High efficient dedusting system with air channel arranged in central part of heading machine

A technology of dust removal system and roadheader, which is applied to slitting machinery, earth-moving drilling and mining, etc., can solve the problems of poor integration, inflexible operation, and large space occupation, so as to reduce the incidence of disease, improve the working environment, and control coal dust. explosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described in conjunction with the accompanying drawings, and the embodiments are used to illustrate the present invention, but not to limit it in any way.

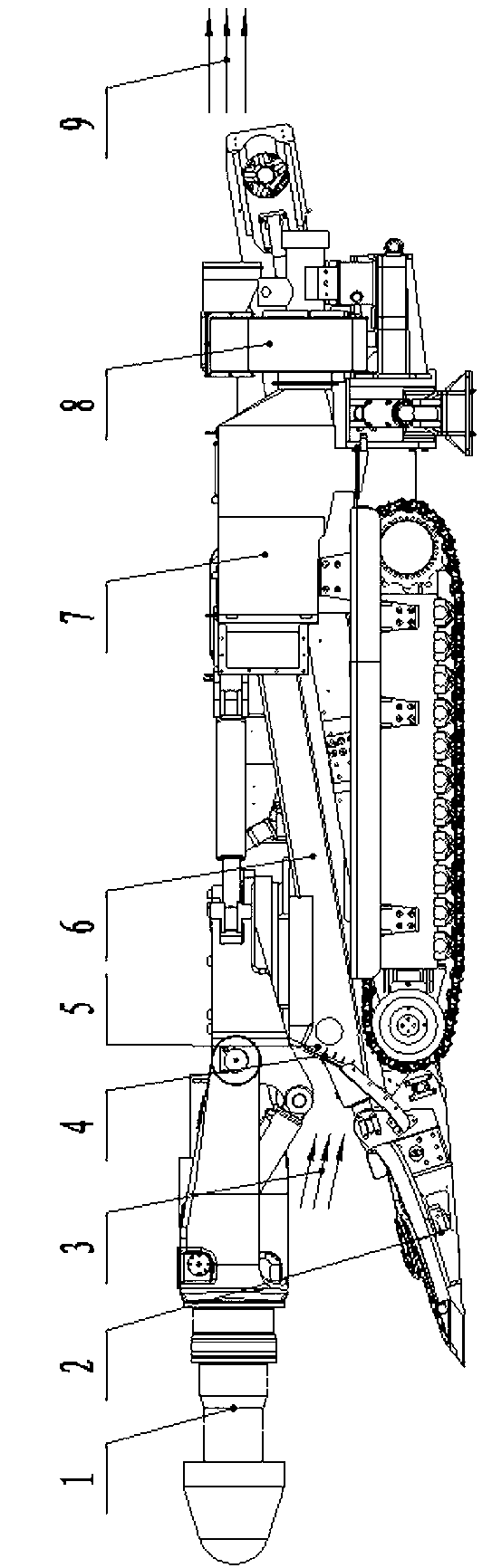

[0020] The high-efficiency dust removal system with the air duct arranged in the middle of the roadheader includes an air inlet 4, an air duct 6, a dust collector 7 and a fan 8, and the two ends of the air duct 6 are respectively connected to the air inlet 4 and the dust collector 7.

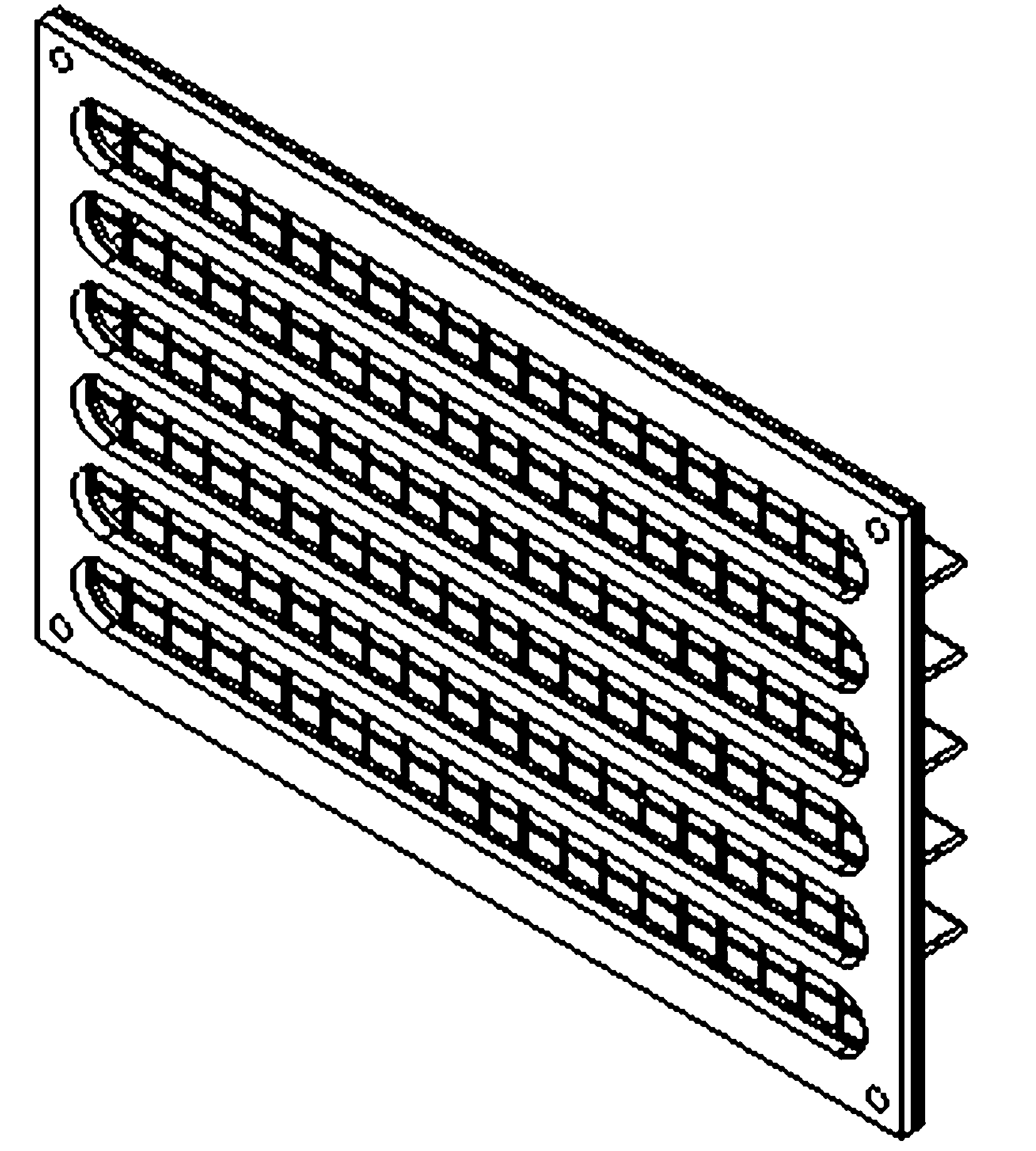

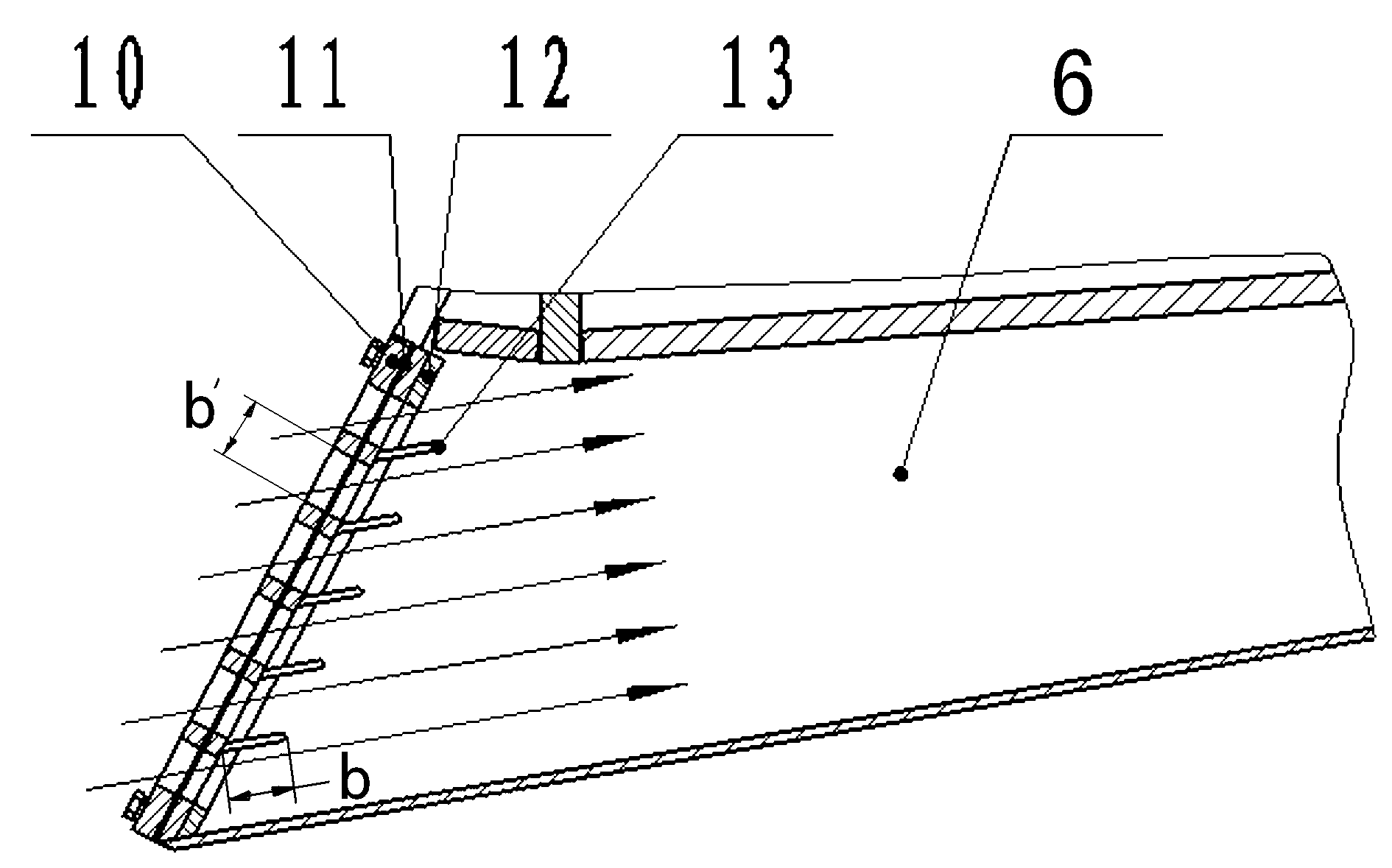

[0021] The air inlet 4 is arranged at the front end of the machine frame between the cutting part 1 and the loading part 2 of the roadheader. A deflector is installed at the air inlet, and the deflector includes an upper panel 10 of the air inlet, an air inlet mesh 11 and a lower panel 12 of the air inlet connected in sequence, the upper panel 10 of the air inlet and the lower panel 12 of the air inlet are a grid structure, A deflector 13 is arranged on the lower edge o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com