Multi-wire cutting device applied to block forming of silicon ingot

A multi-wire cutting, silicon ingot technology, applied in stone processing equipment, fine working devices, manufacturing tools, etc., can solve the problems of wasted labor costs, low cutting efficiency, manual adjustment of cutting positions, etc., to improve production efficiency, cutting Great effect and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

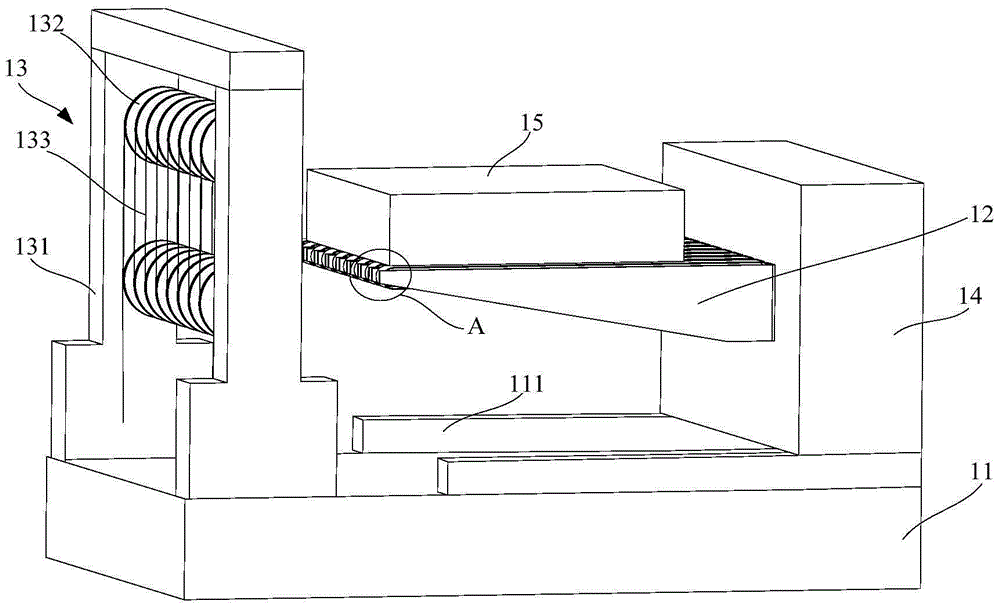

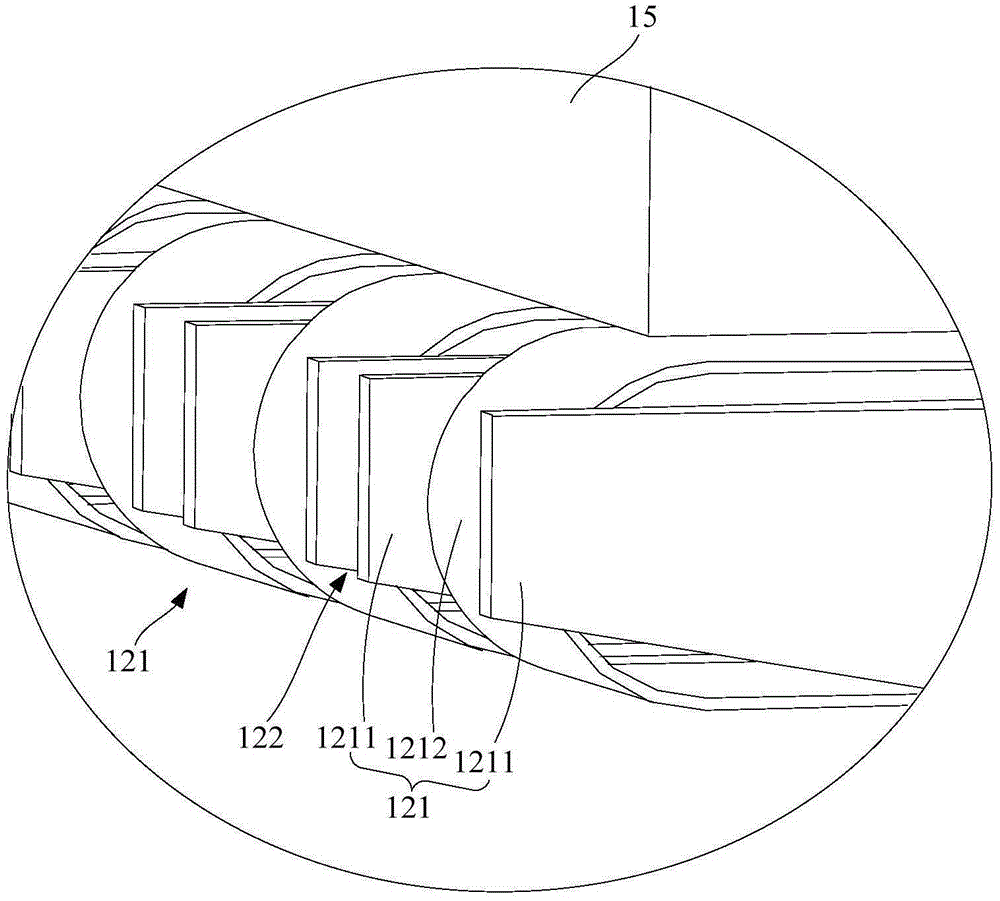

[0042] see figure 1 , is a schematic structural diagram of the first embodiment of the multi-wire cutting equipment applied to silicon ingot squaring according to the present invention. The invention provides a multi-wire cutting equipment applied to silicon ingot squaring, in particular to a multi-wire cutting equipment applied to a winding drum, a cutting roller, and a diamond wire wound on the winding drum and the cutting roller. Silicon ingots are square cut. Such as figure 1 As shown, the multi-wire cutting equipment applied to silicon ingot squaring according to the present invention includes a base 11 , a carrier table 12 for carrying a silicon ingot to be cut, and a cutting mechanism 13 .

[0043] A pair of sliding rails 111 are oppositely arranged on the base 11, and a carrying platform 12 is slidably arranged on the sliding rails 111, so that the carrying platform 12 and the cutting mechanism 13 can move relatively so that the cutting mechanism 13 can cut the silic...

no. 2 example

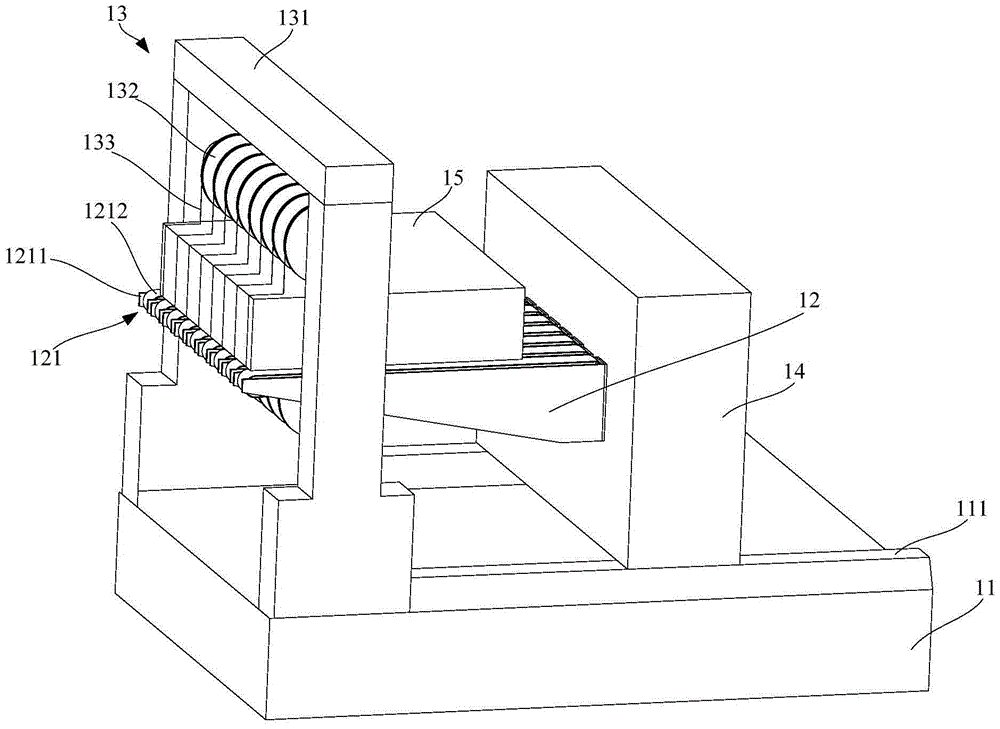

[0059] see Figure 8 , is a schematic structural diagram of the second embodiment of the multi-wire cutting equipment applied to silicon ingot squaring according to the present invention. Such as Figure 8 As shown, the multi-wire cutting equipment applied to silicon ingot squaring according to the present invention includes a base 11 , a carrier table 12 for carrying a silicon ingot to be cut, and a cutting mechanism 13 .

[0060] The difference between the multi-wire cutting equipment in the second embodiment and the multi-wire cutting equipment in the first embodiment is mainly reflected in: in the first embodiment, the method adopted is: the carrying platform 12 is slid on the slide rail 111' The cutting mechanism 13 is fixed on the base. In the second embodiment, the adopted method is: the carrying platform 12 is fixedly arranged on the base 11 and the cutting mechanism 13 is slidably arranged on the slide rail 111 ′.

[0061] In order to realize that the cutting mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com