Combustible gas explosion limit test system in non-standard state

A technology of gas explosion and limit testing, which is applied in the direction of analyzing materials and instruments, can solve the problem that the value cannot accurately reflect the working conditions of combustible gas, and achieve the effects of preventing major explosion accidents, high degree of automation, and significant social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0026] Such as Figure 1-5 shown.

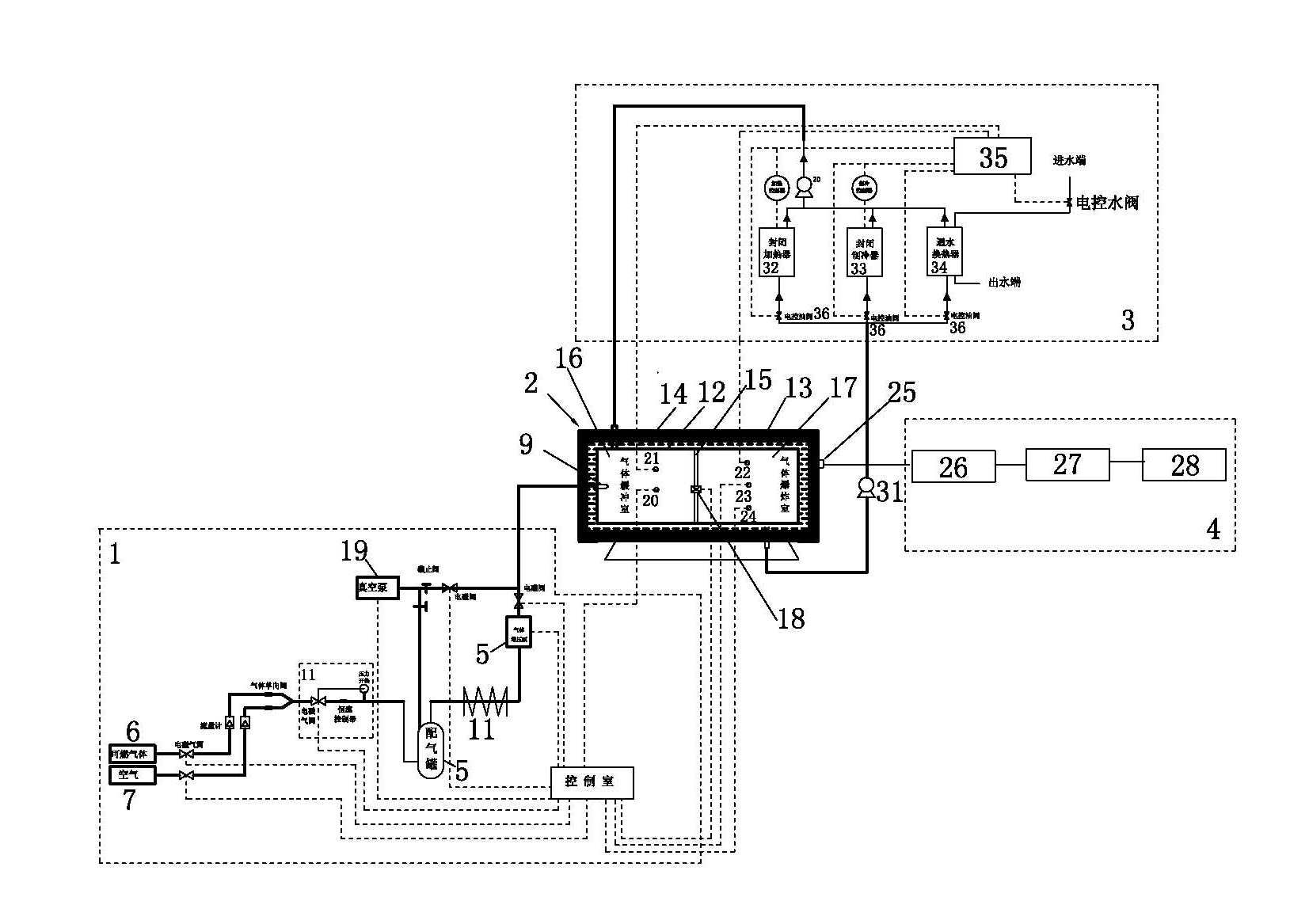

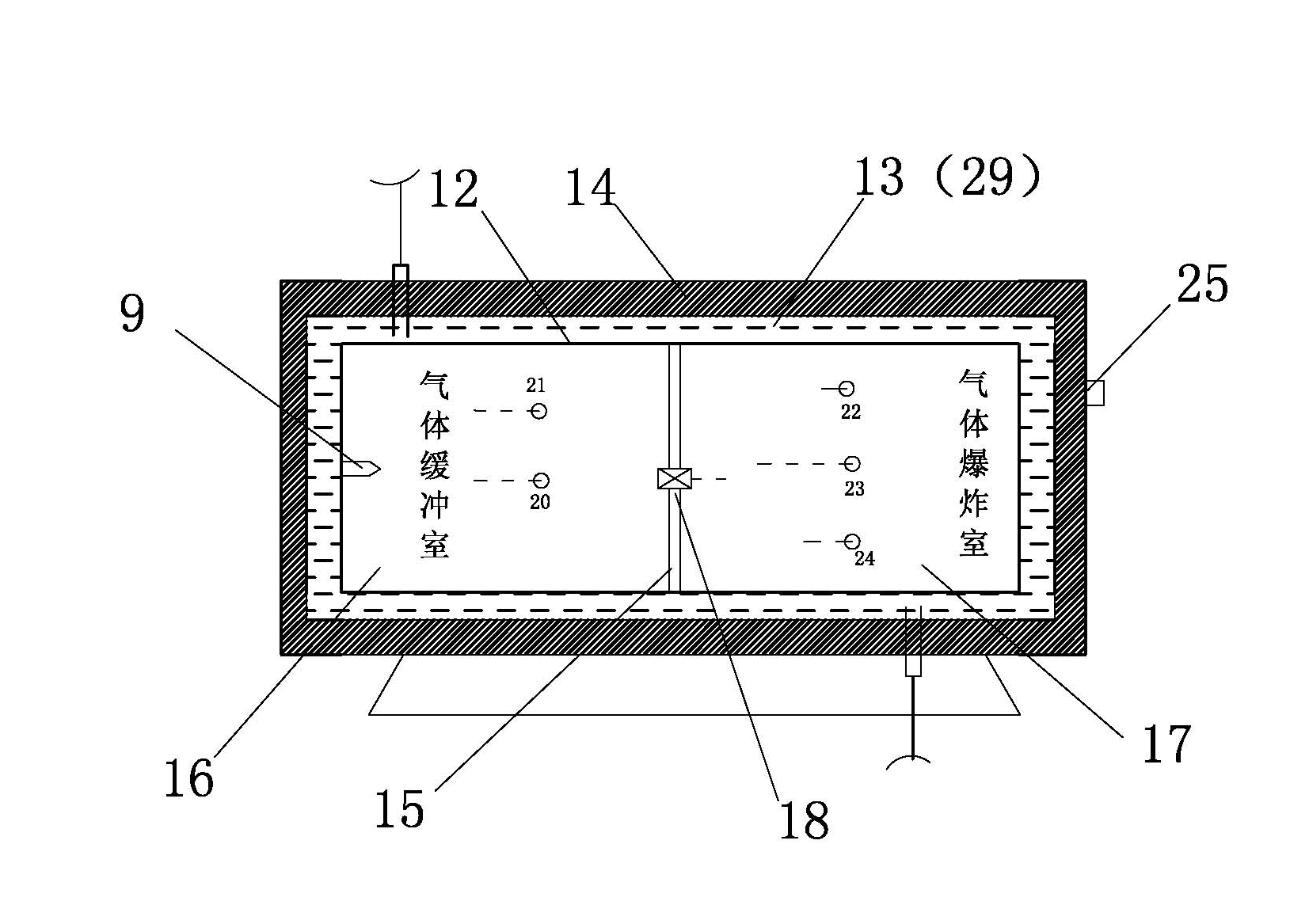

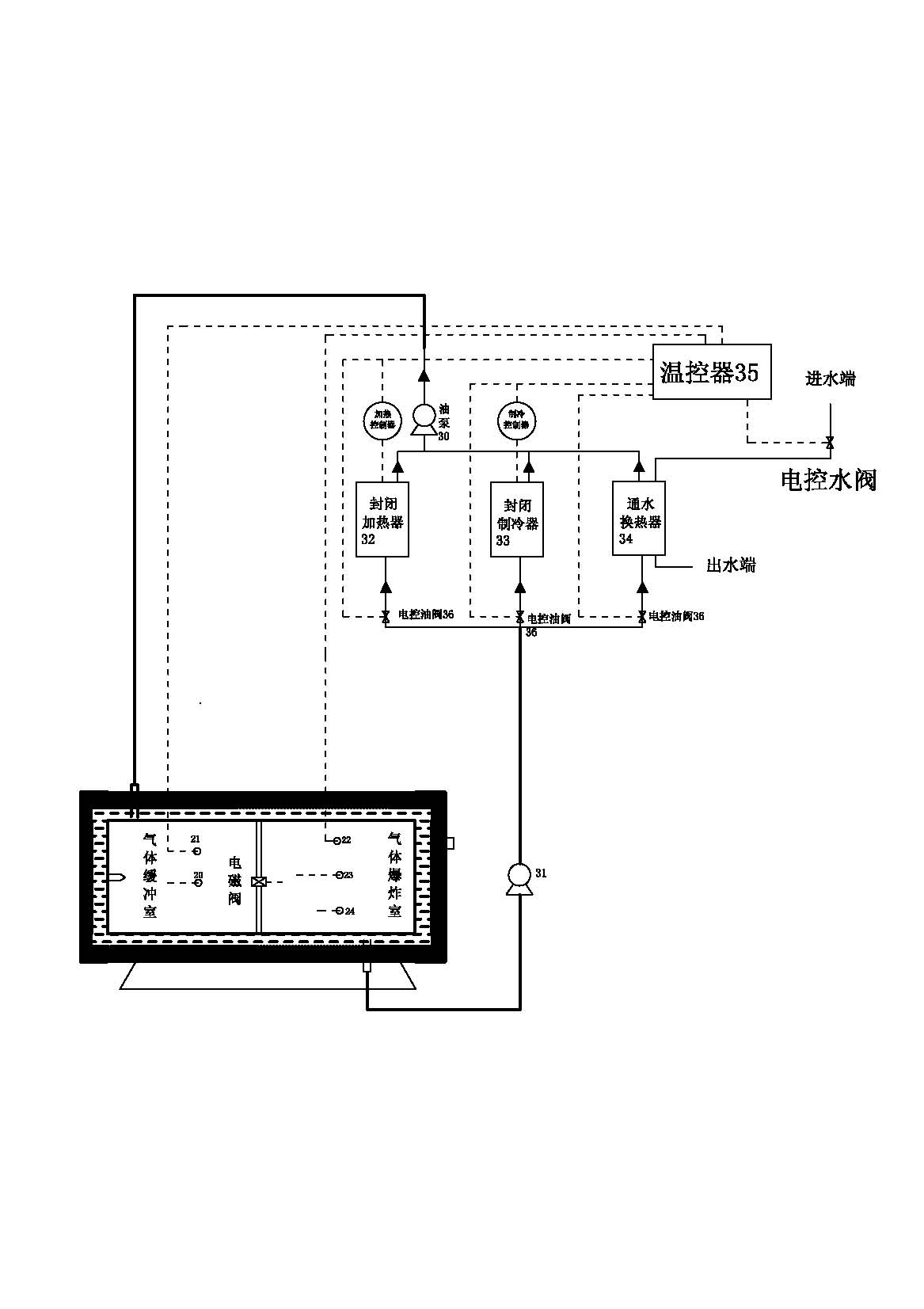

[0027] A combustible gas explosion limit test system in a non-standard state, which is mainly composed of: a gas distribution device 1, an explosion device 2, a temperature control device 3 and a data acquisition and processing device 4, such as figure 1 As shown, the gas distribution device 1 (such as Figure 4 As shown) includes gas distribution tank 5, the input end of gas distribution tank 5 is respectively connected with combustible gas source 6 (gas cylinder or directly connected with gas generating device) and gas distribution gas source 7 (can be clean air or other inert gas), in order to accurately control the mixing amount of the combustible gas and the distributed gas (air), a gas distribution device 11 (model can be GH-1) can be installed in front of the input end of the gas distribution tank 5, the gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com