Small building material grinding device for constructional engineering

A technology of building materials and construction engineering, applied in the direction of grain processing, etc., can solve the problems of material waste, blockage, and reduce the feeding efficiency of grinding discs, etc., and achieve the effect of reducing the feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

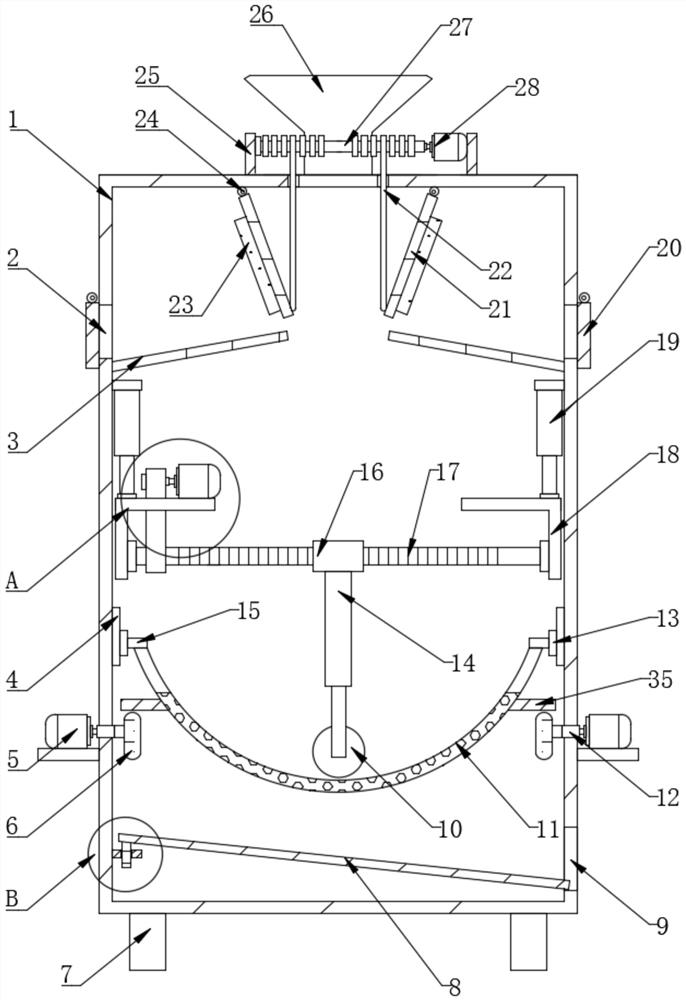

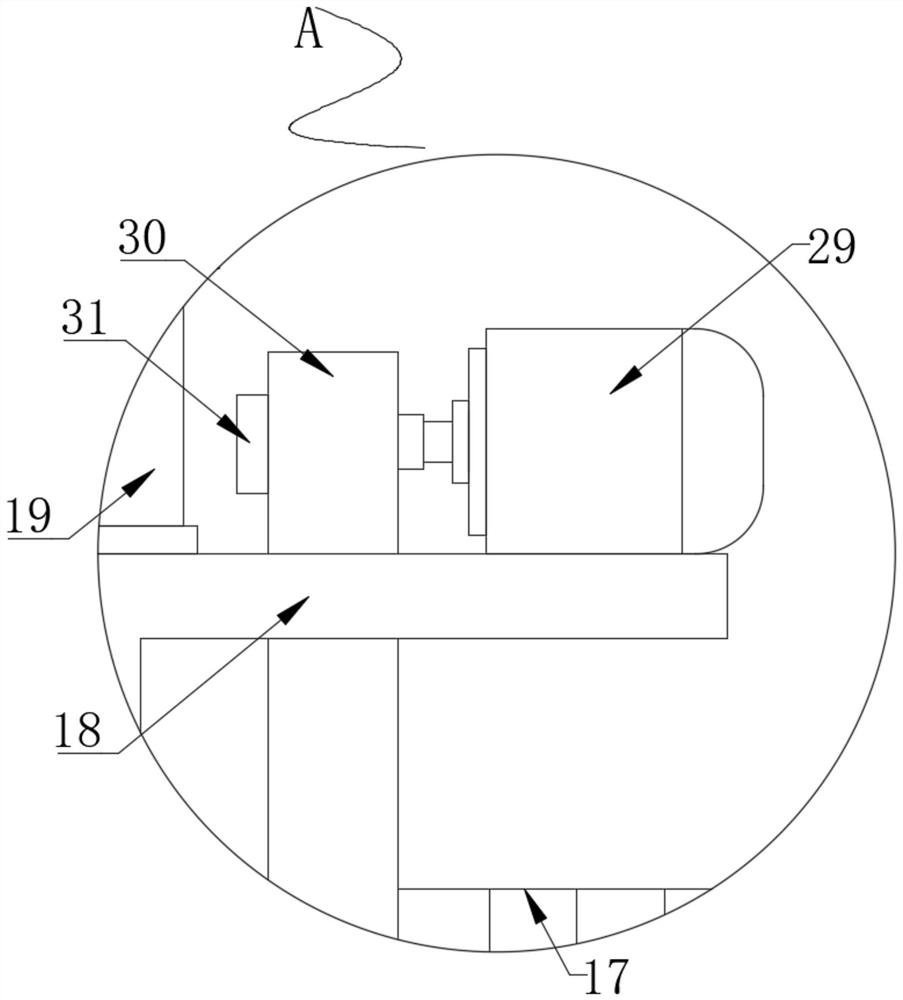

[0025] see Figure 1~4 , in an embodiment of the present invention, a small construction material grinding device for construction engineering, comprising a grinding box main body 1, the four corners of the bottom end of the grinding box main body 1 are connected with support feet 7, and the top of the grinding box main body 1 is provided with a lower hopper 26 The inner side of the grinding box main body 1 is provided with a grinding disc 11, the inner side of the grinding box main body 1 is provided with a screw mandrel 17, the outer side of the screw mandrel 17 is sleeved with a movable nut 16, and the bottom end of the movable nut 16 is connected with a telescopic rod 14. The bottom end of bar 14 is provided with grinding roller 10, and both sides of grinding box main body 1 are all equipped with first motor 5, both sides of grinding box main body 1 inner side are all provided with slide rail 4, and both sides of grinding box main body 1 inner side are all installed with H...

Embodiment 2

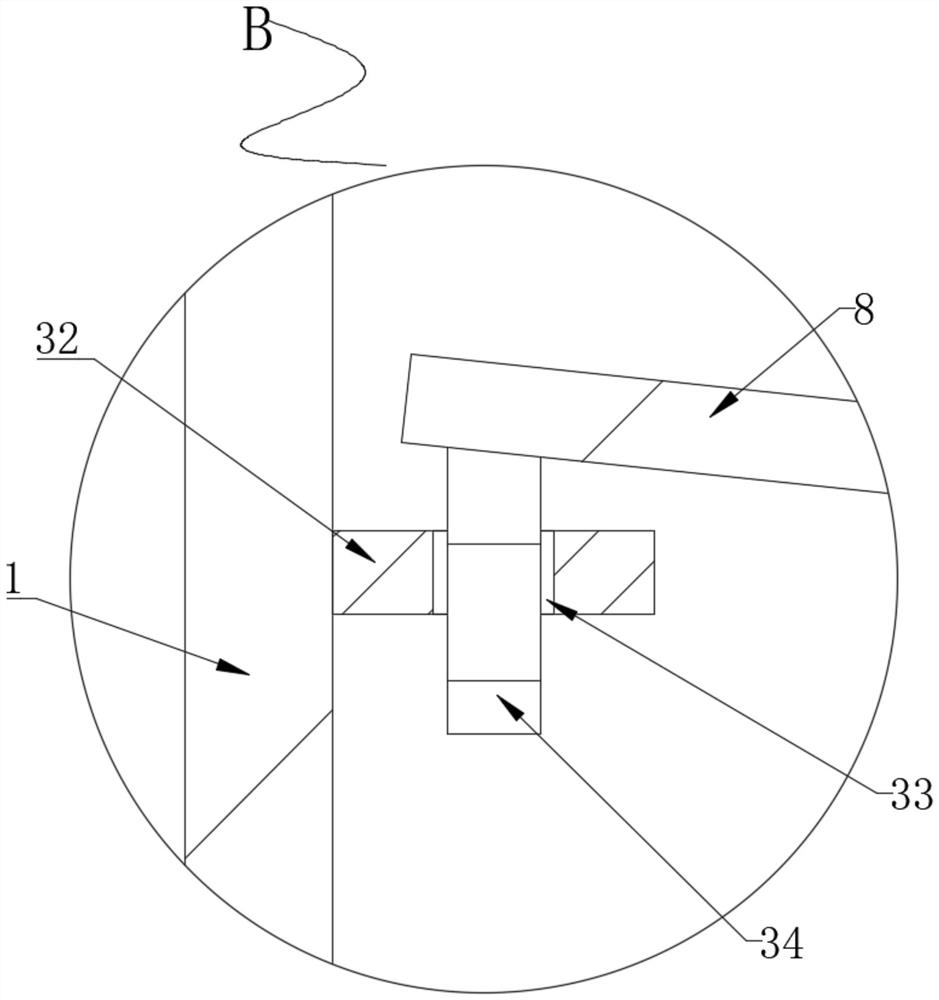

[0033] refer to figure 1 with 4 , a small construction material grinding device for construction engineering. Compared with Embodiment 1, this embodiment also includes a discharge port 9 at the bottom of one side of the main body of the grinding box 1, and a support plate is provided on one side of the main body of the grinding box 1. 32. The bottom of the inner side of the main body 1 of the grinding box is provided with a second material guide plate 8, and one side of the bottom end of the second material guide plate 8 is connected with two limit posts 34, and the top of the support plate 32 is provided with two limit jacks 33.

[0034] Wherein, the limit post 34 is arranged inside the limit jack 33 , and the second material guide plate 8 is firmly connected to the grinding box main body 1 through the cooperation of the support plate 32 , the limit jack 33 and the limit post 34 .

[0035] Working principle: when it is necessary to collect the ground building materials, a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com