Laser cutting machine

A laser cutting machine, cutting machine technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the cutting requirements that cannot meet the precision and quality of hard plate materials, serrated, and the cutting edge is not smooth enough, etc. Achieve high-quality cutting results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Further details will be given below in conjunction with the preferred embodiments shown in the accompanying drawings.

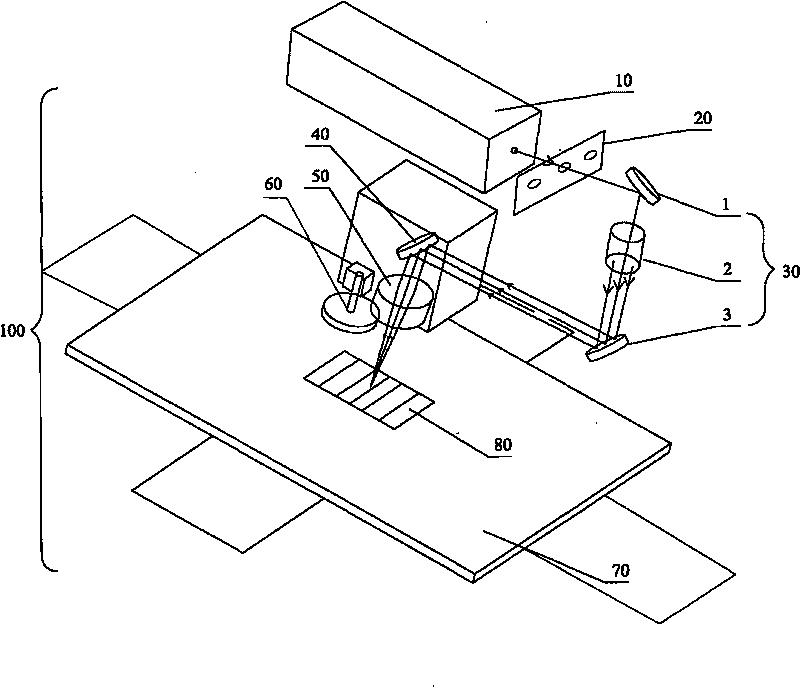

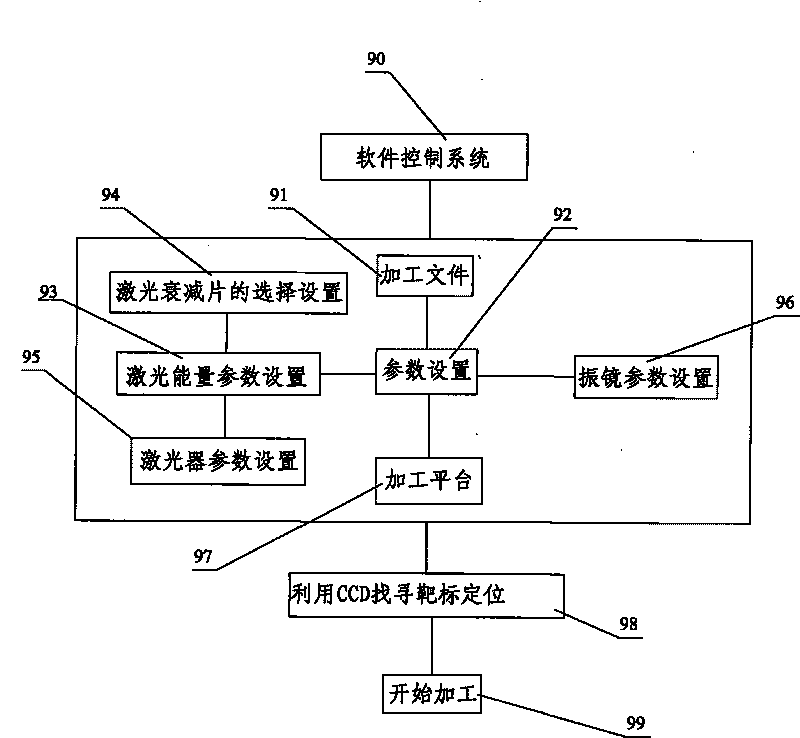

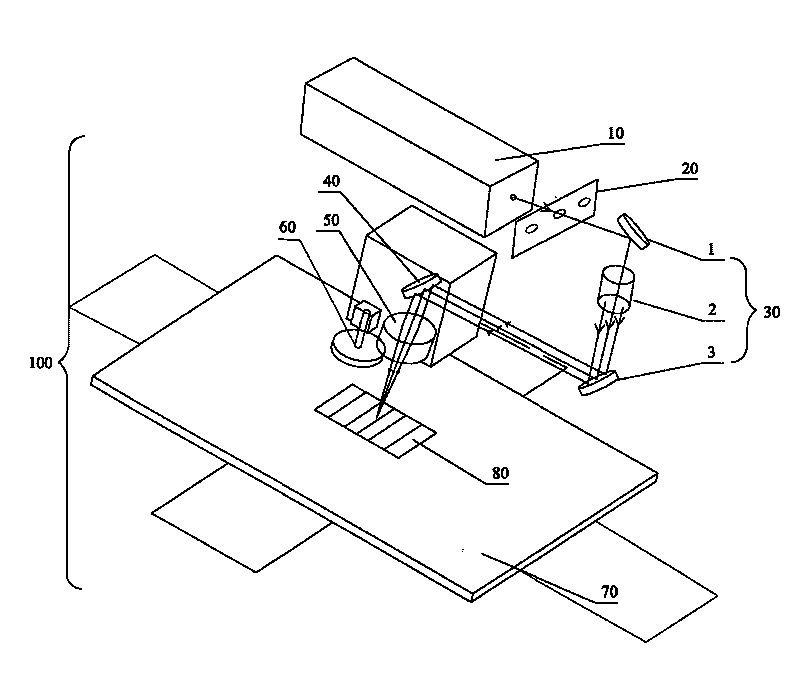

[0009] Such as figure 1 As shown, it is a schematic structural diagram of the laser cutting machine of the present invention. The laser cutting machine 100 of the present invention includes a laser 10, a laser energy selection system 20, an optical transmission system 30, a vibrating mirror scanning system 40, a focusing mirror 50, and a vacuum adsorption system 70. The CCD positioning system 60 is an optical positioning system; the optical transmission system 30 includes: a first reflector 1 , a beam expander 2 and a second reflector 3 . The laser emitted by the laser 10 according to the embodiment of the present invention has a wavelength of 490-580nm, preferably a green laser with a wavelength of 500-570nm, especially a green laser with a wavelength of 532nm. The laser beam emitted by the laser 10 first passes through a laser energy selection syste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com