Tunnel boring dust prevention system

A technology of dust removal system and roadway, applied in the directions of dust prevention, fire prevention, safety device, etc., can solve the problems affecting the promotion and application of mechanization of comprehensive excavation in rock roadway, the threat to the health of employees, and the inability to engage in other work, so as to ensure physical health, The effect of improving visibility and controlling dust explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

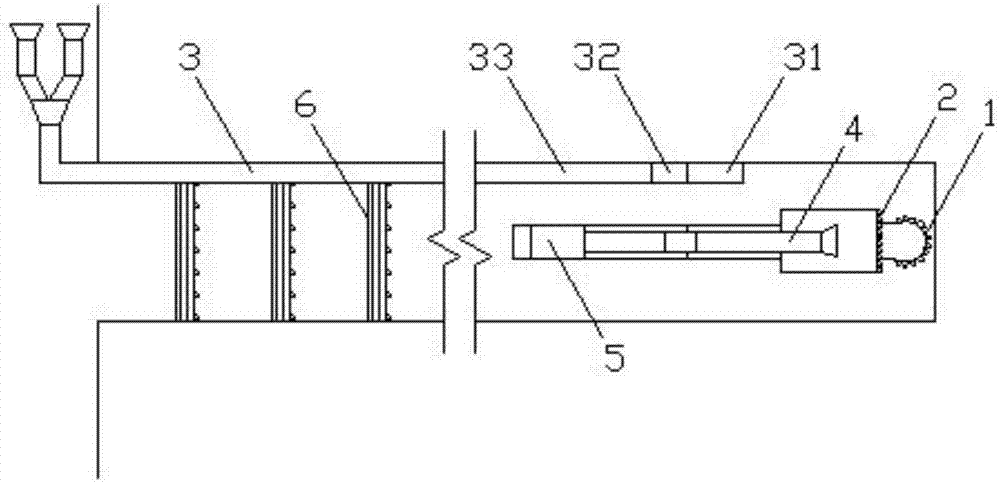

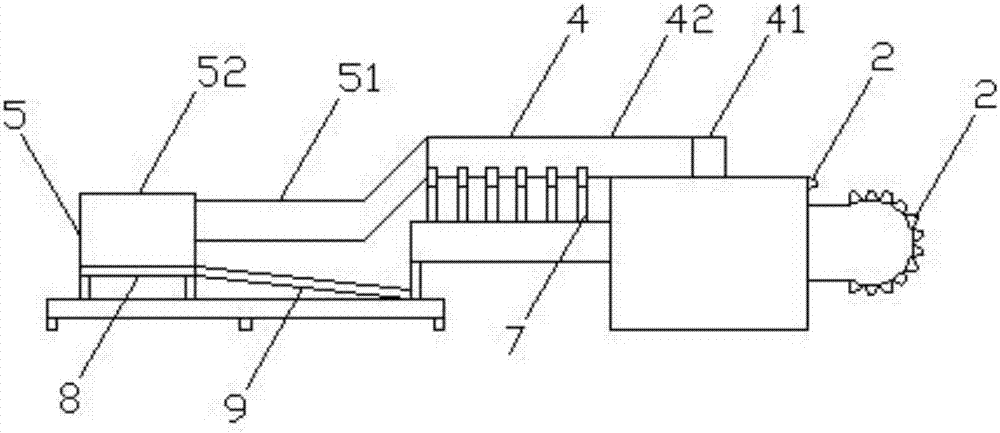

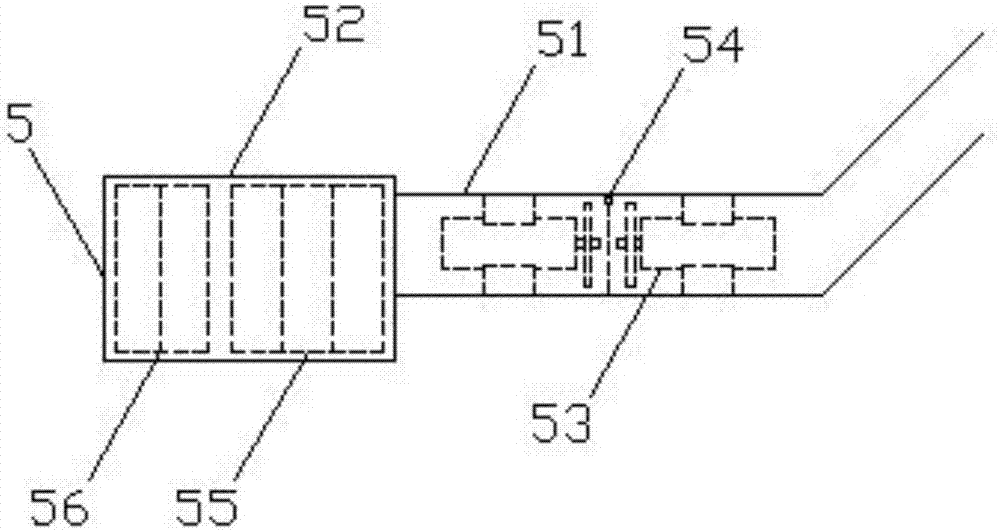

[0026] Such as Figure 1-5 As shown, the roadway excavation dust prevention system includes the comprehensive excavator spray system, dust removal system and roadway spray system, and the driver of the fully mechanized excavator adopts a positive pressure breathing device.

[0027] The spray system of fully mechanized excavator includes inner spray 1 and outer spray 2. The water outlet of inner spray 1 is arranged in a dot-shaped spherical shape on the cutting head of the fully mechanized excavator, and the water outlet of outer spray 2 is in a linear shape behind the cutting head. Arranged horizontally.

[0028] The spray system of the fully mechanized excavator is connected to the water supply pipeline. The main pipe of the water supply pipeline is provided with a water quality filter greater than or equal to 400 mesh. The water supply pipeline is divided into three branches at the fully mechanized excavator. The first branch is directly connected to the external spray 2, T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com