Diamond tool welding machine

A diamond tool and welding machine technology, applied in metal processing and other directions, can solve the problems of reducing the manufacturing cost of the welding machine, simplifying the control, difficult to automate welding, complex and other problems, and achieving the effects of simple structure, low production cost and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

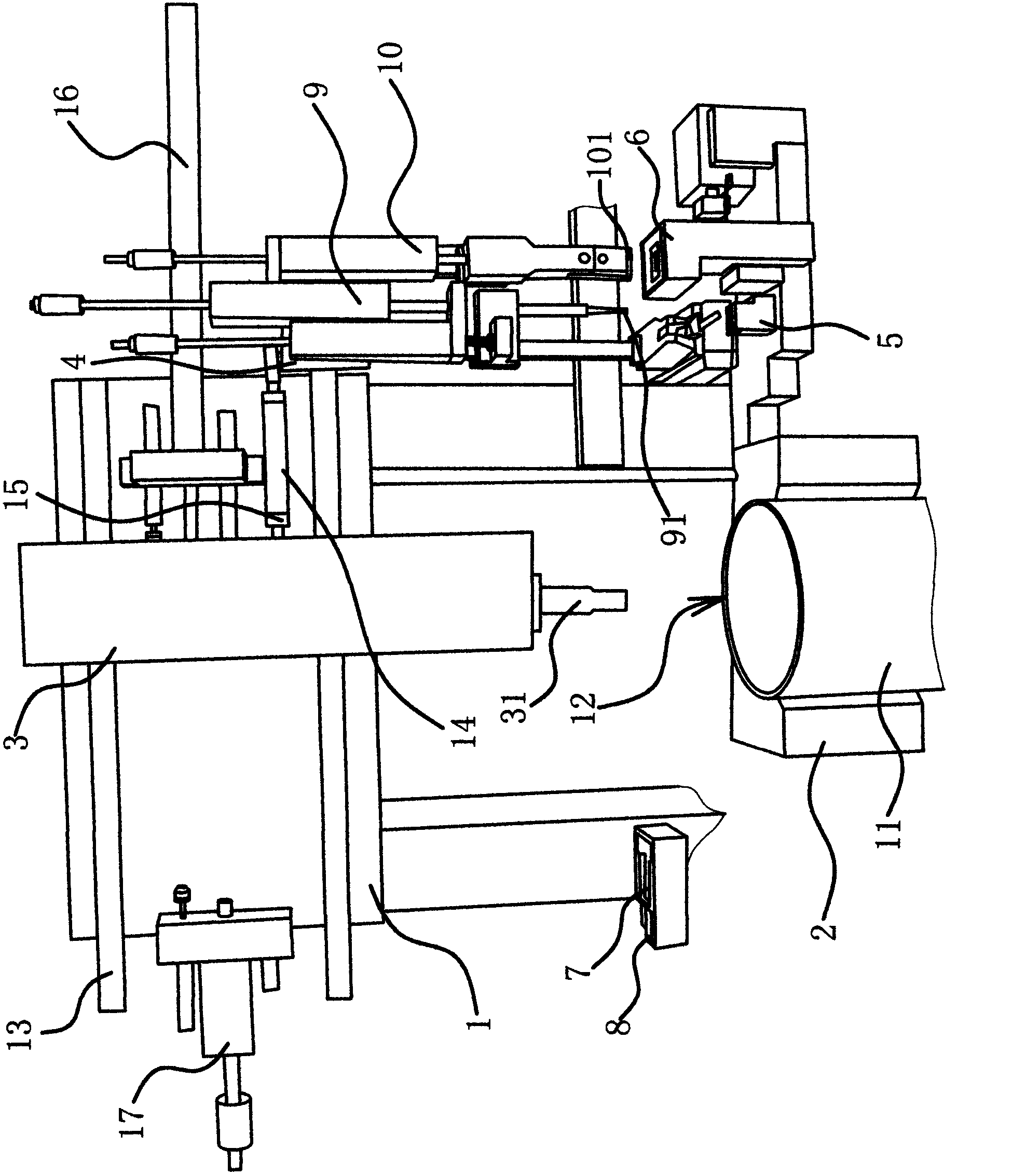

[0017] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0018] like figure 1 As shown, the diamond tool welding machine includes a frame 1, a positioning tool 2, a cutter head clamping device 3, a translation seat 4, an electrode holder 5, a dipping station 6, a dipping station 7, and a cutter head positioning seat 8. The solder suction chip device 9 and the glue dipping device 10.

[0019] Specifically, the positioning tool 2 is used to position the cutting tool base 11, such as the barrel positioning device in the thin-wall drill welding machine disclosed in Chinese patent literature [Application No.: 20101017363 3.4]. The positioning tooling 2 is fixed on the frame 1.

[0020] The cutter head clamping device 3 is located above the positioning tool 2 . A linear guide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com