Gas, dust explosion and explosion suppression experiment system applicable to various optical diagnosis methods

An optical diagnosis and dust explosion technology, which is applied in the field of explosion suppression experiment system, can solve the problems that the detection window or window is too small, cannot meet the application of laser-induced optical testing technology, and cannot be fully enclosed, and achieve high-precision timing control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

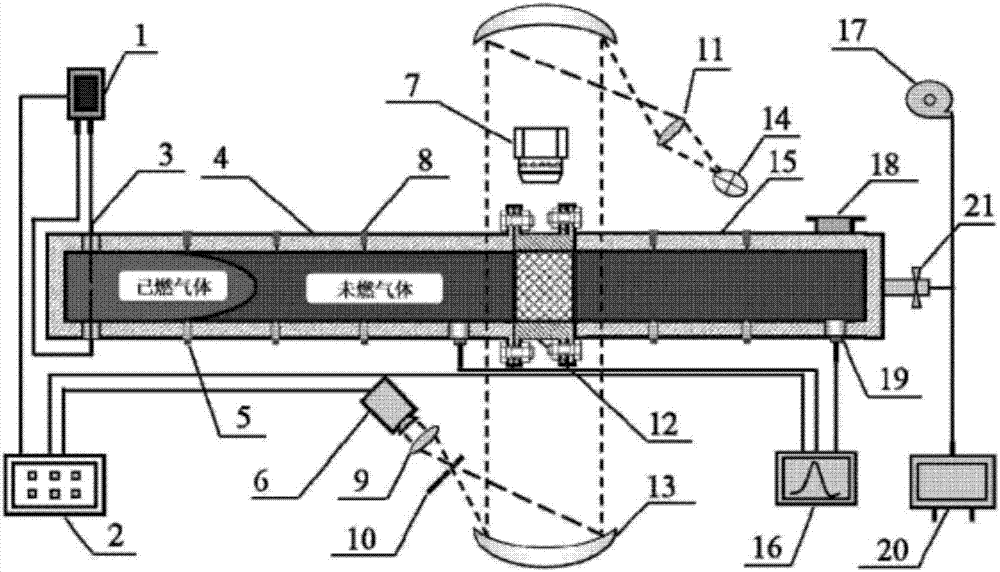

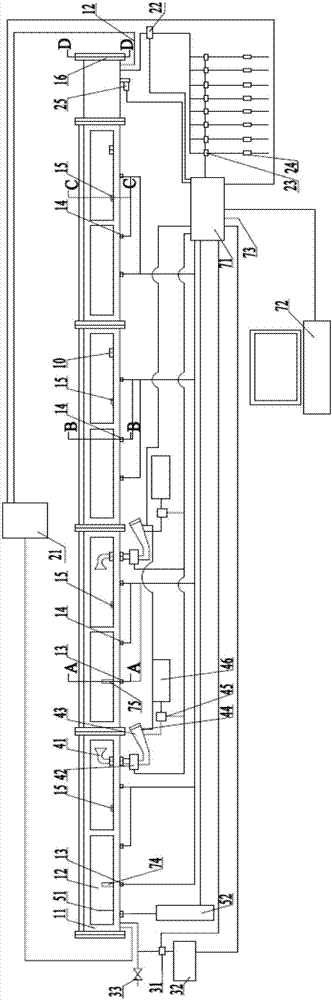

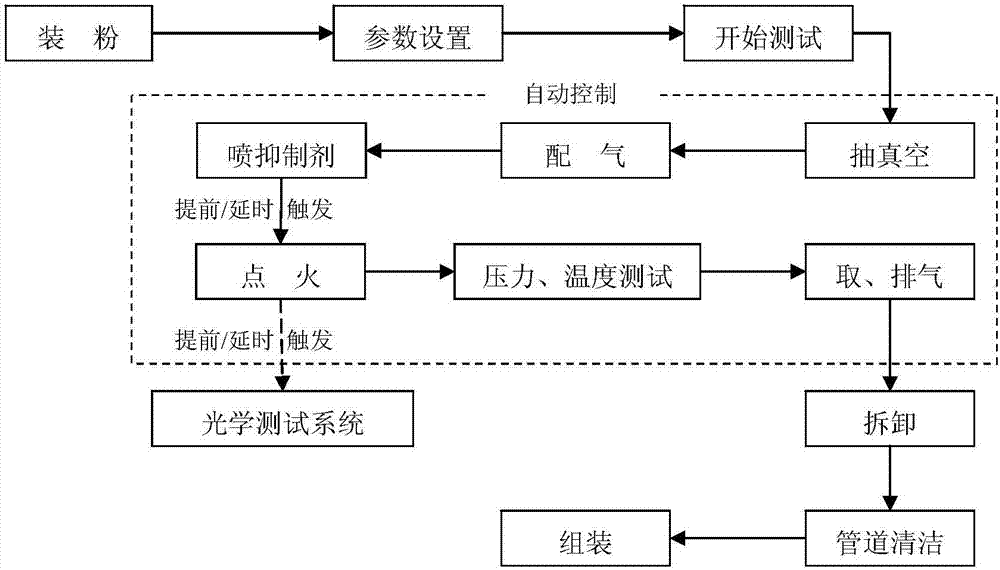

[0049] Such as Figure 2 to Figure 10 As shown, the gas and dust explosion and explosion suppression experimental system applicable to various optical diagnostic methods includes explosion pipes, vacuum system, gas distribution system, multiple powder spraying systems, ignition system, planar laser induced fluorescence system and main control system;

[0050] The explosion pipeline includes multiple pipeline units. The cross section of the pipeline unit is square. The bottom surface and skeleton of the pipeline unit are all made of steel to form a steel skeleton 11. Glass windows 12 are set on three sides. The transparent glass window 12 is made of high light transmittance. Imported fused silica, the length of each glass window 12 is not more than twice the width, so as to avoid deformation and shattering of the glass after being pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com