Static pressure, static pressure bearing used for high speed precision machine tool principal axis

A technology of dynamic and static pressure bearing and precision machine tool, applied in the direction of shaft and bearing, bearing, mechanical equipment, etc., can solve the problems of low air film rigidity, poor anti-overload ability, limited spindle speed, etc., to achieve high rigidity, excellent performance, design clever effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

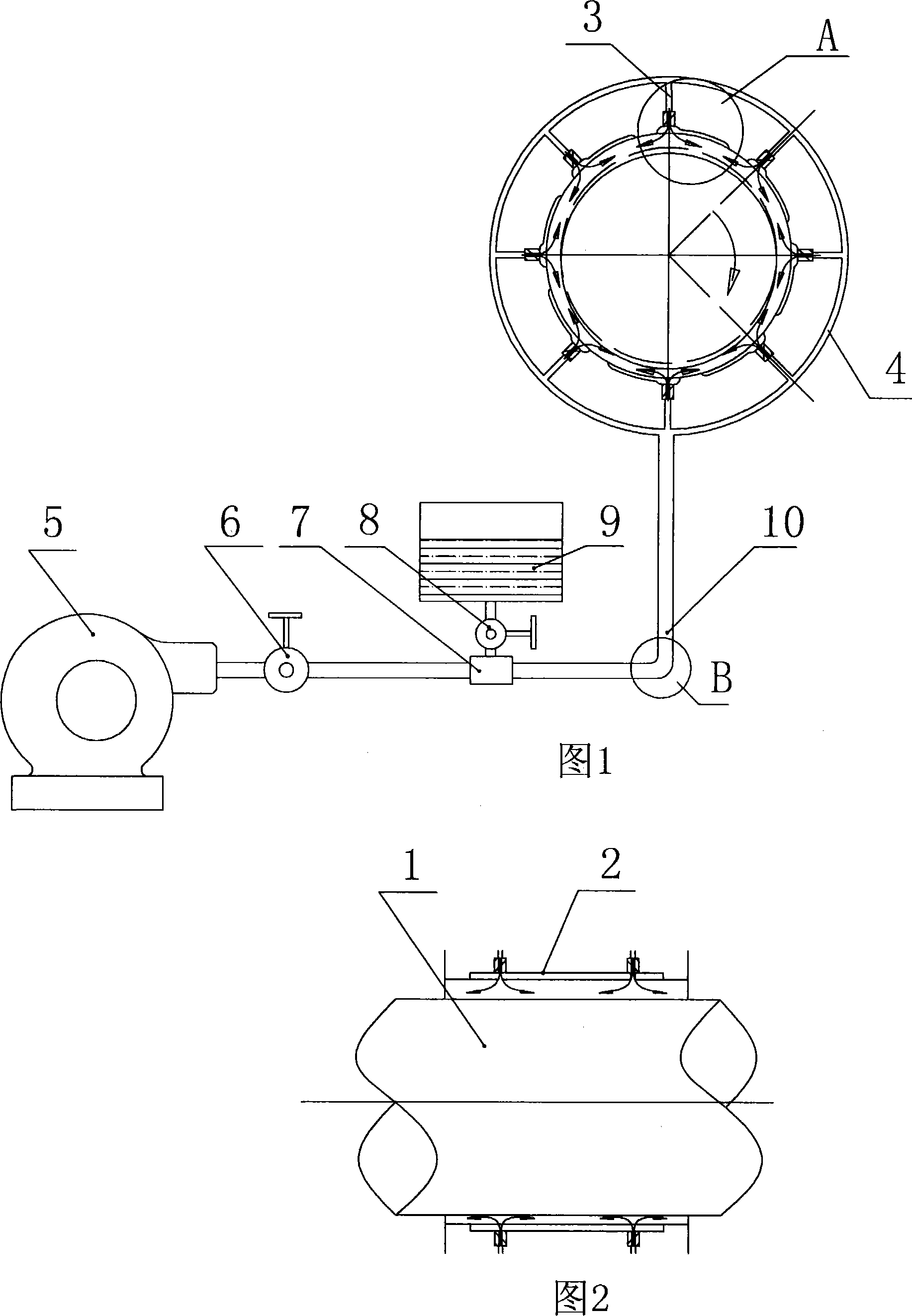

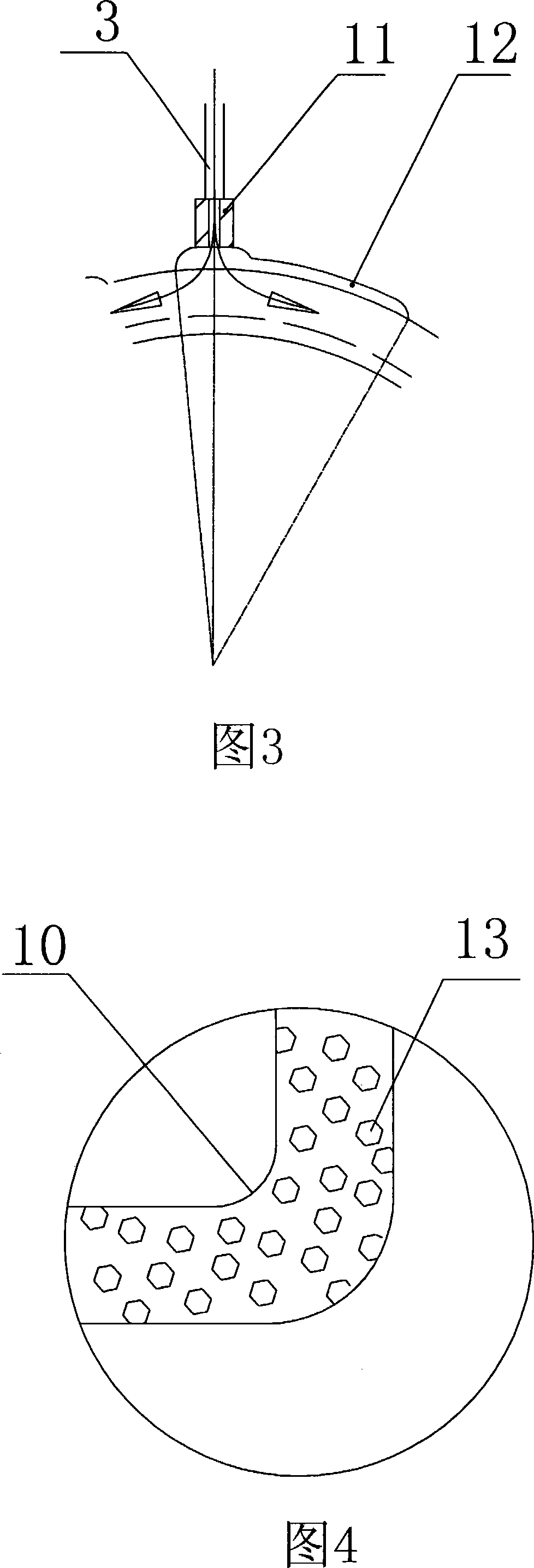

[0023] The schematic diagram of the structure of the present invention is shown in Figure 1, including a main shaft 1 and a bearing 2, wherein the bearing 2 is provided with a number of hydrostatic oil chambers 12 on the surface opposite to the main shaft 1, and each hydrostatic oil chamber 12 passes through the bearing restrictor respectively. 11 communicates with each lubricating point pipeline 3, and each lubricating point pipeline 3 is connected with the oil-air two-phase fluid lubrication supply system through the bearing main pipeline 4.

[0024] In this embodiment, the above-mentioned oil-gas two-phase fluid lubrication supply system includes an air compressor 5, an air pressure regulating valve 6, an oil atomization mixing valve 7, an oil flow regulating valve 8, a lubricating oil tank 9, and an oil-gas delivery pipeline 10, wherein the gas output port of the air compressor 5 is connected to the oil atomization mixing valve 7 through the air pressure regulating valve 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com