Lignite drying and carbonization quality-improving tower with reciprocating and turning-back rolling bed

A dry distillation and drying technology, which is applied in special forms of dry distillation, transmission devices, petroleum industry, etc., can solve the problems of low gas-solid heat transfer efficiency, dusty gas explosion, uneven coal seam temperature, etc., achieve high metal utilization rate, prevent coal lumps, etc. The effect of bursting and coal seam temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

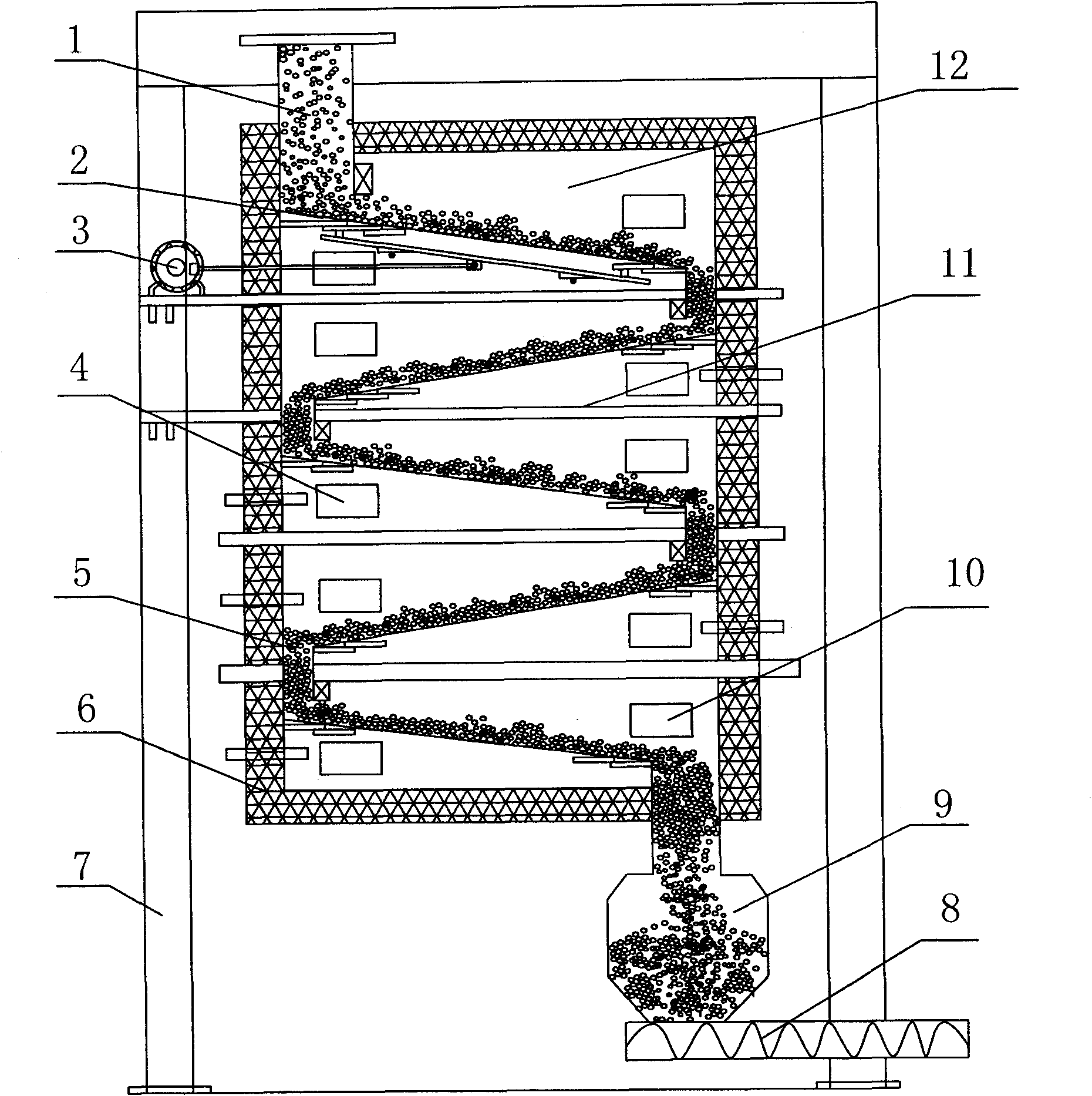

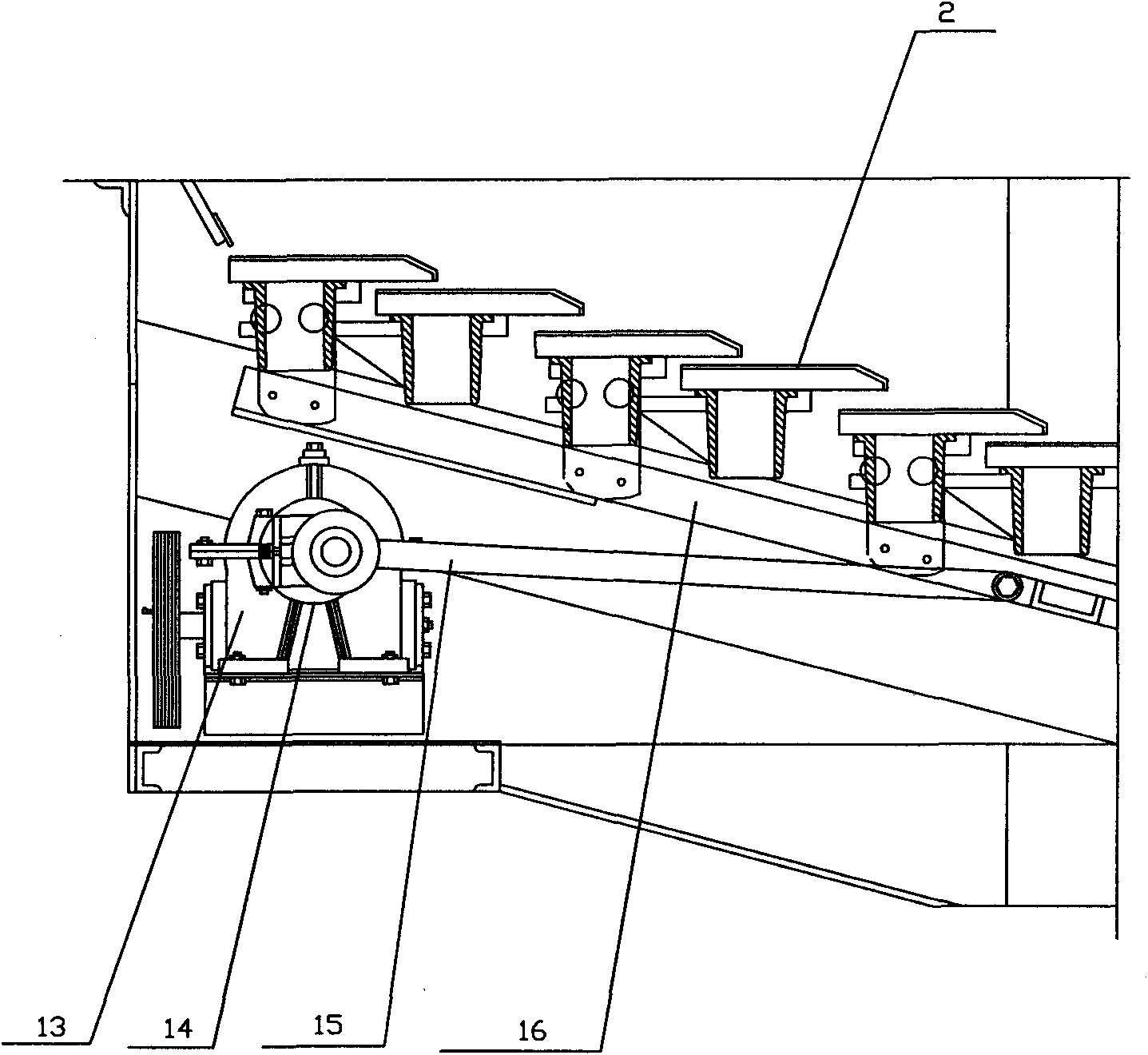

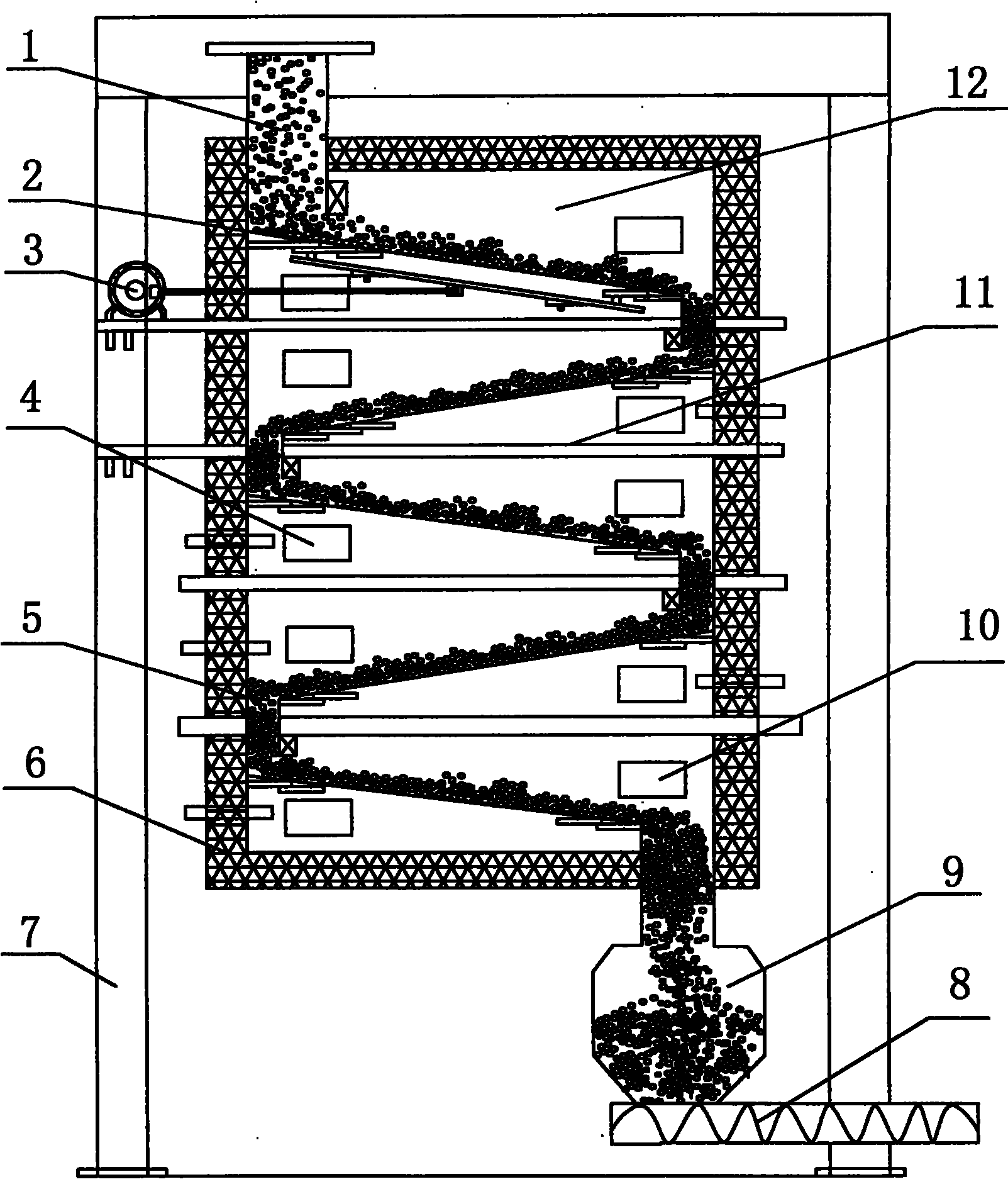

[0032] see figure 1 , the tower body 7 of the reciprocating rolling bed lignite drying and distillation upgrading tower described in this embodiment is a vertical structure, and the tower body 7 is provided with a drying and carbonization reaction room 12 surrounded by a furnace lining 6, and the drying and carbonization reaction room 12 There is a coal drop pipe 1 on the top, and the space is divided into a multi-layer drying room and a multi-layer retort room from top to bottom, and each drying room and retort room is equipped with an air inlet 4 for the desiccant or retort to enter and exit. The air outlet 10, the layer ratio between the drying room and the retort room depends on the coal quality parameters; the reciprocating grate 2 arranged obliquely is installed in the drying room and the retort room, and the inclination direction of each recipr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com