Carbon dioxide fracturing device

A carbon dioxide and cracker technology, which is applied in blasting and other directions, can solve problems affecting production safety and economic losses, and achieve the effects of reducing labor, short throwing distance, and easy control of blasting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

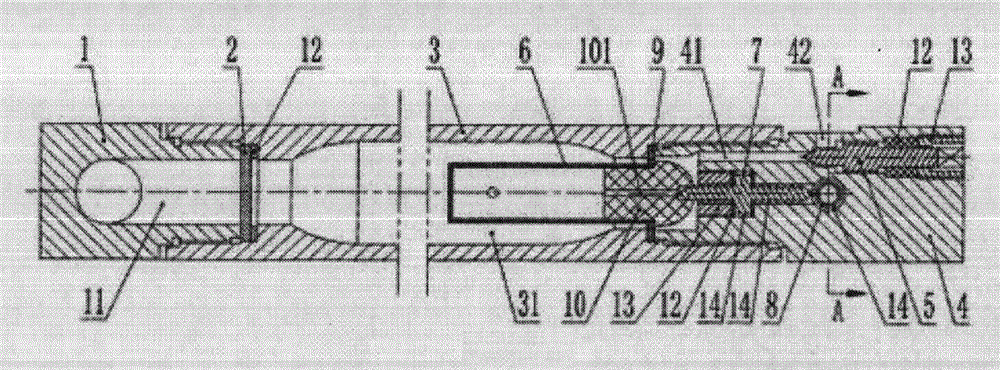

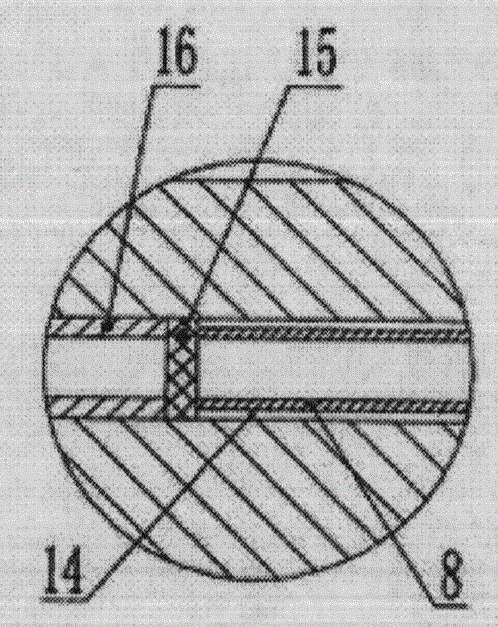

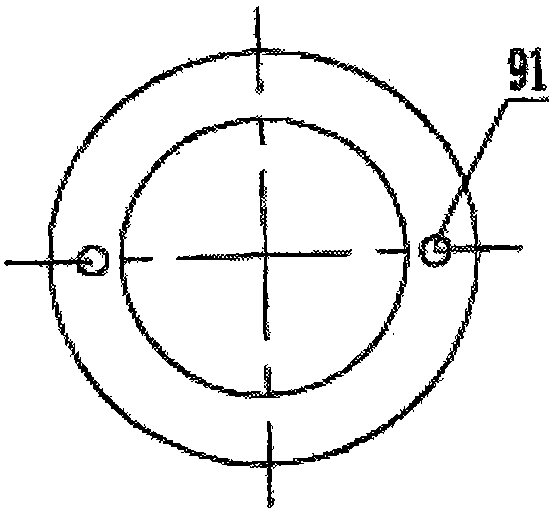

[0024] like figure 1 , figure 2 , image 3 As shown, the carbon dioxide cracker of this embodiment includes an energy-discharging head 1, a constant-pressure energy-relieving piece 2, a main pipe 3 and a filling head 4, and the energy-discharging head 1 and the filling head 4 are respectively screwed on the two ends of the main pipe 3 , the filling head 4 is provided with a filling channel 41 leading to the filling chamber 31 of the main pipe 3 and a thimble 5 for opening and closing the filling channel 41, and the energy-discharging head 1 is provided with an energy-discharging channel 11. One end leads to the filling chamber 31 of the main pipe 3, the other end leads to the outside of the carbon dioxide cracker, and the end of the energy release channel leading to the outside of the carbon dioxide cracker has several energy release holes facing different directions. The energy channel 11 and the filling chamber 31 of the main pipe 3 are sealed with a constant pressure ene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com