Power battery pack assembly structure of all-electric vehicle

A technology for power battery packs and pure electric vehicles. It is applied in the direction of electric vehicles, secondary batteries, and structural parts. It can solve problems such as heavy weight of battery packs, high loads on front or rear axles, and limited space for power batteries. Reasonable design, reasonable structure layout, good effect of fixing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

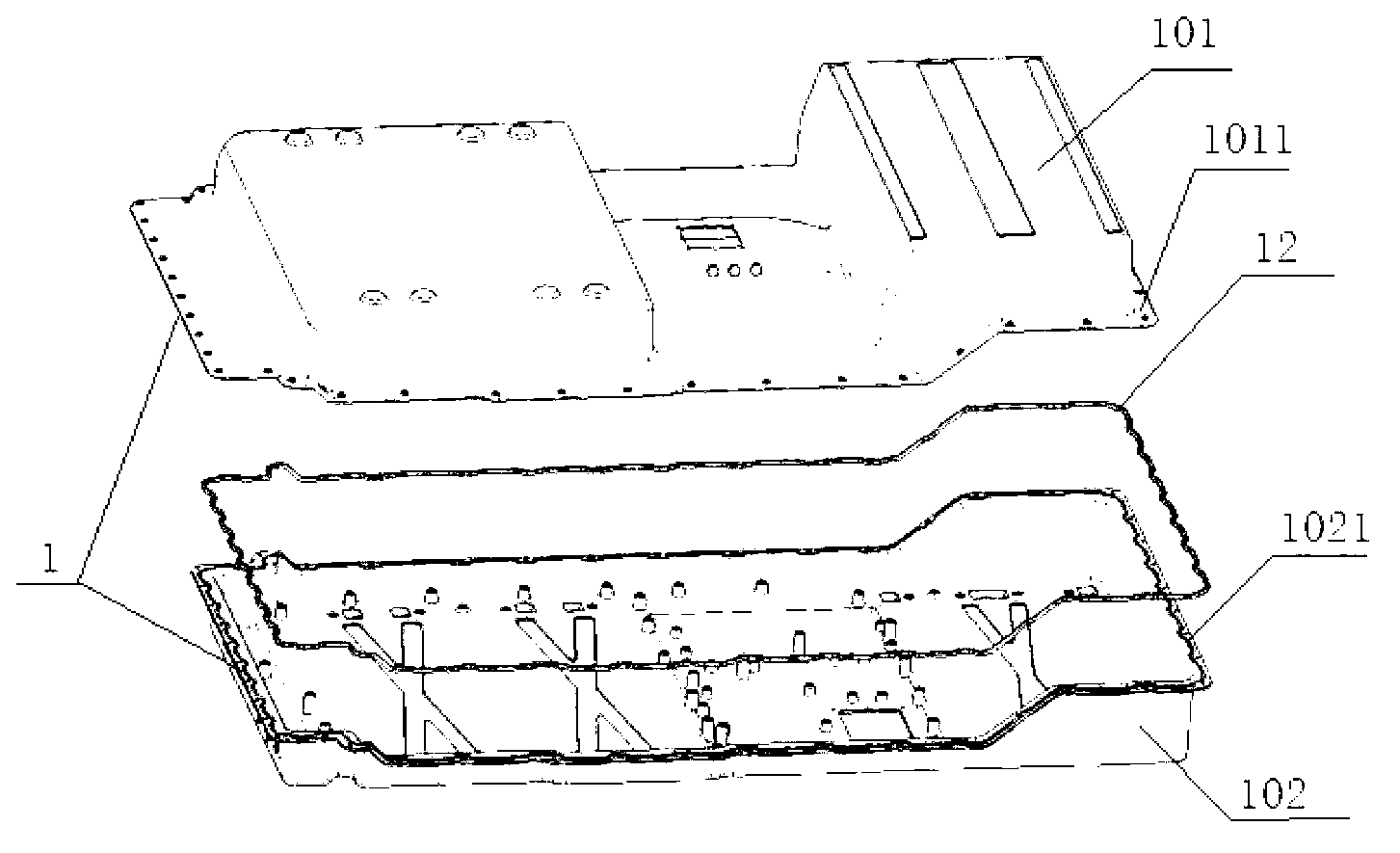

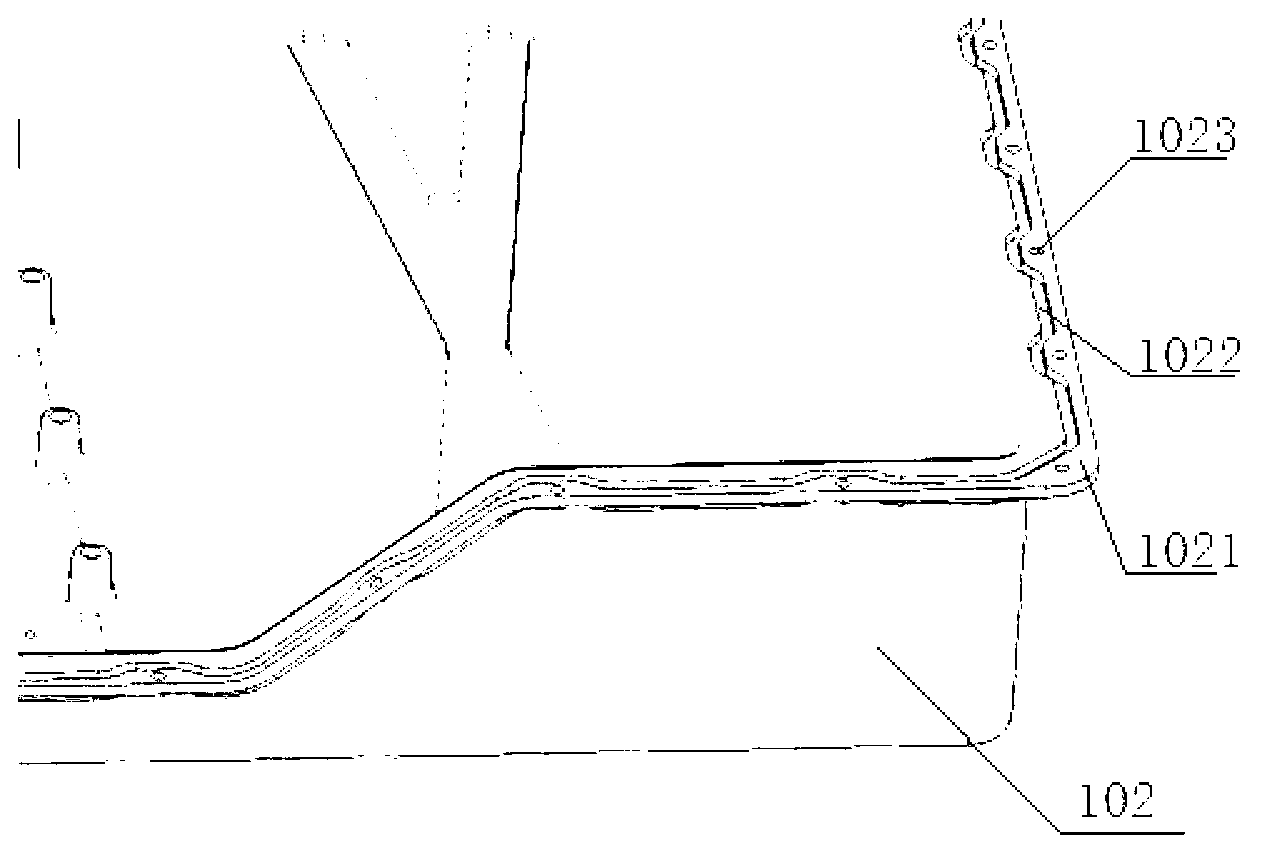

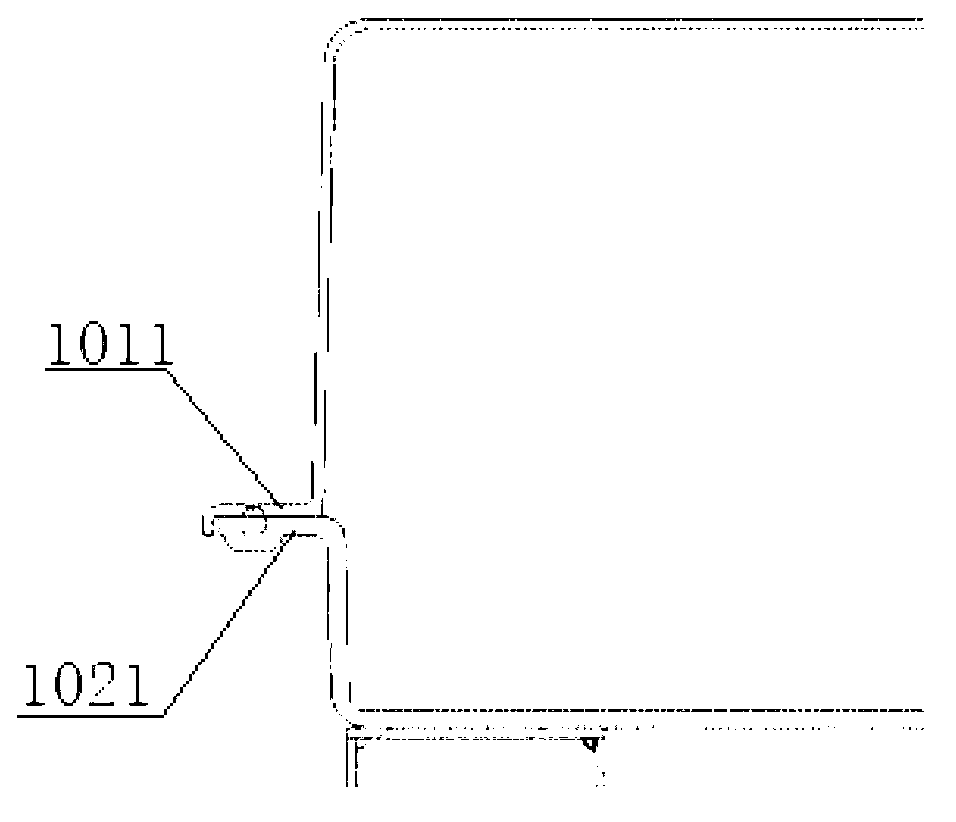

[0039] Such as figure 1 As shown, a pure electric vehicle power battery pack assembly structure includes a casing 1, the overall structural shape of the casing 1 is approximately a cuboid, and the casing 1 includes an upper casing 101 and a lower casing 102. The top surface of the housing 101 is stepped with two ends high and the middle low, and the top surface of the rear part of the upper housing 101 is higher than the top surface of the front part, the angle between the side wall of the upper housing 101 and the top surface of the upper housing 101 ≥91.5°, retaining an inclination angle of at least 1.5° is for molding and demoulding. The bottom of the upper shell 101 is open and the bottom edge is provided with an uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com