Explosion limit determining device and determining method

A technology of explosion limit and measuring instrument, which is applied in the direction of material explosion, can solve the problems of large error and inability to obtain the gas explosion limit, and achieve the effect of ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

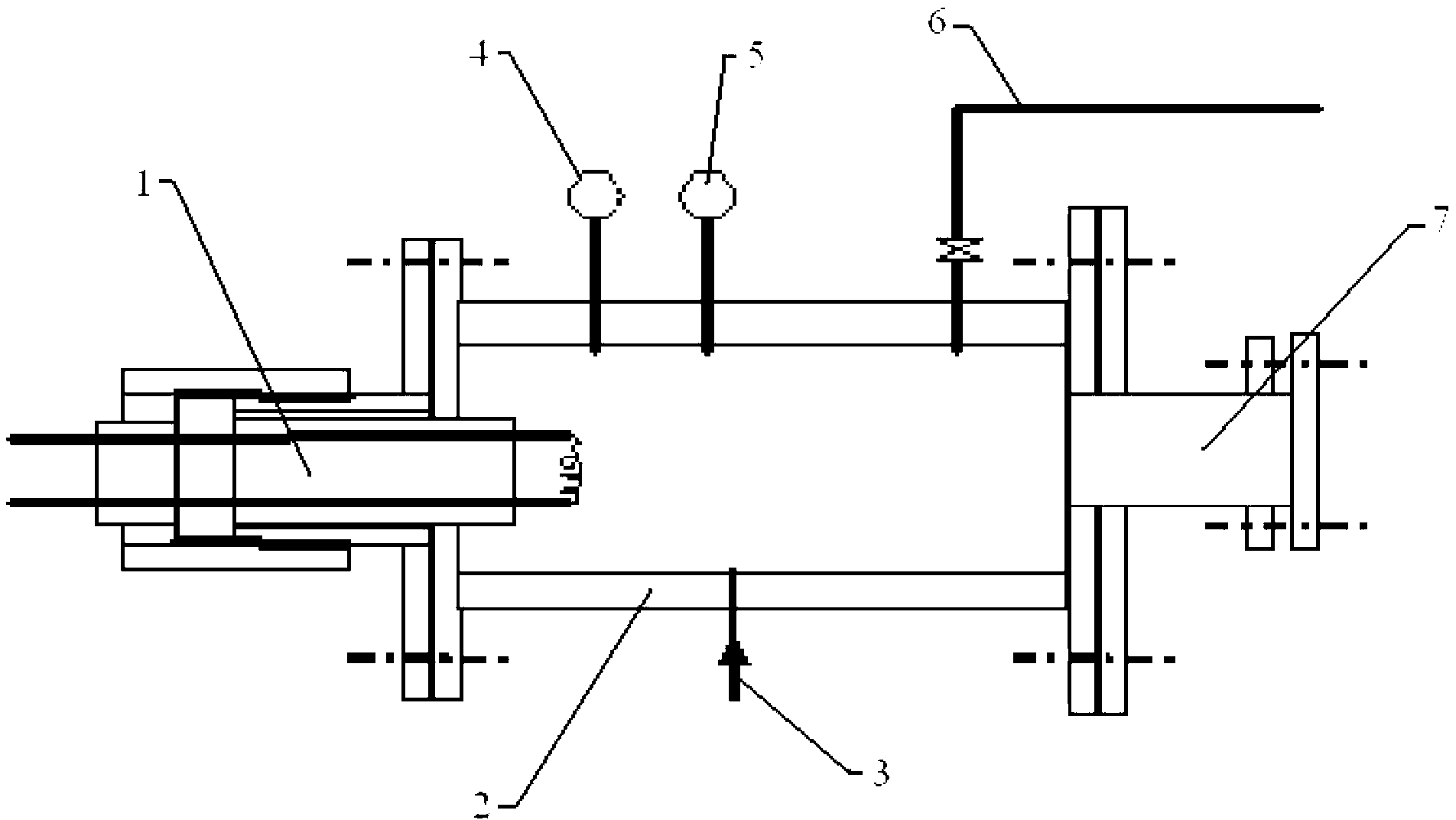

[0019] see figure 1 As shown, an explosion limit tester includes an ignition device 1, a pressure vessel 2, an air inlet 3, a temperature measurement port 4, a pressure measurement port 5, a vent port 6 and an observation port 7; the ignition device 1 is embedded and set In the pressure-resistant container 2, the pressure-resistant container 2 is provided with a heating and heat preservation system (not shown in the figure), an air inlet 3, a temperature measuring port 4, a pressure measuring port 5, a venting port 6 and an observation port 7.

[0020] The ignition device 1 adopts an AC furnace wire.

[0021] The pressure vessel 2 is made of stainless steel, and the design pressure is greater than 40MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com