High-speed railway hollow module cutting structure of plateau multi-year frozen soil area

A technology for high-speed railways and permafrost areas, applied in infrastructure engineering, roads, soil protection, etc., can solve problems such as strength decline, permafrost thawing, thawing, etc., to achieve environmental protection, prevent soil erosion, reduce Effect of small additional stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in combination with specific embodiments.

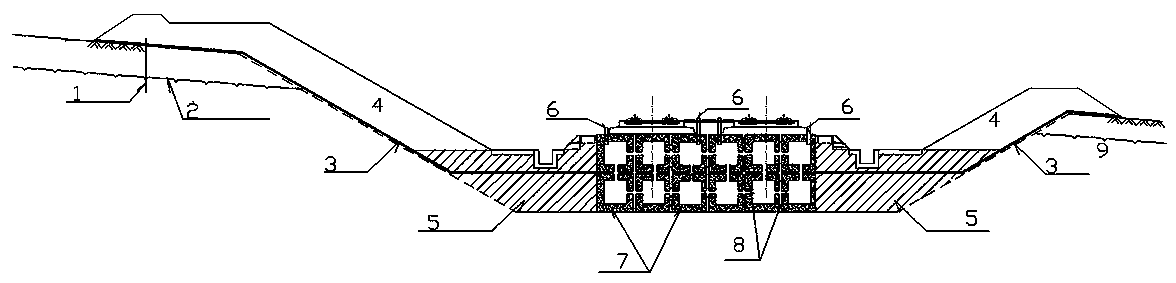

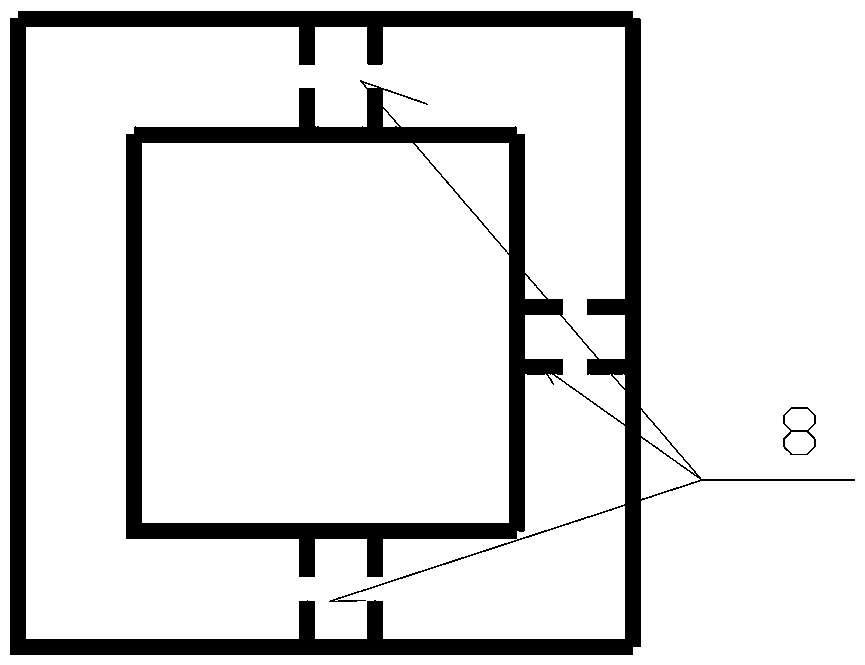

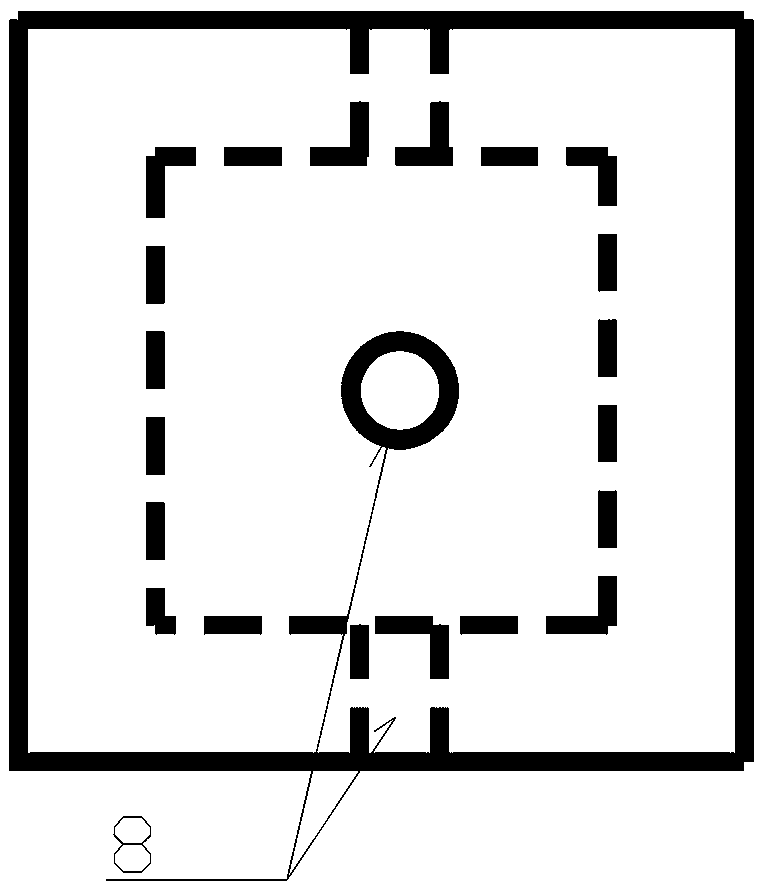

[0034] The present invention relates to a hollow module cutting structure for high-speed railways in plateau permafrost regions. Hollow modules 7 are laid in the cutting, and the layers are vertically and closely arranged in rows as the bearing foundation of the track slab; the hollow modules 7 are cuboid or cube. Hollow structure, in which two symmetrical surfaces are open, and ventilation openings 8 are reserved on the remaining surfaces, which are correspondingly connected when docking with adjacent modules.

[0035] When the hollow module 7 is assembled, the open surface is along the line direction, the rows and columns are aligned, the bottom surface is smooth, and the ventilation openings 8 of the adjacent modules are facing. The top surface of the hollow module 7 on the upper floor is provided with a vertical ventilation pipe 6, which communicates the interior of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com