Fire extinguishing and explosion proofing equipment employing liquid nitrogen as fire extinguishing agent

A technology of explosion-proof equipment and fire extinguishing agent, which is applied in mining equipment, dust prevention, fire rescue, etc. It can solve the problems of storage tank performance not meeting the specified requirements, frequent explosion accidents, and poor thermal insulation performance, so as to avoid personal and property losses , Ensure fire extinguishing efficiency, control the effect of gas explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation of the liquid nitrogen storage tank provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

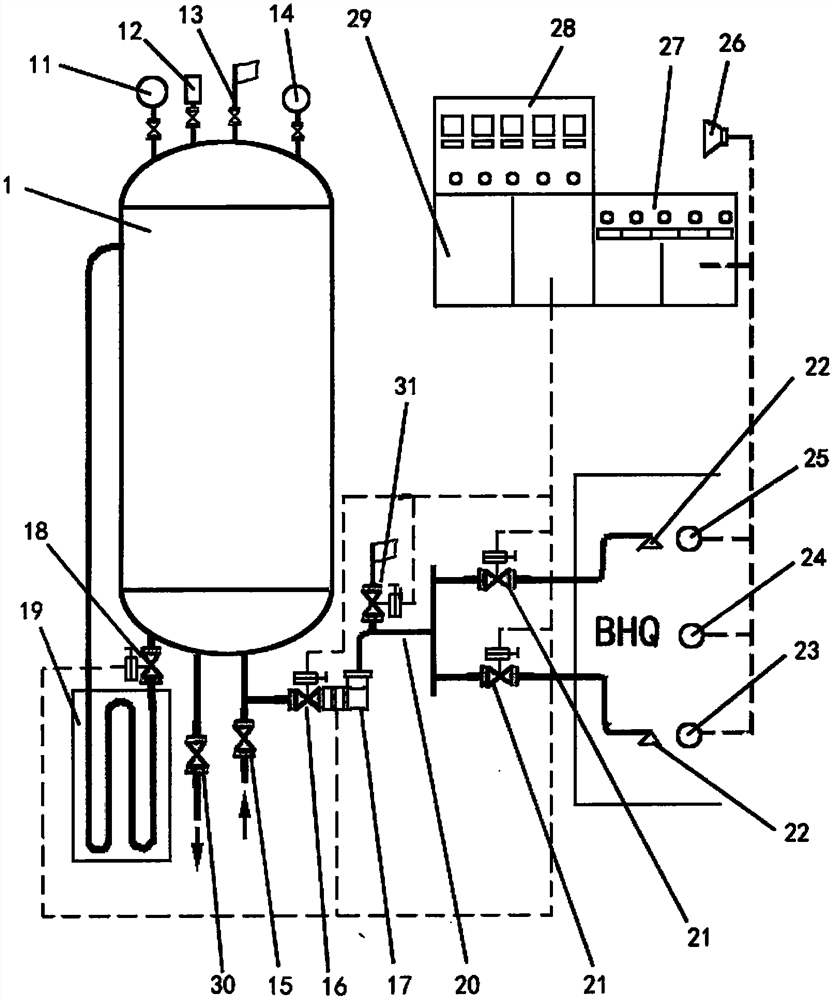

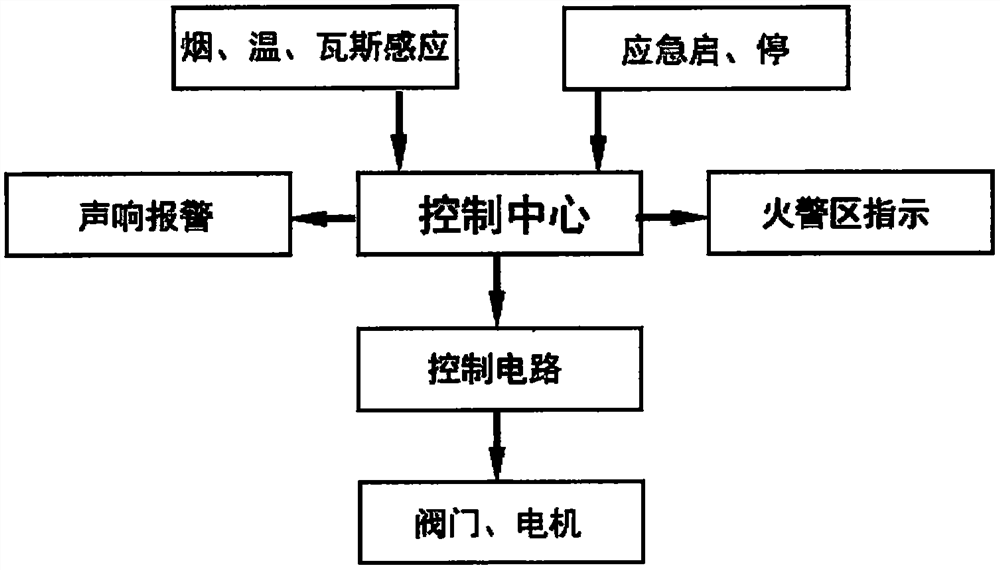

[0025] as attached figure 1 , figure 2 As shown, a fire extinguishing and explosion-proof equipment using liquid nitrogen as a fire extinguishing agent is composed of a storage tank 1, an evaporator 19, an ultra-low temperature liquid pump 17, an electric automatic control valve group, an insulating pipe 20, a nozzle 22, and a control system.

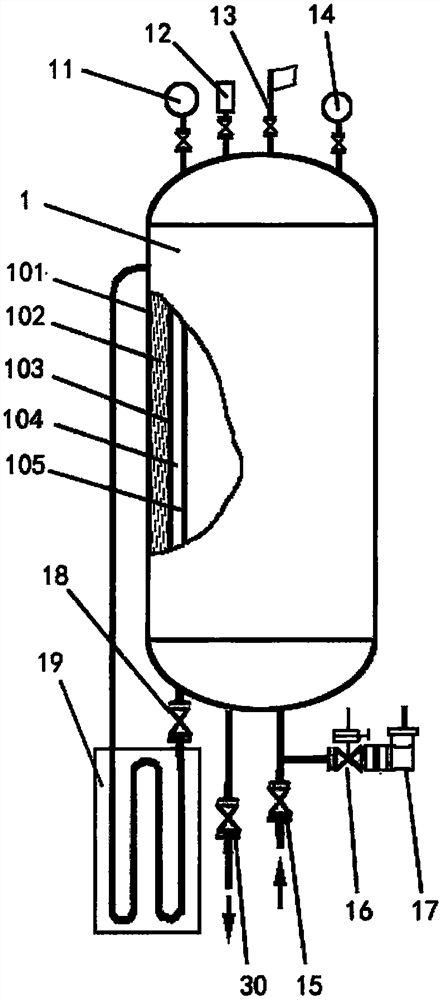

[0026] The storage tank 1 is a cylindrical tank body with an arched head. The tank body wall is divided into three layers, which are made of stainless steel welding machine. The heat insulating layer 102 is made of foamed polyurethane or perlite, and the space between the middle liner 103 and the inner liner 105 is filled with a liquid argon layer 104 after vacuuming. The three-layer tank wall and double-layer heat insulation can keep the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com