Anti-static base cloth for filter material and production method for anti-static base cloth

A filter material and antistatic technology, applied in the direction of filtration separation, separation method, chemical instrument and method, etc., can solve the problems of poor spinning performance, low metal fiber cohesion, inability to use medium and high temperature filtration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

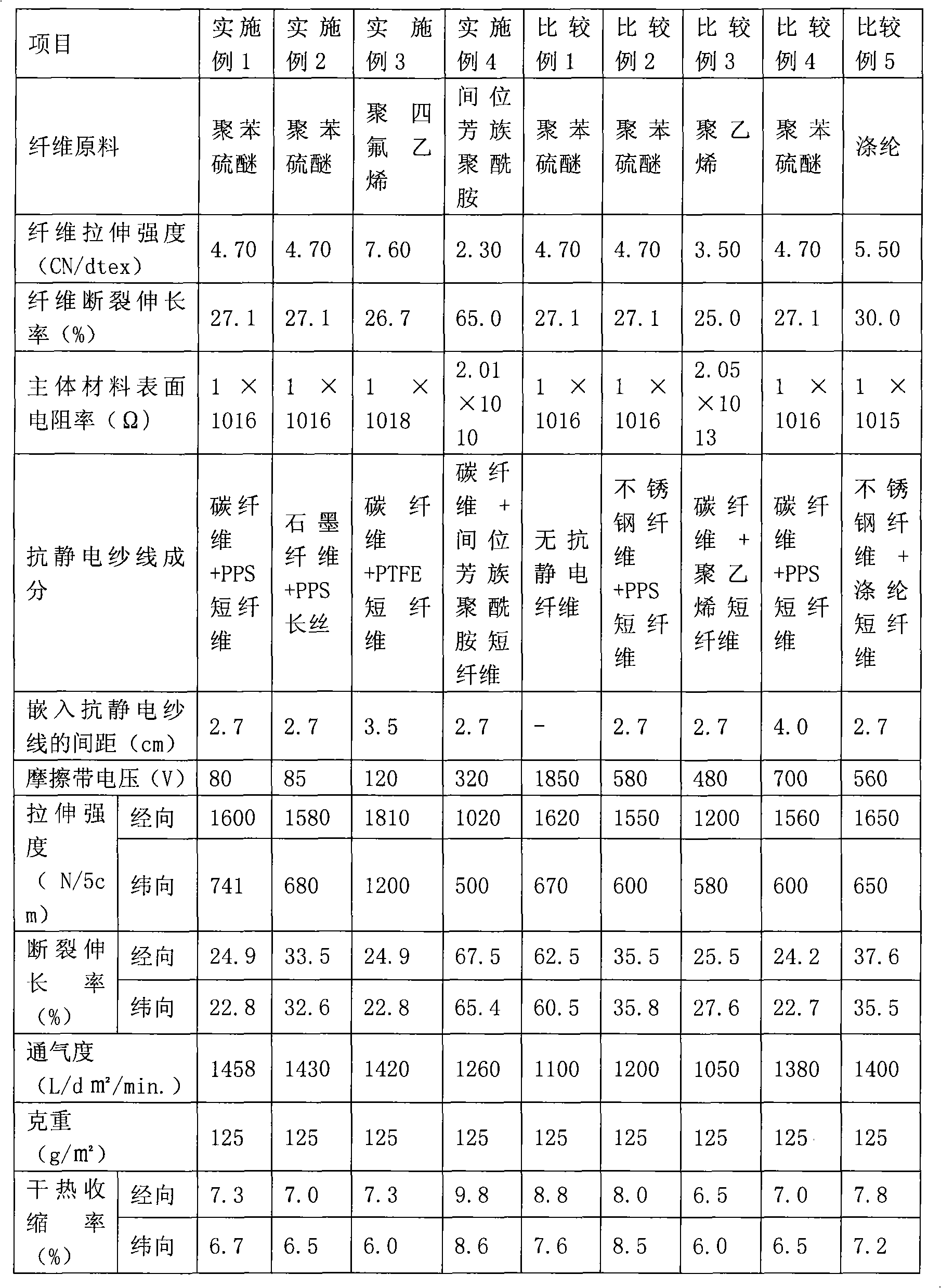

Examples

Embodiment 1

[0036] An antistatic base cloth for filter materials, which is woven with PPS yarns with a warp fineness of 240D and a weft fineness of 700D, and an antistatic yarn made by mixing a carbon fiber and PPS staple fiber every 2.7cm in the warp direction Interweave to obtain a plain weave fabric. When weaving, the warp density is set to be 125 threads / 10cm, and the weft density is 65 threads / 10cm. During the weaving process, the yarn before weaving or the base fabric after weaving is heat-set , the technological conditions of the heat setting process are: the heat setting temperature is 85°C, the heat setting humidity is 80%, the number of heat setting times: 1 time, the base fabric is obtained, and its physical properties are shown in Table 1.

Embodiment 2

[0038] An antistatic base cloth for filter materials, which is woven with PPS yarns with a warp fineness of 240D and a weft fineness of 700D, and an antistatic yarn made by compounding a graphite fiber and a PPS filament every 2.7cm in the warp direction Threads were interwoven to obtain a plain weave fabric. The weaving process was the same as in Example 1 to obtain a base cloth. The results of its physical properties were shown in Table 1.

Embodiment 3

[0040] An antistatic base cloth for filter materials, which is woven with PTFE yarns with a warp fineness of 240D and a weft fineness of 700D, and an antistatic yarn made by blending with a carbon fiber and PTFE short fiber every 3.5cm in the warp direction Carry out interweaving, make plain weave fabric, its weaving process is the same as embodiment 1, makes base cloth, and its physical property result is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Warp tensile strength | aaaaa | aaaaa |

| Weft tensile strength | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com