular knives; the two sides of the lower part are respectively provided with a slitting circular blade which is close to the slitting circular blades on both sides of the upper part. In the middle of the lower part, there are two circular blades that are arranged close to the left and right sides of the circular blade in the middle of the upper part.

[0039] The PS plate-based aluminum coil that has been rolled to the finished thickness is first straightened and cleaned by the stretch bending straightening machine. After the strip is straightened, the flatness is less than 10I and the wave height cannot exceed 3mm.

[0040] The straightened aluminum coil is slit on both sides by the slitting machine row, and the slitting circular blades on both sides of the circular knife assembly frame are p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com