Movable acrylic stair mold

A stair mold and acrylic technology, used in molds, mold fixtures, mold auxiliary parts, etc., can solve the problems of long pouring and solidification cycle, increased mold production cost, non-recyclable multi-size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further description will be made below in conjunction with drawings and embodiments.

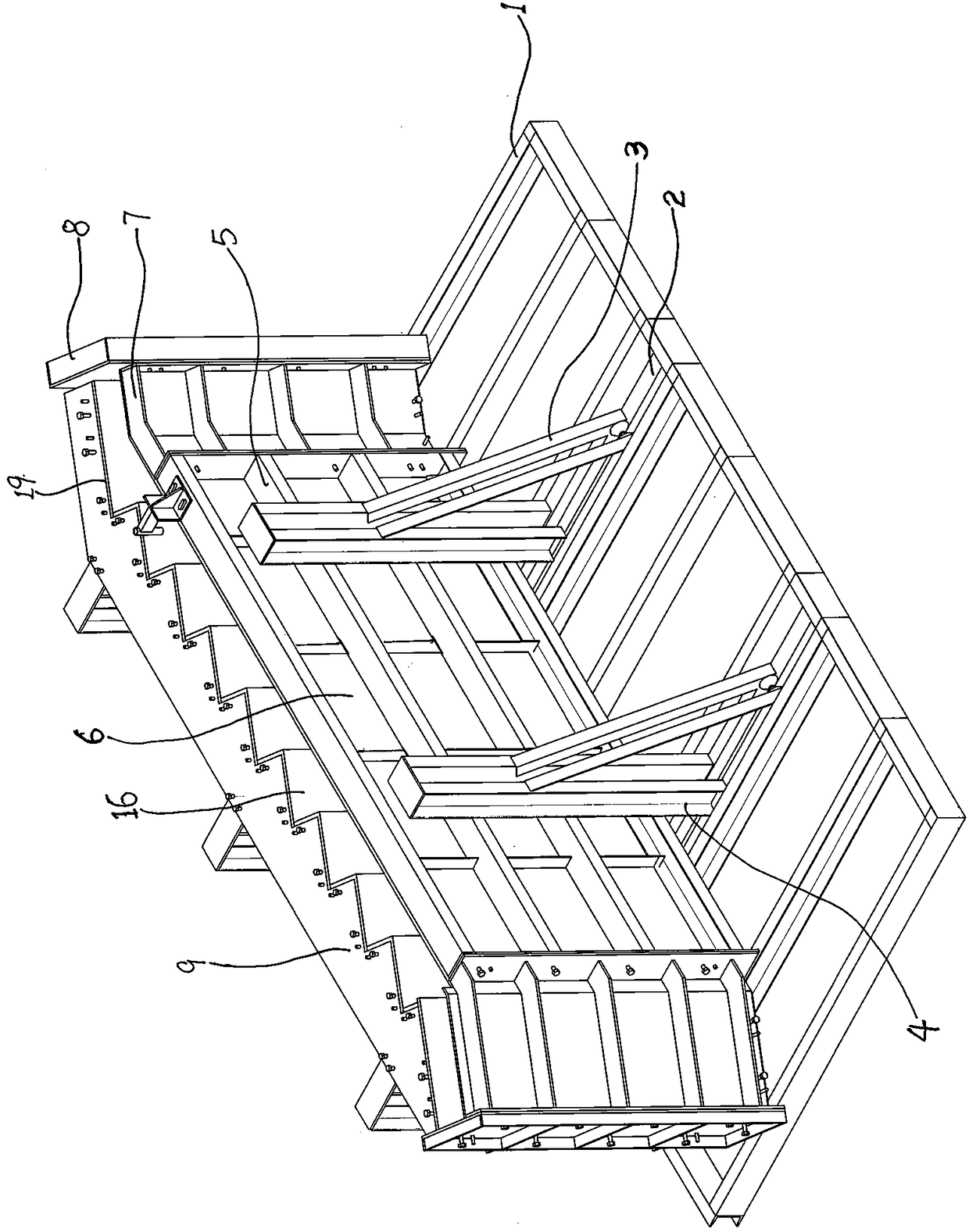

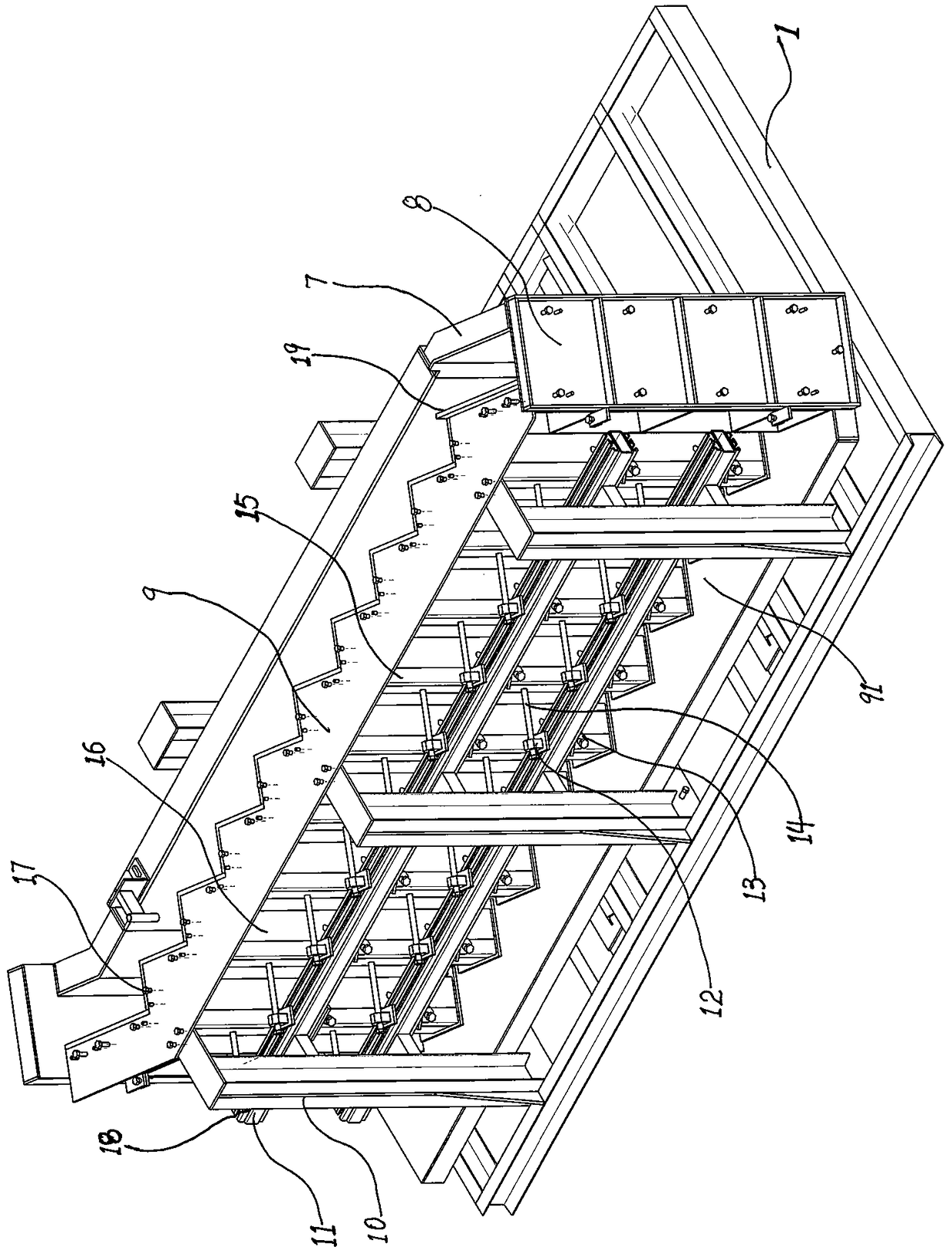

[0016] figure 1 , 2 As shown, a movable acrylic staircase mold includes a base 1, a back push chute 2, a back push inclined frame 3, a back push stand 4, a back frame 5, an acrylic back plate 6, a corner plate 7, and a head Plate 8, upper sawtooth positioning plate 9, lower sawtooth positioning plate 91, bracket 10, beam 11, upper adjustment seat 12, lower adjustment seat 13, adjustment bolt 14, L-shaped corner tube plate 15, acrylic panel 16, positioning pin 17.

[0017] A plurality of brackets 10 are vertically arranged on one side of the base 1 at even intervals along the length direction of the stairs, and a plurality of beams 11 are horizontally and parallelly arranged on the brackets 10. Slide grooves 18 are arranged on the upper and lower end faces of the beams 11, and a plurality of upper and lower The adjustment seats 12 and 13 are respectively arranged in the chute on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com