Improved multi-line cutting device

A multi-line cutting and equipment technology, which is applied to stone processing equipment, fine working devices, manufacturing tools, etc., can solve the problems of increased sedimentation of cutting sand, difficulty in adapting to multi-line slicing, affecting cutting effect, etc. Sand ability, improve dispersion and take away effect, improve cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with specific embodiments.

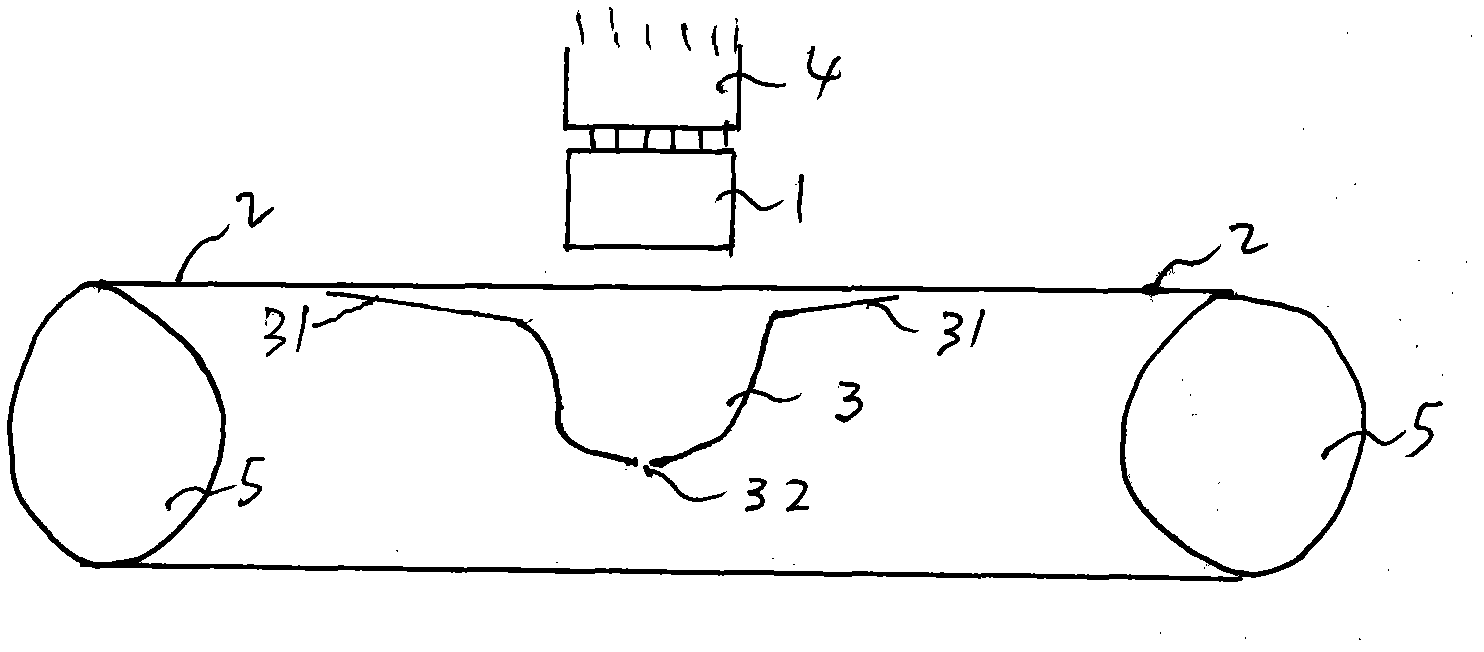

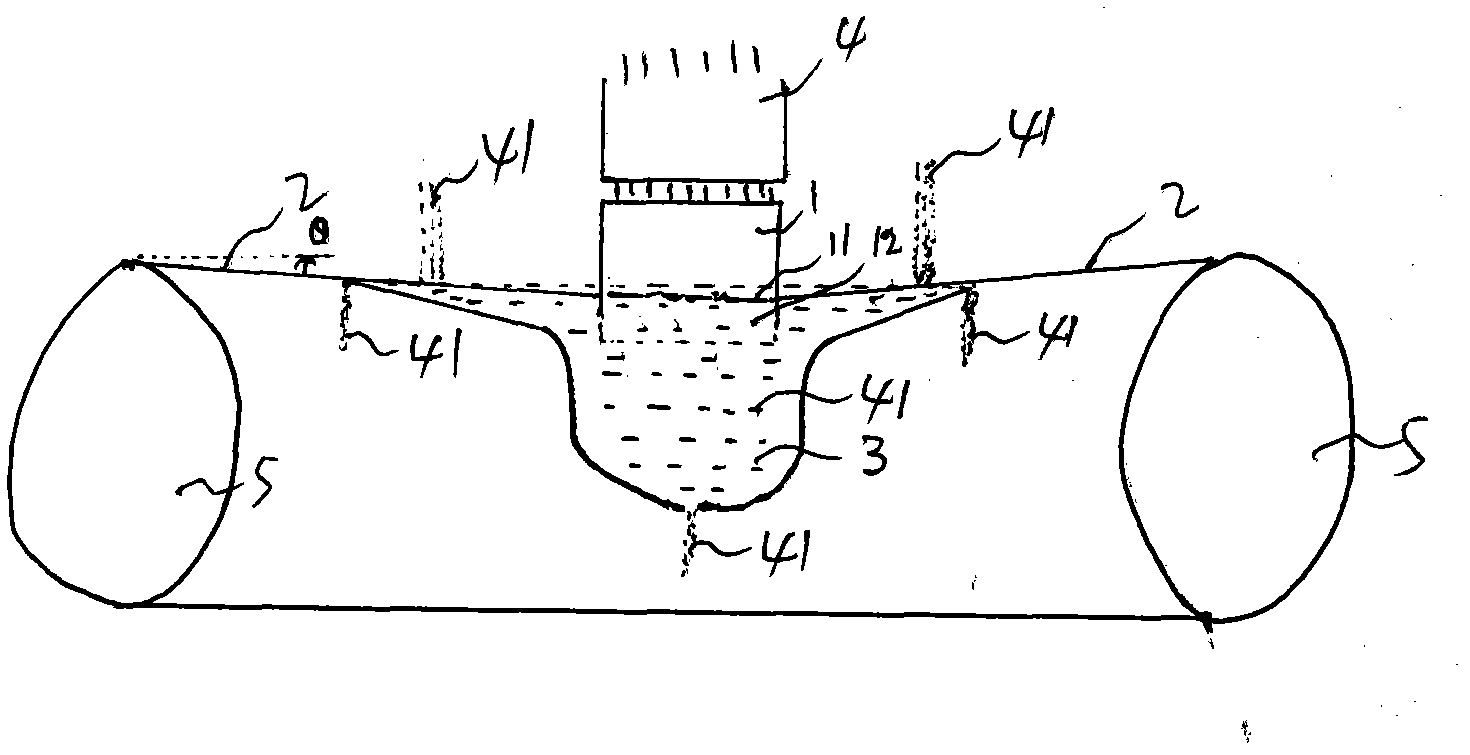

[0039] In a specific embodiment of the multi-wire cutting equipment used for cutting silicon wafers according to the present invention, the equipment includes a multi-wire cutting device, which includes at least two wire pulleys of the loading and moving drive system of the cutting wire net, wherein The horizontal position of the guide wheel is kept fixed, and the cutting wire is wound in the wire groove on the guide wheel; and the loading of the silicon ingot to be cut keeps the silicon ingot above the cutting wire net and can control the movement of the silicon ingot to the cutting wire net and its moving system, including a tooling fixture and a moving device for lifting the said tooling fixture; and a liquid holding tank and a loading system thereof arranged under the cutting side part of the cutting wire mesh to hold the cutting fluid, so that the cutting fluid can be u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com