Method for preparing rubber packing containing white carbon black by gas-phase method

A fumed silica and rubber filler technology, applied in the field of rubber filler preparation, can solve the problems of difficulty in eating powder, low bulk density, and wide application of dust flying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

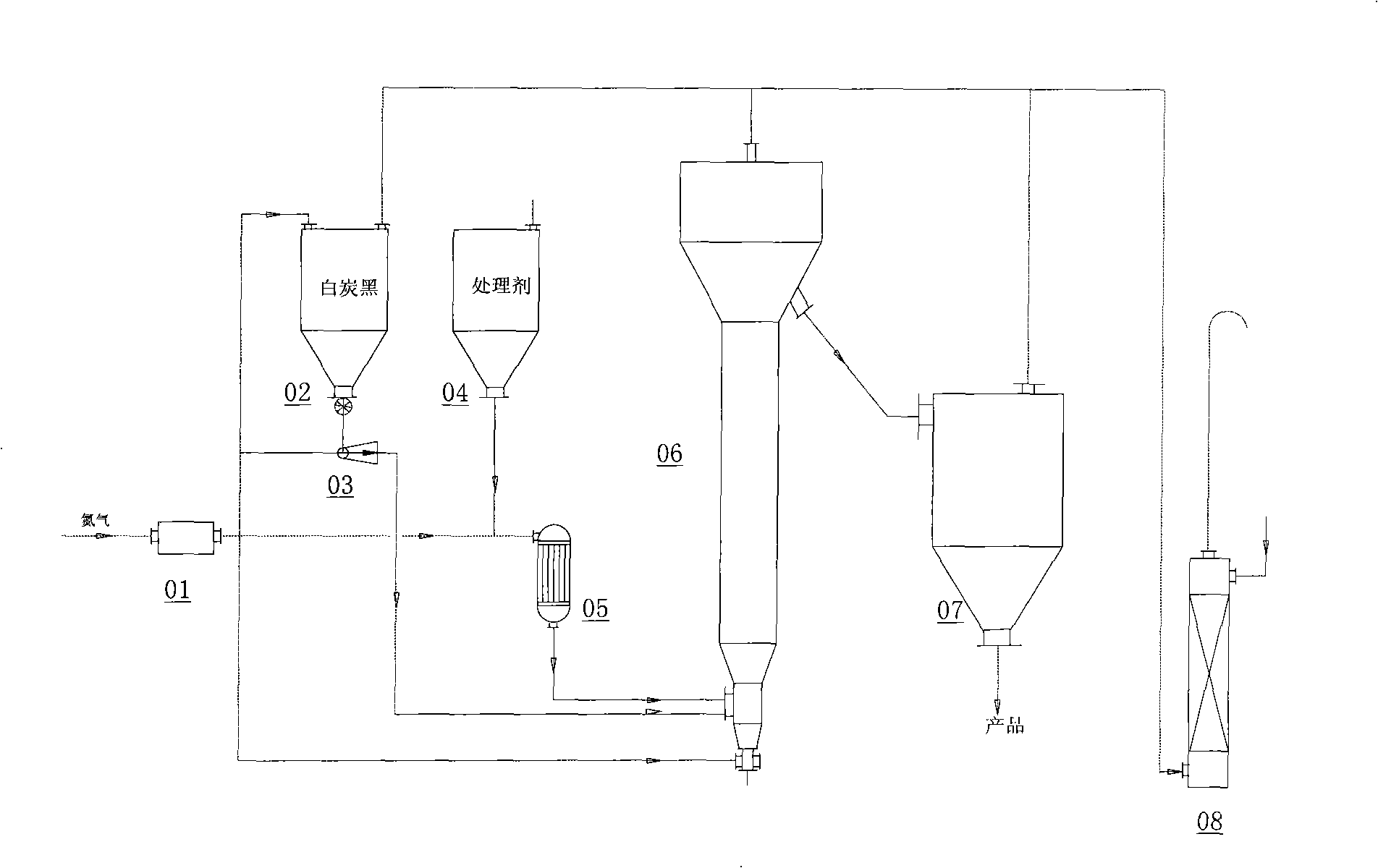

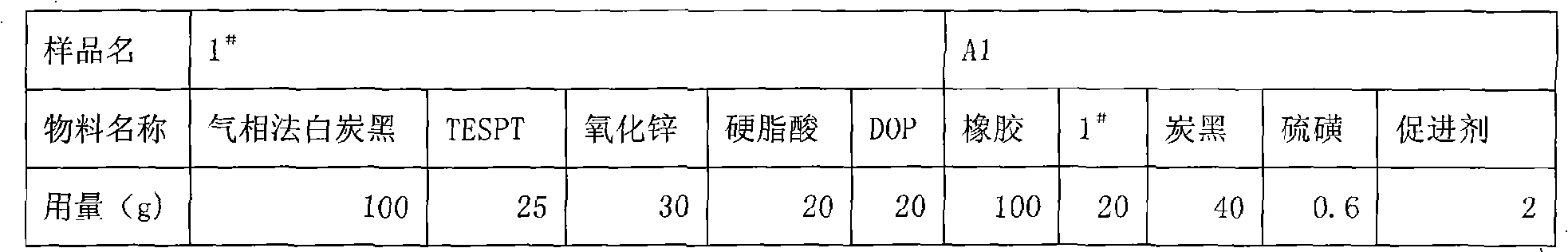

[0026] The formula is according to Table 1, and the schematic diagram of the technological process is as figure 1 , after the fumed silica is activated in the silo 02, it is accurately metered and fed through the rotary feeding valve of the feeder 03 at 50 g / min, and is continuously transported to the treatment furnace 06 with nitrogen as the carrier, while the silane coupling agent bis-(triethyl Oxysilylpropyl) tetrasulfide TESPT is vaporized in the treatment agent tank 04 by the flowmeter at 12.5g / min, and the evaporator 05 is vaporized with nitrogen as the carrier. It is sprayed into the reaction furnace 06 from the bottom of the reaction furnace 06, and fully contacts and reacts with the fumed silica. The silicon hydroxyl groups on the surface of the silica react, so that the silane coupling agent is chemically bonded to the surface of the silica. The reacted white carbon black enters the finished product tank 07 from the top of the reaction furnace 06 for collection, and...

Embodiment 2

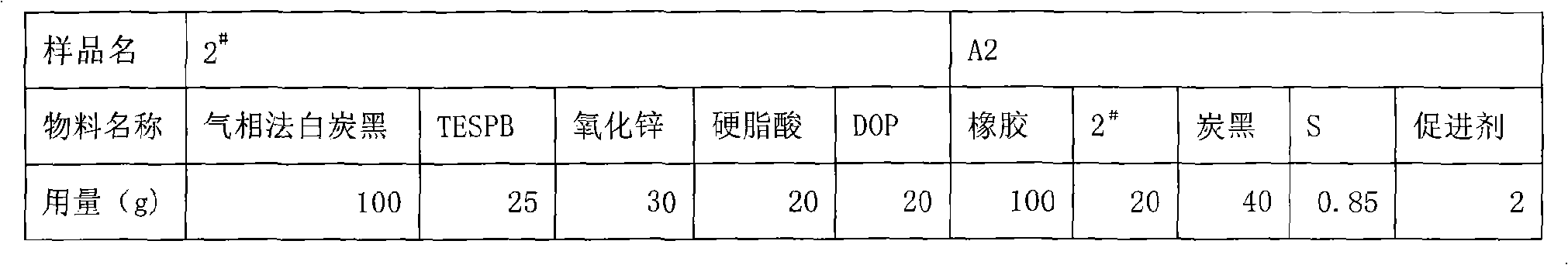

[0031] Formula is according to Table 2, and by the same method as Example 1, the silane coupling agent TESPT is changed to TESPB to obtain sample 2 # and A2.

[0032] Table 2

[0033]

Embodiment 3

[0035] According to Table 3, the fumed silica is fed through the rotary feeding valve at 50 g / min, and the silane coupling agent hexamethyldisilazane (HDMS) is fed at 7.5 g / min through the flow meter, at 180 ° C After vaporization, nitrogen is used as the carrier to enter the reactor from the bottom of the fluidized bed reactor. Control the temperature of the reactor at 180-240°C, mix the treated silica with dimethyl silicone oil, DOP, stearic acid, and zinc oxide to obtain sample 3 # , then put 3 # The sample and other additives were mixed into the rubber, and sample A3 was obtained after vulcanization, and various properties were tested according to Example 1.

[0036] table 3

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com