Production process of semiconductor-grade quartz ring

A production process and semiconductor technology, used in glass production, stone processing equipment, fine working devices, etc., can solve the problems of rough surface state, low dimensional accuracy, and high materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment is a production process of a semiconductor-grade quartz ring, comprising the following steps:

[0045] Step 1: Place one end of the quartz ingot on the conveying roller 310 of the crystal ingot cutting equipment, clamp it by the limit seat 303, put the other end of the quartz ingot into the inner cavity of the clamping mechanism 107, and clamp it by the clamping mechanism 107 , drive the quartz ingot to move to the top of the knife drop groove 308 by the moving motor 702 and the conveying motor 311, and cut the quartz ingot by the diamond cutting knife 304 to form a quartz wafer;

[0046] Step 2: Place the quartz wafer on the platform of the water jetting machine for inner and outer diameter processing to form a rough quartz ring with an inner and outer diameter allowance of 5mm for subsequent MC processing;

[0047] Step 3: Carry out plane grinding on the crude quartz ring to ensure that the flatness and parallelism requirements are within 0.02mm. After...

Embodiment 2

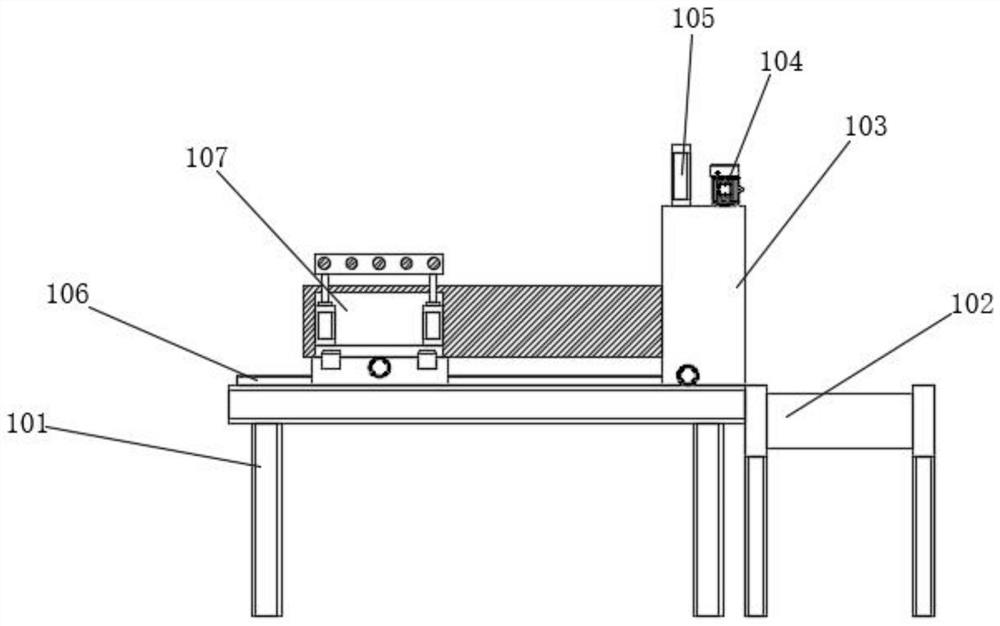

[0055] see Figure 1-8 As shown, the present embodiment is an ingot cutting equipment, including a mounting frame 101, a conveyor 102, a support frame 103, a cutting motor 104, a pressing cylinder 105, a slideway 106, and a clamping mechanism 107. One end of the mounting frame 101 is provided with a Conveyor 102, a support frame 103 is installed on the top of the end of the mounting frame 101 close to the conveyor 102, slideways 106 are installed on both sides of the top of the mounting frame 101 away from the end of the support frame 103, and a clamping mechanism is slidably connected to the slideway 106 107;

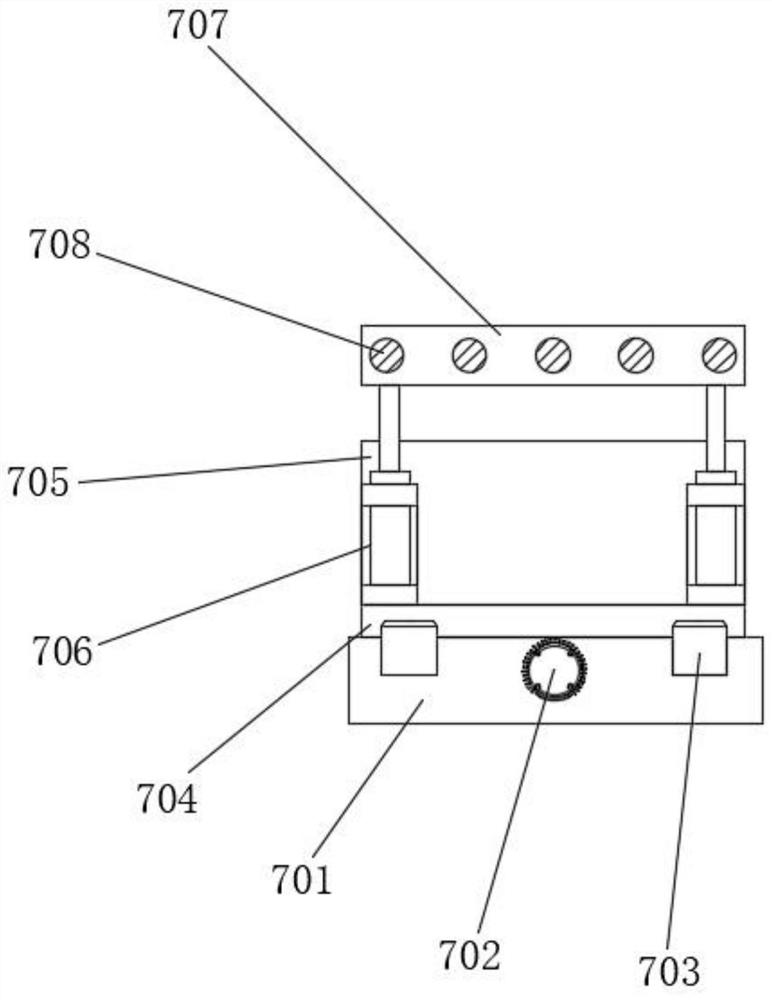

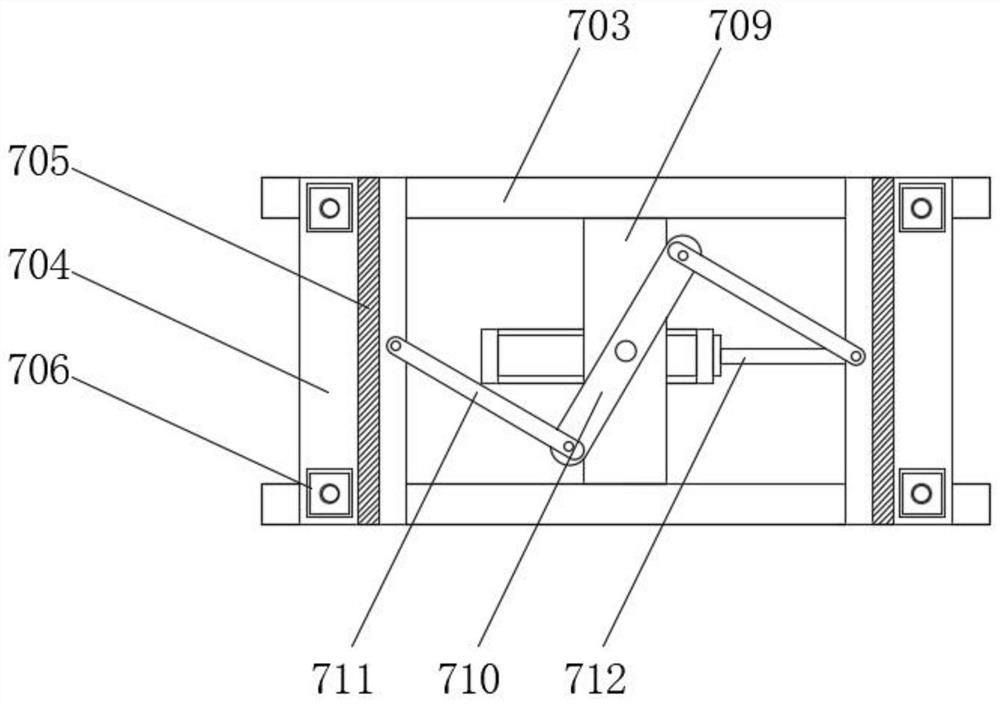

[0056] The clamping mechanism 107 includes a sliding base 701, a moving motor 702, a mounting rod 703, a mounting plate 704, a clamping plate 705, a stretching cylinder 706, a fixed plate 707, a fixed rod 708, a connecting plate 709, a turning plate 710, and a connecting arm 711 , clamping cylinder 712, transmission rod 713, gear column 714, toothed plate 715, the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com