Automatic air impermeability helium detector for square power batteries

A power battery, air tightness technology, applied in the field of square power battery leak detection equipment, can solve the problems of low efficiency, unstable production quality, easy pollution, etc., and achieve the effect of high efficiency, compact structure and perfect system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

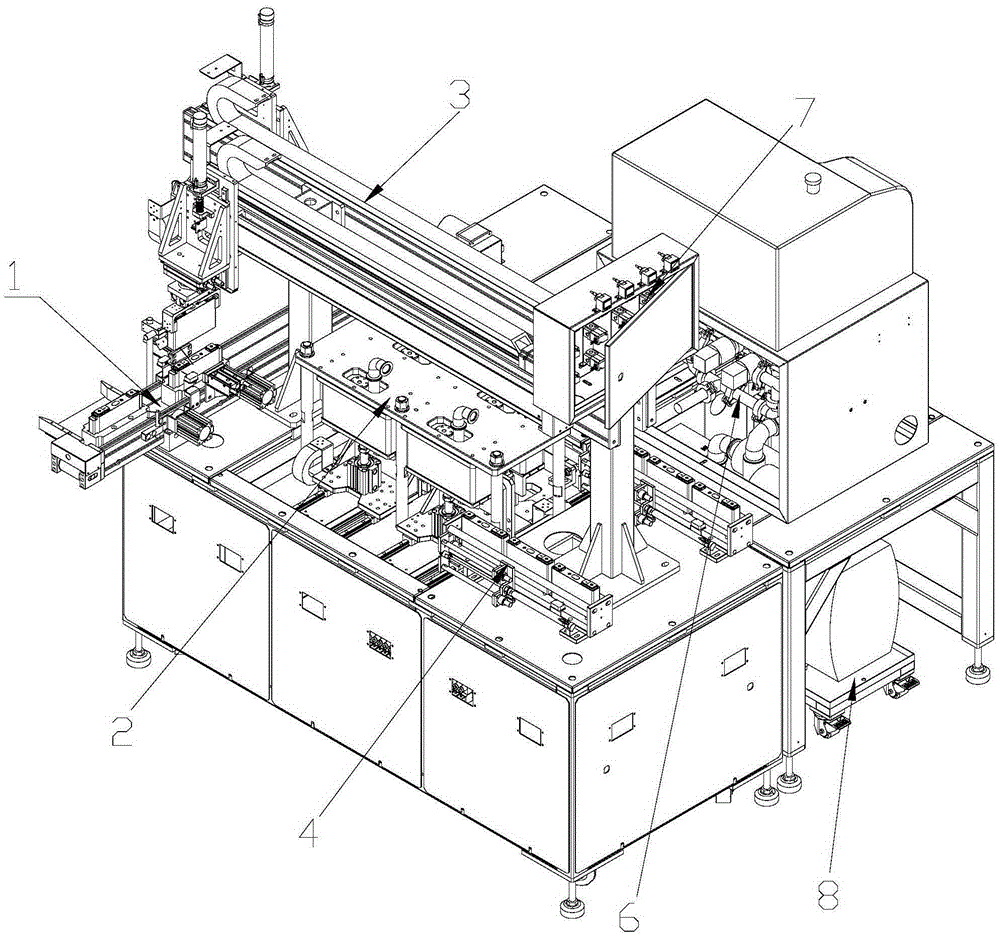

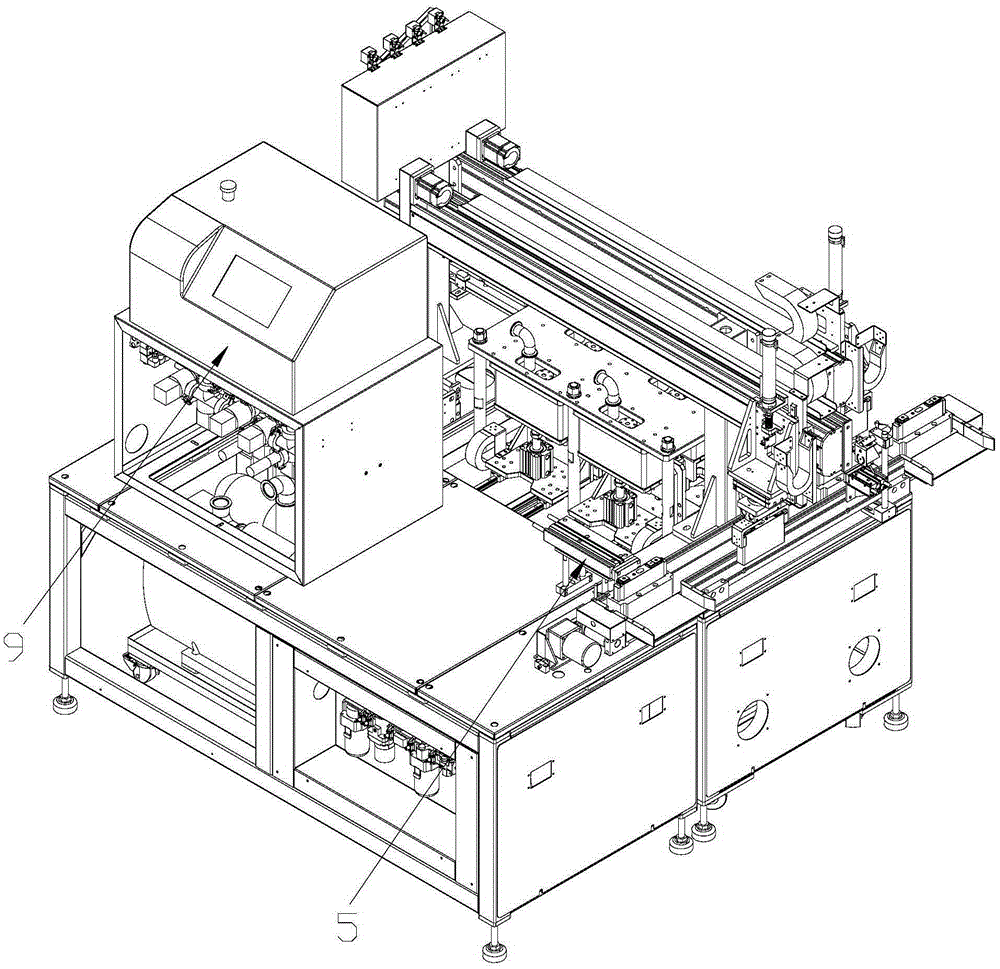

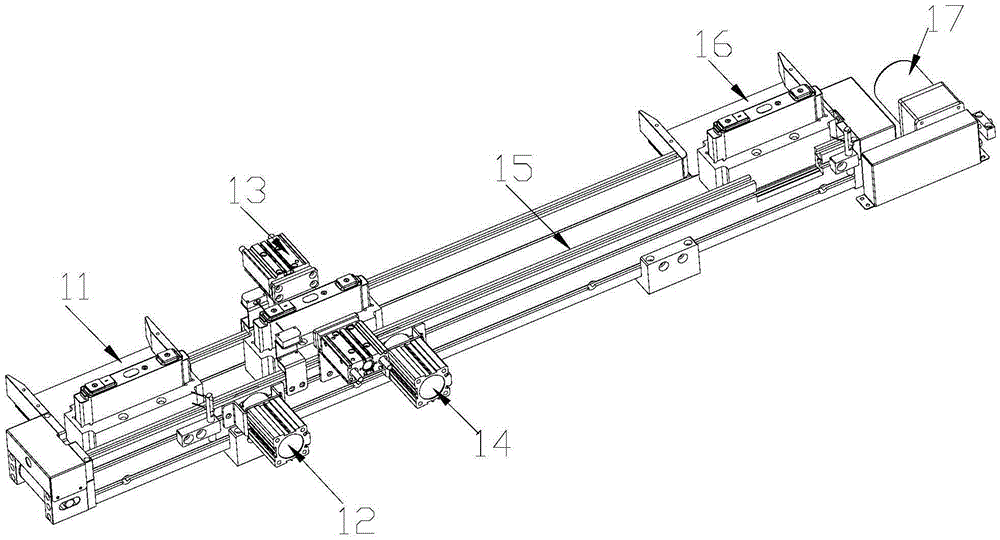

[0042] like Figure 1-12As shown, it shows a specific embodiment of the present invention; as shown in the figure, the automatic airtight helium inspection machine for a square power battery disclosed by the present invention, the square power battery is an aluminum shell cell; it includes a frame, a machine The rack is provided with a loading belt assembly 1, a helium detection test assembly 2, and a loading and unloading manipulator assembly 3; It includes the aluminum shell cell loading level 11 at the starting end, the aluminum shell cell discharge level 16 at the end, and the aluminum shell cell detection position set between the loading level and the discharge level;

[0043] As shown in the figure, the feeding manipulator assembly is used to grab the aluminum-cased battery cell on the feeding pull belt assembly to the cavity 23 in the helium test assembly 2, and to grab the aluminum-cased battery cell in the cavity 23 Grab it on the loading belt assembly 1 or in the NG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com