High-speed reciprocation wire cut electrical discharge machining working solution service life online fast determining method

A reciprocating wire EDM technology, applied in the identification of the working state of the electrolyte used in wire EDM, and in the field of online rapid judgment of the life of the working fluid in high-speed reciprocating wire EDM, which can solve the problem of poor judgment accuracy and delay Problems such as non-resistance, inability to achieve cutting processing status, etc., to achieve the effect of reducing broken wires, prolonging the trouble-free working time and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

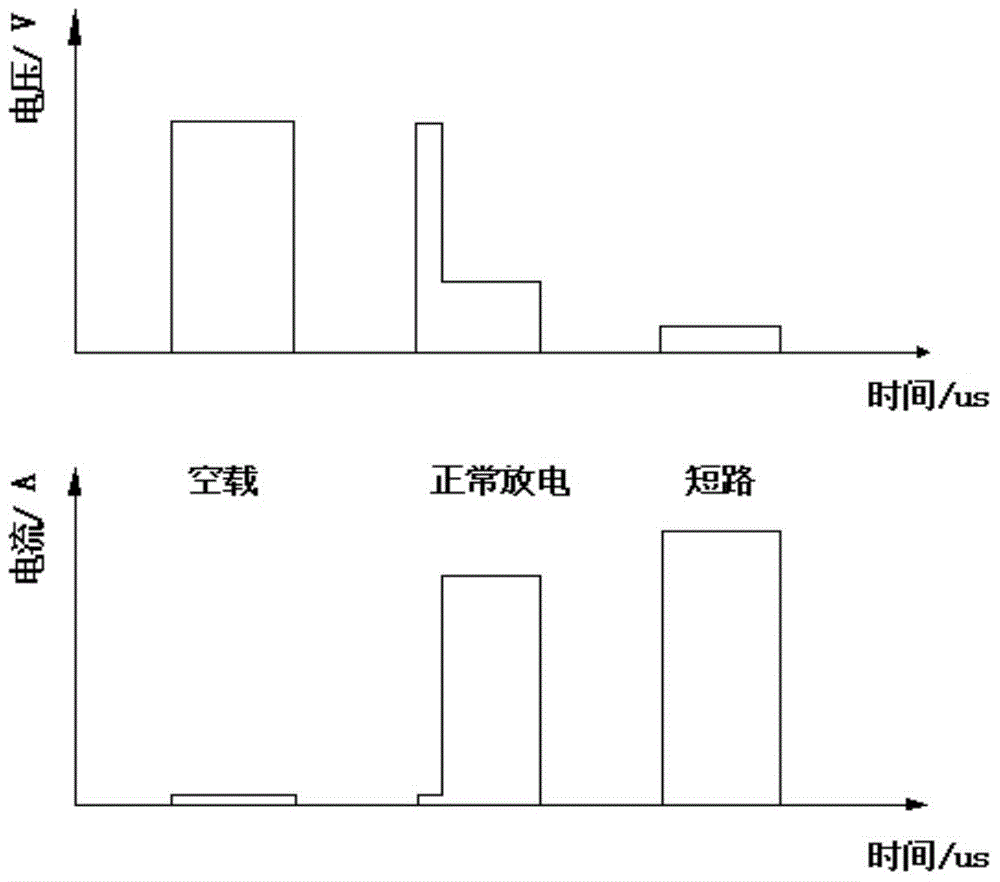

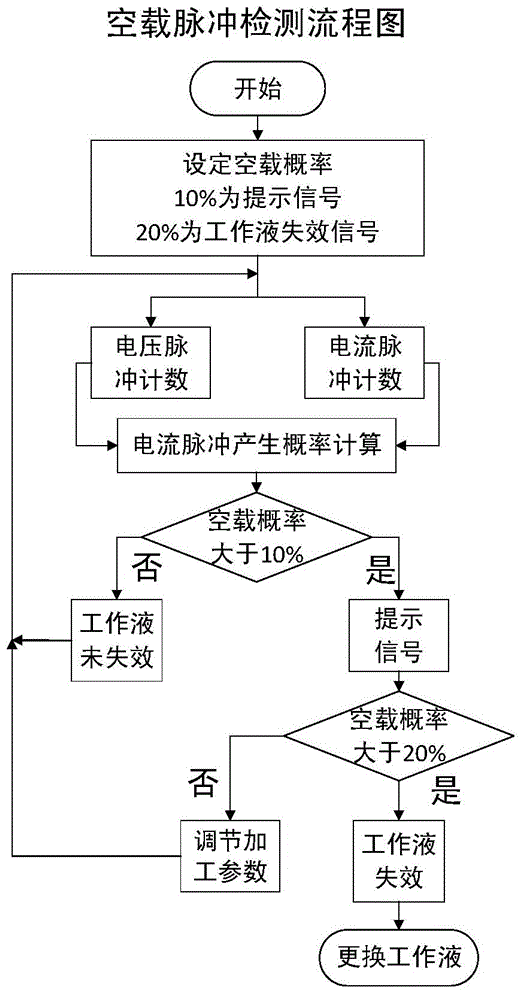

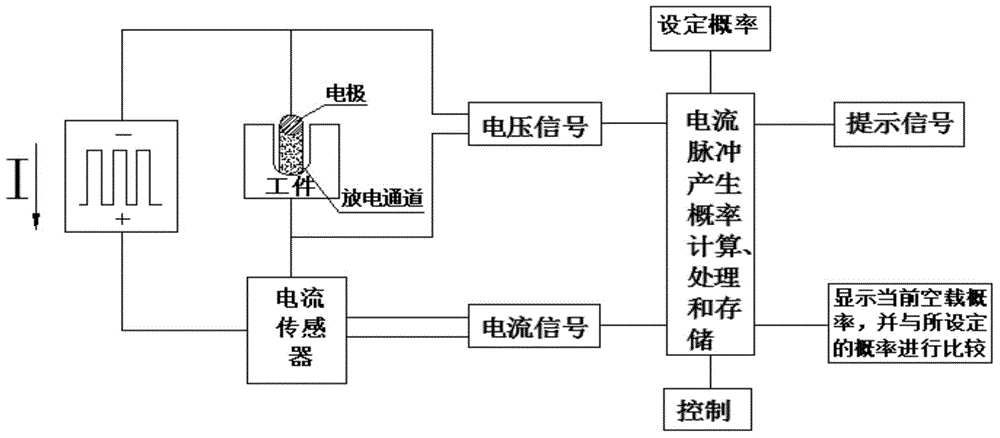

[0026] Such as Figure 1-4 shown.

[0027] A high-speed reciprocating wire electric discharge wire cutting machining working fluid life online rapid determination method, which includes the following steps:

[0028] First, through the sampling circuit (such as image 3 ) Collect the number of no-load current pulses or (short circuit + discharge) current pulses within a sampling period on a regular basis (can be set by yourself, such as intervals of 1 minute, 3 minutes, 5 minutes, 10 minutes or more);

[0029] Secondly, calculate the ratio of the number of no-load current pulses or (short circuit + discharge) current pulses to the pulses in a sampling period:

[0030] Third, according to the income ratio, the following processing is carried out:

[0031] If the no-load pulse ratio is ≤10% or (short circuit + discharge) pulse rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com