Active safeguard system and method for floating-roof oil tank

An oil storage tank, active safety technology, applied in containers, packaging, fire rescue and other directions, can solve the problems of aggravating floating roof load, large-scale burning of oil, difficult to clean, etc., to achieve reduced possibility, strong fluidity, and response time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

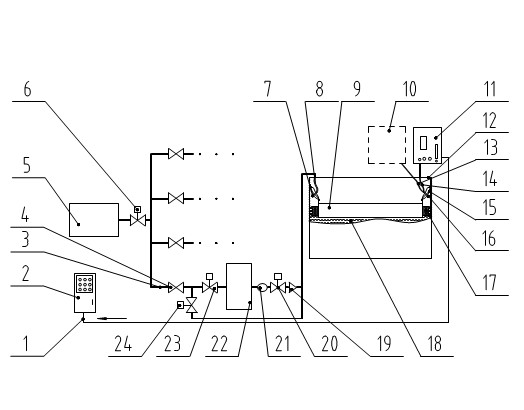

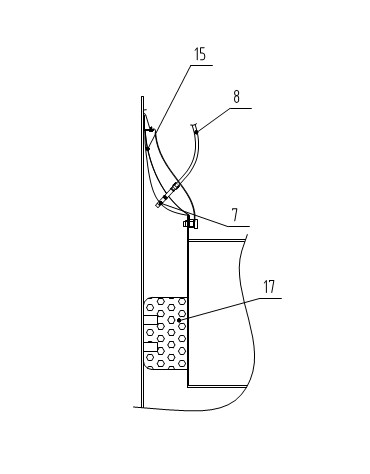

[0028] An active safety protection system for an external floating roof oil storage tank, such as figure 1 As shown, it includes: control line 1, control cabinet 2, pipeline 3, manual valve 4, carbon dioxide storage device 5, master control valve 6, carbon dioxide special nozzle 7, metal hose 8, outer floating roof 9, oil and gas filtration and recovery device 10. Gas detection and analysis device 11, oil storage tank 12, gas pipe for oil and gas recovery 13, gas pipe for detection and analysis 14, secondary seal 15, suction joint 16, primary seal 17, crude oil 18, one-way valve 19, regulating valve 20 , flow meter 21, carbon dioxide inerting device 22, inerting electric valve 23, fire extinguishing electric valve 24. in:

[0029] The active safety protection system of the external floating roof oil storage tank can control one or more oil storage tanks 12, and arrange the control cabinet 2 in a reasonable position for manual operation. The equipment involved is remotely con...

Embodiment 2

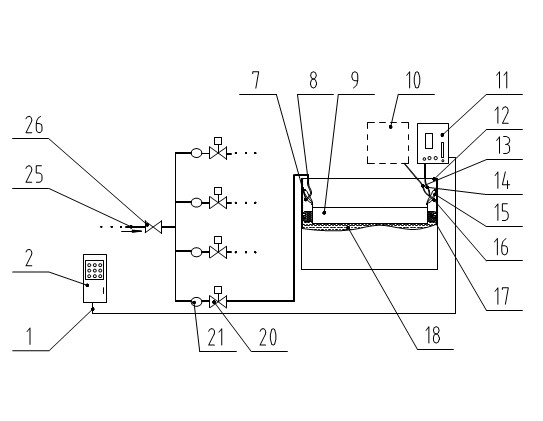

[0036] An active safety protection system for an external floating roof oil storage tank, such as figure 2 As shown, the difference from Embodiment 1 is that the pipeline 3, manual valve 4, carbon dioxide storage device 5, master control valve 6, check valve 19, carbon dioxide inerting device 22, inerting electric motor Valve 23 and fire extinguishing electric valve 24, and increased external carbon dioxide gas pipeline 25, external carbon dioxide pipeline valve 26. Embodiment 2 does not provide carbon dioxide gas from the carbon dioxide storage device 5 and the carbon dioxide inerting device 22, but uses the carbon dioxide gas generated in other processes, and transports it to the external floating roof through the external carbon dioxide gas pipeline 25 and the external carbon dioxide pipeline valve 26 The annular space between the primary and secondary seals of type petroleum storage tank 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com