Preparation method of high-safety lithium ion battery diaphragm and preparation of total battery

A lithium-ion battery and separator technology, applied in the field of new energy batteries, can solve the problems of flammability, volatility, poor safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: Preparation of polyaryletherketone material

[0034]

[0035] Feed bisphenol monomers containing allyl double bonds, difluorobenzophenone (or dichlorobenzophenone) and other bisphenol monomers into a three-necked flask at a molar ratio of 3:5:2, and simultaneously add Dimethyl sulfoxide (DMSO) or N-methylpyrrolidone with a mass ratio of 1.2 times is used as a solvent, toluene with a mass ratio of 0.3 to 0.5 times is used as a water carrier, and potassium carbonate with a molar ratio of 1.1 to 1.4 times that of dihalogenated benzophenone As a salt-forming agent, the temperature of the system was gradually raised to 160°C for 5 hours to react stably for 5 hours, until the system became viscous and uniform, and the reaction product was discharged into deionized water and washed repeatedly until the pH value was Neutral, dry the material for later use.

Embodiment 2

[0036] Embodiment 2: Preparation of polyaryletherketone nonwoven fabric

[0037] Dissolve the material prepared in Example 1 in organic solvents such as tetrahydrofuran, or 1,4-dioxane, or dimethylformamide, and prepare a homogeneous solution with a mass fraction of 10% or 20%. Electrospinning Silk machine made nonwoven materials, see figure 2 with image 3 .

[0038] Electrospinning machine parameter setting: set positive and negative electrode electrostatic voltage 10KV ~ 15KV, spinning rate 2mL / min, roller receiving speed 200 ~ 400r / min, distance between nozzle and roller 15cm ~ 30cm. By specifically adjusting the above parameters, non-woven materials with different fiber diameters (1 μm-3 μm), different liquid absorption rates (50%-80%), and different mechanical strengths can be obtained. The finally obtained non-woven material was dried at 60° C. under vacuum for 24 hours, and kept for future use.

Embodiment 3

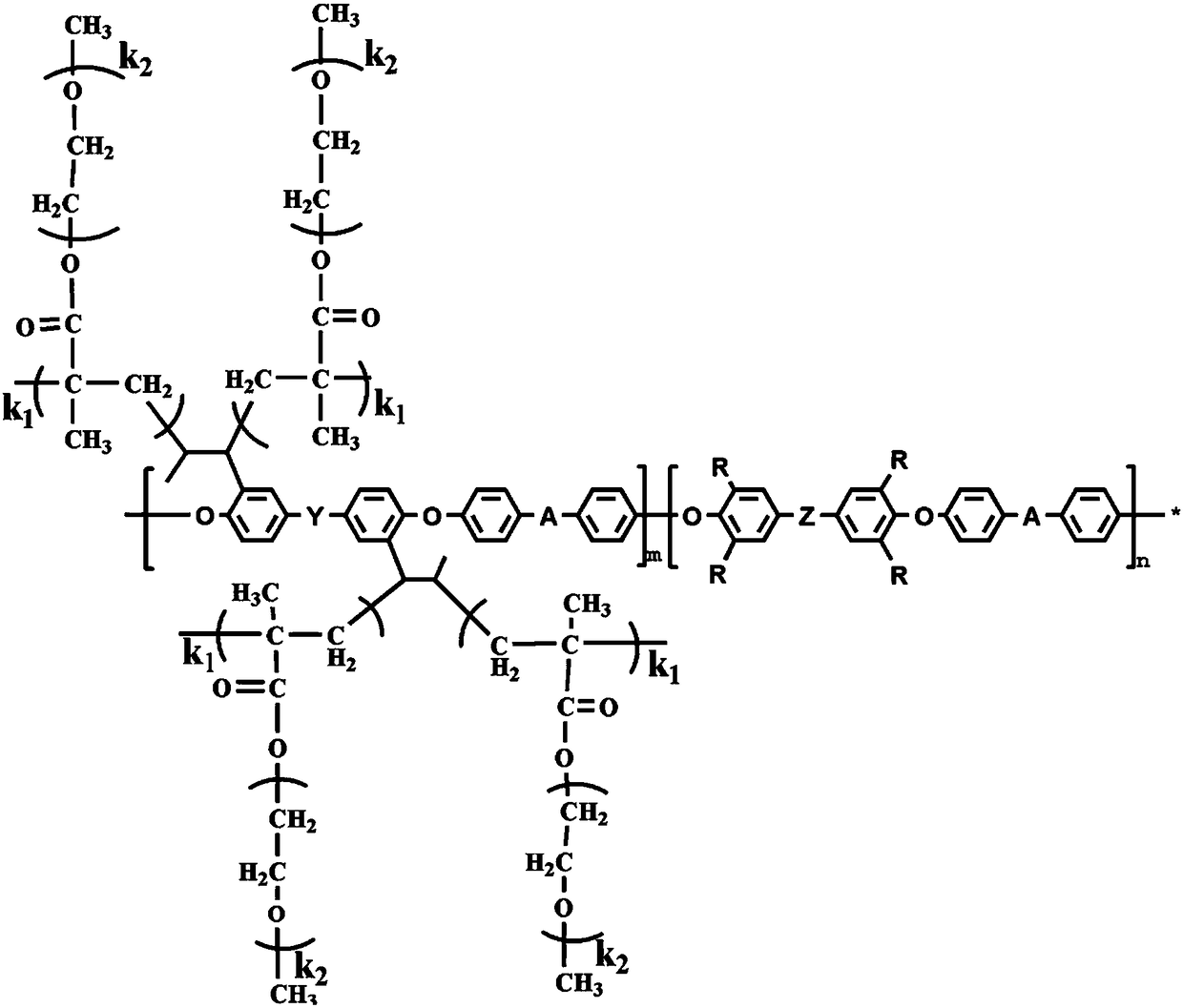

[0039] Example 3: Preparation of Gel Electrolyte Containing Flexible Side Chain Structure Crosslinked Polymer

[0040] Based on the polyaryletherketone nonwoven material prepared in Example 2, polyethylene glycol acrylate and commercial lithium ion electrolyte were mixed according to the mass ratio of 40:60, and 1% of curing agent was added, and the mixed The system is added to the non-woven fabric according to a certain mass ratio, and is cured by ultraviolet light or heat to finally prepare a cross-linked polymer gel electrolyte diaphragm material containing flexible side chains. The reaction formula and the structure of the cross-linked polymer that contains flexible PEG (polyethylene glycol) side chains are prepared as follows:

[0041]

[0042] k 2 = 4 or 6, k 1 is a positive integer greater than 1.

[0043] At the same time, the fire resistance test was carried out on the material, such as Figure 4 As shown, the gel electrolyte separator and the liquid electrolyt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com