Antistatic preprocessing solution for polyester digital inkjet printing and application

A digital inkjet and antistatic technology, applied in the field of textile printing and dyeing, can solve the problems of poor binding fastness, large energy consumption, lack of binding fastness, etc., achieve good durable antistatic performance, reduce energy consumption, and excellent color fastness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

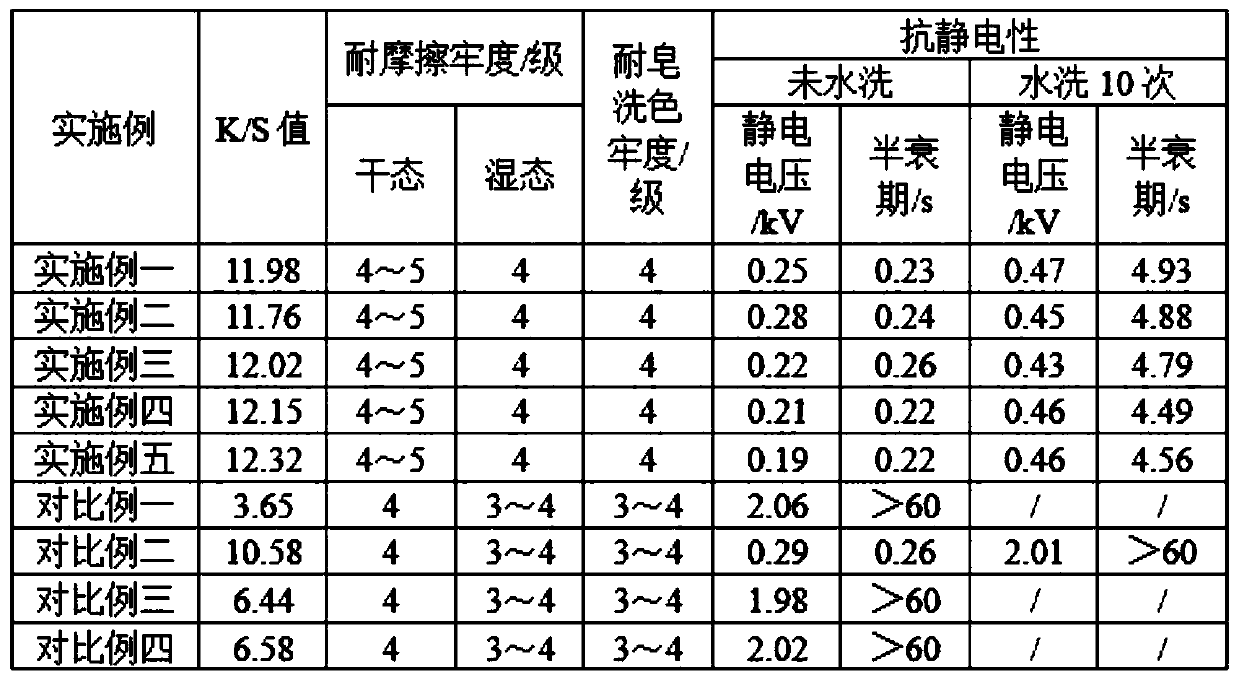

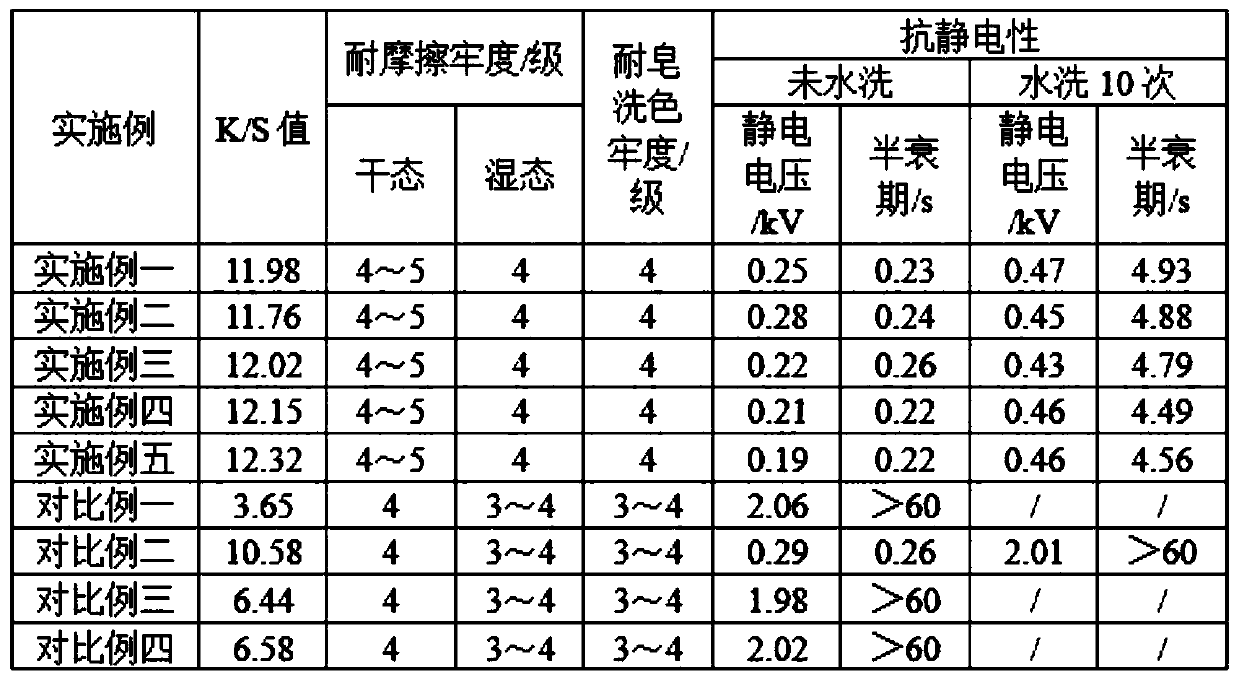

Examples

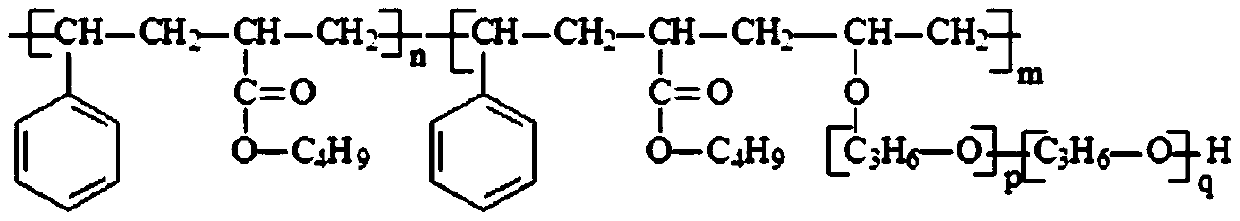

Synthetic example 1

[0038] Mix 8.0kg butyl acrylate, 2.0kg styrene, 1.0kg ammonium persulfate, 4.0kg emulsifier AES and 39.0kg water, and fully stir to form an emulsion to obtain emulsion A1;

[0039] Take 36.0kg of emulsion A, 23.0kg of allyl alcohol polyoxyethyl polyoxypropyl ether (p=3, q=3) and 15.0kg of water and mix them, and fully stir them into an emulsion to prepare emulsion B1;

[0040] In the reaction device, add 18.0kg of emulsion A1, 1.0kg of ammonium persulfate, and 7.0kg of water to mix, and heat up to 80°C while stirring, and continue to react at this reaction temperature for 30 minutes; then slowly add 74.0kg of Emulsion B1: After the addition is complete, continue to react at 80-85°C for 100 minutes, and cool to obtain the pre-condensation body A.

Synthetic example 2

[0042] 12.0kg butyl acrylate, 4.0kg styrene, 1.0kg ammonium persulfate, 3.2kg emulsifier AES and 33.8kg water were mixed, and fully stirred into an emulsion to obtain emulsion A2;

[0043] Take 36.0kg of emulsion B1, 19.0kg of allyl alcohol polyoxyethyl polyoxypropyl ether (p=2, q=4) and 15.0kg of water and mix them, and fully stir them into an emulsion to prepare emulsion B2;

[0044] In the reaction device, add 18.0kg of emulsion A2, 0.5kg of ammonium persulfate, and 11.5kg of water to mix, and heat up to 80°C while stirring, and continue to react at this reaction temperature for 30 minutes; then slowly add 70.0kg of Emulsion B2: After the addition is complete, continue to react at 80-85°C for 120 minutes, and cool to obtain the pre-condensation body B.

Embodiment 1

[0047] 2.5kg of precondensate A, 1.0kg of pentaerythritol tetraacrylate, 0.4kg of carboxymethylcellulose, 0.2kg of potassium persulfate and 95.9kg of water were mixed to prepare pretreatment solution C1. Then the polyester fabric is padded with the pretreatment solution C1 and dried; then the required printing pattern is printed with an inkjet printer, and the inkjet ink is the D2551-R disperse red ink of DuPont Company of the United States. After the printing is completed, it is dried and baked on a heat-setting machine. The baking temperature is 170°C and the baking time is 60S. Finally, the above-mentioned polyester fabric was washed on a washing machine at a washing temperature of 80° C. and a washing time of 10 minutes; after washing, it was dried on a drying device to obtain an antistatic inkjet printed fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| half-life | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com